In the realm of medical materials science, a groundbreaking study led by Yuechuan Li from the Key Laboratory for Biorheological Science and Technology of Ministry of Education at Chongqing University has unveiled a novel biodegradable zinc alloy that could revolutionize the design of biliary stents. Published in the esteemed journal *Bioactive Materials* (translated from Chinese as *活性材料*), this research opens new avenues for medical device innovation, with potential ripple effects across the healthcare and energy sectors.

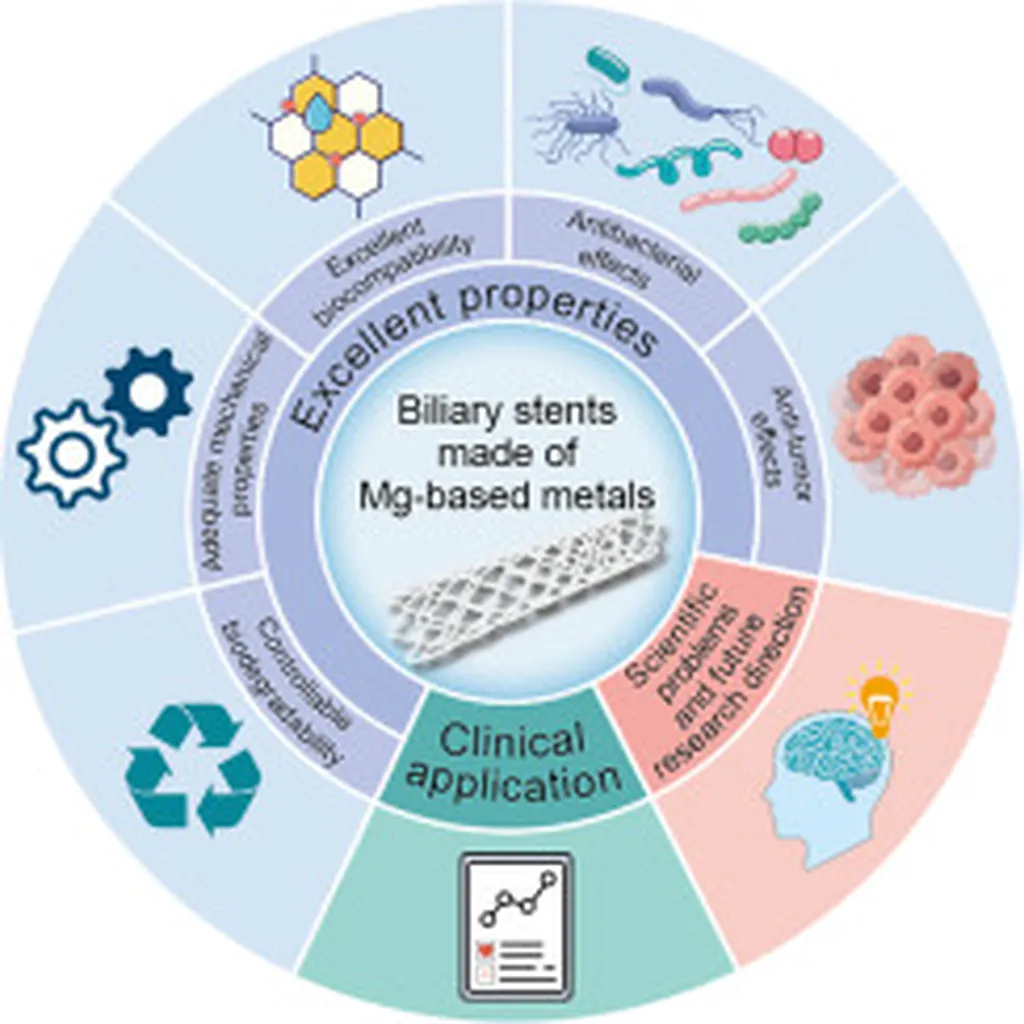

Biliary stents are crucial for treating bile duct obstructions, but current biodegradable options often fall short of clinical demands. Li and his team have developed a zinc-copper alloy with a trace addition of boron, enhancing its mechanical properties and biocompatibility. “The incorporation of boron significantly refined the grain size and introduced a bimodal organization, which greatly improved the alloy’s mechanical properties,” Li explained. This refinement led to substantial increases in yield strength, ultimate tensile strength, and elongation, making the alloy a promising candidate for biliary stents.

The study also revealed that the addition of boron reduced the alloy’s corrosion resistance, making it more hydrophilic. This property is crucial for medical implants, as it ensures better integration with bodily tissues. In vitro evaluations showed that the Zn-0.8Cu-0.03B alloy exhibited excellent biocompatibility and strong antibacterial properties, inhibiting the growth of Staphylococcus aureus and Escherichia coli.

In vivo tests in rabbits demonstrated the alloy’s potential for clinical use. The stents maintained structural integrity for three weeks before degrading completely within eight weeks. Importantly, the degradation products were safely eliminated without causing biliary stricture or obstruction, and tissue hyperplasia induced by the stent was effectively alleviated. “The degradation behavior and biological properties of this alloy make it a strong contender for next-generation biliary stents,” Li noted.

The implications of this research extend beyond the medical field. The development of biodegradable materials with controlled degradation rates and excellent biocompatibility could inspire innovations in other sectors, including energy. For instance, similar alloys could be used in temporary structural applications where biodegradability is advantageous, such as in environmental remediation or sustainable energy storage solutions.

As the world seeks more sustainable and efficient materials, the work of Li and his team underscores the importance of interdisciplinary research. By bridging the gap between materials science and medical technology, this study not only advances the field of biodegradable implants but also paves the way for broader applications in energy and environmental sectors. The future of medical and industrial materials looks brighter with these innovative alloys leading the charge.