In the heart of China, researchers at the School of Mechanical Engineering, Sichuan University of Science & Engineering, are making waves in the world of materials science. Led by Xiong Can, a team of scientists has been delving into the fascinating realm of superhydrophobic surfaces, specifically for copper alloys. Their work, recently published in *Cailiao Baohu* (which translates to *Materials Protection*), could have significant implications for industries like shipbuilding and electric power, where copper alloys are widely used.

Copper alloys are prized for their excellent electrical conductivity, thermal conductivity, and ductility. However, they are not without their challenges. In harsh environments, such as low temperatures or high salinity, these alloys can suffer from corrosion, frost formation, and fouling. These issues not only reduce the service life of the materials but also limit their range of applications.

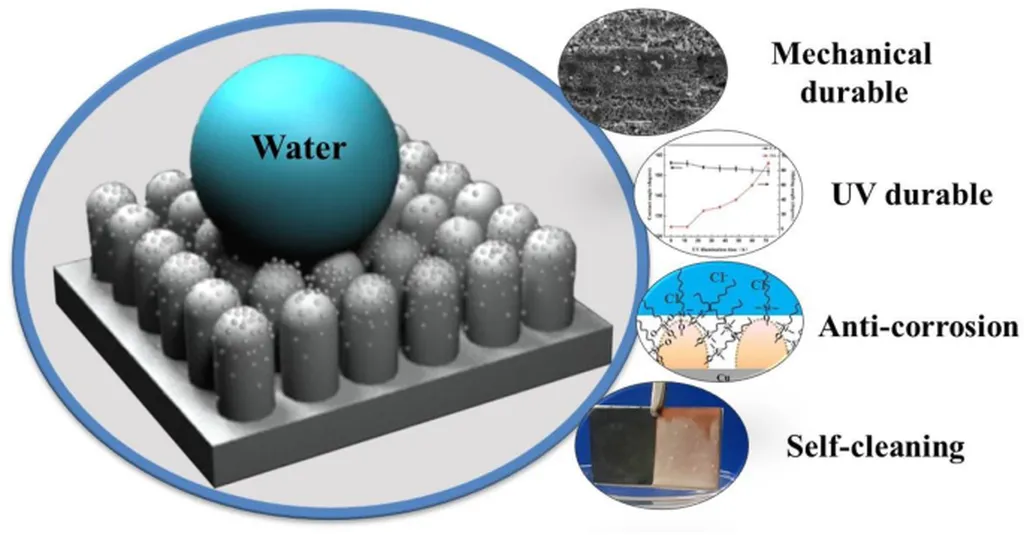

Enter superhydrophobic surfaces. By modifying the surface of copper alloys, researchers can enhance their wettability, composition, and micro-morphology. This, in turn, can improve the service performance of copper-based metals. As Xiong Can explains, “The superhydrophobic modification of copper and its alloy surfaces can effectively improve their surface energy, composition, and micro-morphology, thereby enhancing the service performance of copper-based metals.”

The team has been exploring various preparation methods, including etching, electrodeposition, and oxidation. Each method has its own advantages and limitations, but the goal is the same: to create surfaces that repel water so effectively that they remain dry even when submerged.

The potential applications of this technology are vast. In the energy sector, for instance, superhydrophobic copper alloys could be used to create more efficient and durable power generation and transmission equipment. In shipbuilding, they could help prevent biofouling, reducing the need for frequent cleaning and maintenance.

But the journey is not without its challenges. As the researchers note, achieving high durability and multifunctionality of copper alloy superhydrophobic surfaces, along with innovating preparation technologies, is crucial for promoting their development and application.

The team’s work is a testament to the power of innovation in materials science. As they continue to push the boundaries of what’s possible, they are not only advancing our understanding of superhydrophobic surfaces but also paving the way for a future where copper alloys can withstand even the harshest environments.

In the words of the researchers, “Overall, achieving high durability, multifunctionality of copper alloy superhydrophobic surfaces and innovation in preparation technologies is of great significance for promoting their development and application.” With their groundbreaking work, they are well on their way to making that vision a reality.