In the quest to enhance the durability of materials used in extreme environments, a team of researchers led by Yudong Li from Sichuan University has uncovered critical insights into how irradiation affects the corrosion resistance of a promising steel alloy. Their findings, published in *Materials Research Express* (which translates to “Materials Research Express” in English), could have significant implications for the energy sector, particularly in advanced nuclear reactor designs.

The study focused on 12Cr ferritic/martensitic (F/M) steel, a material known for its potential use in next-generation nuclear reactors due to its high strength and resistance to radiation damage. However, these reactors often utilize lead-bismuth eutectic (LBE) as a coolant, which can corrode steel over time. The team investigated how gold-ion irradiation—simulating the damage caused by high-energy particles in a reactor—affects the steel’s microstructure and its ability to withstand LBE corrosion.

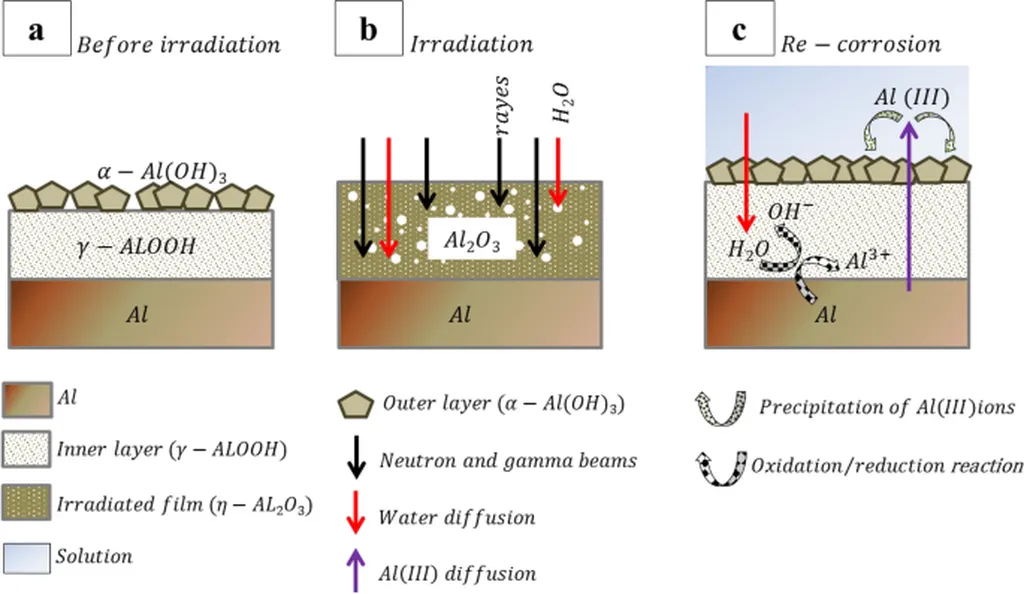

“Our research revealed that irradiation induces significant changes in the steel’s microstructure, including the formation of dislocation loops and networks, as well as the amorphization of certain precipitates,” explained Li. These changes, while strengthening the material, also create additional pathways for elemental diffusion, accelerating corrosion when the steel is exposed to LBE.

The team found that while the overall structure of the oxide layers formed on the steel’s surface remained unchanged after irradiation, the layers grew thicker. This increase in thickness is a direct result of the irradiation-induced defects, which provide more routes for elements to diffuse, speeding up the corrosion process.

The implications of this research are profound for the energy sector. As nuclear reactors evolve, the materials used in their construction must withstand increasingly harsh conditions. Understanding how irradiation affects corrosion resistance is crucial for designing safer, more efficient reactors. “This work provides a foundation for developing strategies to mitigate irradiation-accelerated corrosion in advanced nuclear systems,” Li noted.

The findings could also influence other industries where materials are exposed to extreme environments, such as aerospace and high-temperature manufacturing. By tailoring the microstructure of materials to resist both irradiation and corrosion, engineers could extend the lifespan of critical components, reducing maintenance costs and improving safety.

As the world looks to advanced nuclear energy as a key part of a sustainable energy mix, research like this is invaluable. It not only deepens our understanding of material behavior but also paves the way for innovations that could shape the future of energy production.