In the quest for safer and more efficient energy solutions, the detection of volatile and flammable solvents like ethanol is paramount. A recent study published in *Materials Research Express* (which translates to *Materials Research Express* in English) has unveiled a promising advancement in gas-sensing technology that could significantly impact the energy sector. Led by Xianjun Zheng from the CATARC Automotive Component Test Center (Ningbo) Co., Ltd, the research introduces a novel method for synthesizing spherical tin dioxide (SnO₂) particles with enhanced gas-sensing capabilities.

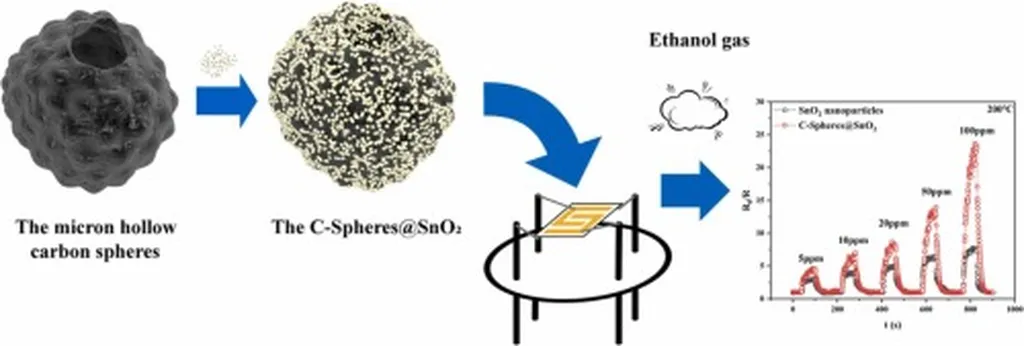

Ethanol, widely used in various industries, poses serious environmental and safety risks when leaked. Traditional SnO₂ sensors often fall short due to low sensitivity and poor stability, primarily because of their limited surface area and irregular morphology. Zheng and his team addressed these issues by developing a surfactant-free hydrothermal method to create uniform spherical SnO₂ particles, each approximately 0.25 micrometers in size. These particles are composed of fine grains around 4 nanometers, boasting a high specific surface area of 232.20 m²/g. This large surface area provides abundant active sites for gas adsorption, significantly improving the sensor’s performance.

The sensor demonstrated excellent selectivity and rapid response to ethanol, achieving a response of 48.28 at 100 parts per million (ppm) with a response/recovery time of 4/15 seconds at 300°C. Notably, it can detect ethanol concentrations as low as 2 ppm. “The enhanced performance is attributed to the large surface area, high porosity, and efficient gas diffusion of the spherical structure,” Zheng explained. This breakthrough could revolutionize the way industries monitor and manage ethanol leaks, ensuring safer operations and reduced environmental impact.

The implications of this research extend beyond ethanol detection. The surfactant-free synthesis method offers a simple and scalable approach to fabricating high-performance SnO₂-based gas sensors. This could pave the way for more reliable and efficient gas-sensing technologies across various applications, from industrial safety to environmental monitoring.

As the energy sector continues to evolve, the demand for advanced sensing technologies will only grow. Zheng’s work not only addresses current challenges but also sets the stage for future innovations. “This study provides a foundation for developing next-generation gas sensors that are both highly sensitive and stable,” Zheng noted. With further research and development, these sensors could become integral components in the safety and efficiency protocols of energy production and storage facilities worldwide.

Published in *Materials Research Express*, this research highlights the potential of nanotechnology in enhancing gas-sensing performance. As industries strive for safer and more sustainable practices, such advancements are crucial. The study by Zheng and his team offers a glimpse into a future where advanced materials and innovative technologies work hand in hand to create a safer and more efficient energy landscape.