In the relentless pursuit of materials that can withstand extreme conditions, researchers have made a significant stride in the development of heat-resistant concrete (HRC), a breakthrough that could redefine construction standards in high-temperature industries. Tejas Joshi, a researcher at the Institute of Technology, Nirma University in Ahmedabad, India, has led a study that delves into the performance of HRC under varying temperature conditions, offering promising insights for sectors such as metallurgy, power generation, and construction.

Traditional concrete, while robust under normal conditions, tends to degrade when exposed to high temperatures, leading to structural weaknesses and potential failures. Joshi’s research, published in the journal *Advances in Civil and Architectural Engineering* (translated as *Advances in Civil and Architectural Engineering*), explores innovative mix designs that enhance thermal stability, ensuring durability and strength even in extreme heat.

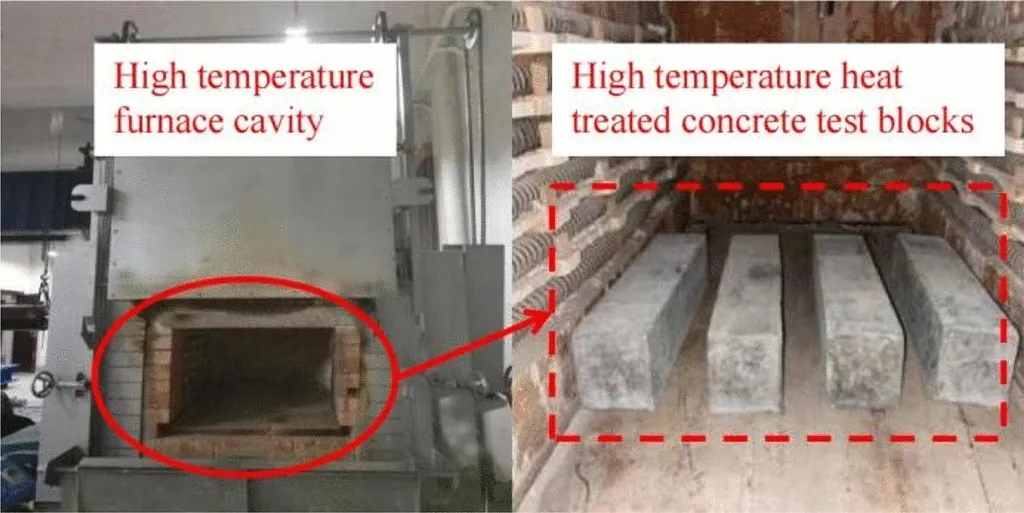

The study involved creating three distinct concrete mix designs, each subjected to controlled heating to evaluate their compressive strengths against a control concrete. The findings revealed that concrete incorporating basalt aggregates demonstrated superior thermal performance compared to those with natural aggregates. “The use of basalt aggregates, combined with high-temperature-resistant binders like Portland slag cement, significantly improved the thermal stability of the concrete,” Joshi explained. “This combination not only enhanced the material’s resistance to high temperatures but also optimized strength retention across various curing and heating conditions.”

One of the key discoveries was the optimal binder content of 420 kg/m³, which showed remarkable strength retention when exposed to temperatures as high as 700°C. This finding is particularly relevant for industries where thermal endurance is critical. “The ability to maintain structural integrity under such extreme conditions opens up new possibilities for construction in high-temperature environments,” Joshi added.

The implications of this research are far-reaching. For the energy sector, which often operates in extreme thermal conditions, the development of HRC could lead to more durable and reliable infrastructure. Power plants, for instance, could benefit from structures that can withstand the intense heat generated during operations, reducing maintenance costs and enhancing safety.

Moreover, the use of basalt aggregates and Portland slag cement not only improves thermal performance but also aligns with sustainable construction practices. As industries increasingly prioritize eco-friendly materials, the adoption of HRC could contribute to greener building practices without compromising on strength and durability.

Joshi’s research underscores the importance of continuous innovation in materials science to meet the evolving demands of various industries. As the world grapples with the challenges of climate change and the need for sustainable infrastructure, the development of heat-resistant concrete represents a significant step forward. “This research is just the beginning,” Joshi noted. “There is still much to explore in terms of optimizing mix designs and exploring new materials that can further enhance the performance of HRC.”

In conclusion, the study by Tejas Joshi and his team at the Institute of Technology, Nirma University, highlights the potential of heat-resistant concrete to revolutionize construction in high-temperature industries. As the energy sector continues to evolve, the adoption of such innovative materials could pave the way for more resilient and sustainable infrastructure, ultimately benefiting both industry and the environment.