In the quest for sustainable and high-performance materials, researchers have turned to natural fibers as a promising alternative to traditional reinforcements in polymer composites. A recent study led by Ilham Essaket from the Laboratory REMTEX at the Higher School of Textile and Clothing Industries in Casablanca, Morocco, has shed light on the potential of sisal fibers to enhance the physicomechanical properties of polyester composites. The findings, published in the Journal of Engineered Fibers and Fabrics (translated to English as “Journal of Engineered Fibers and Fabrics”), offer valuable insights for industries seeking durable and eco-friendly materials, particularly in the energy sector.

Essaket and her team focused on improving the adhesion between sisal fibers and polyester matrices through chemical treatments. The researchers first mercerized the sisal fibers, a process involving the use of alkali, and then modified them using potassium permanganate (KMnO₄) and sodium chlorite. This dual treatment aimed to enhance the fibers’ interaction with the polymer matrix, ultimately improving the composite’s mechanical properties.

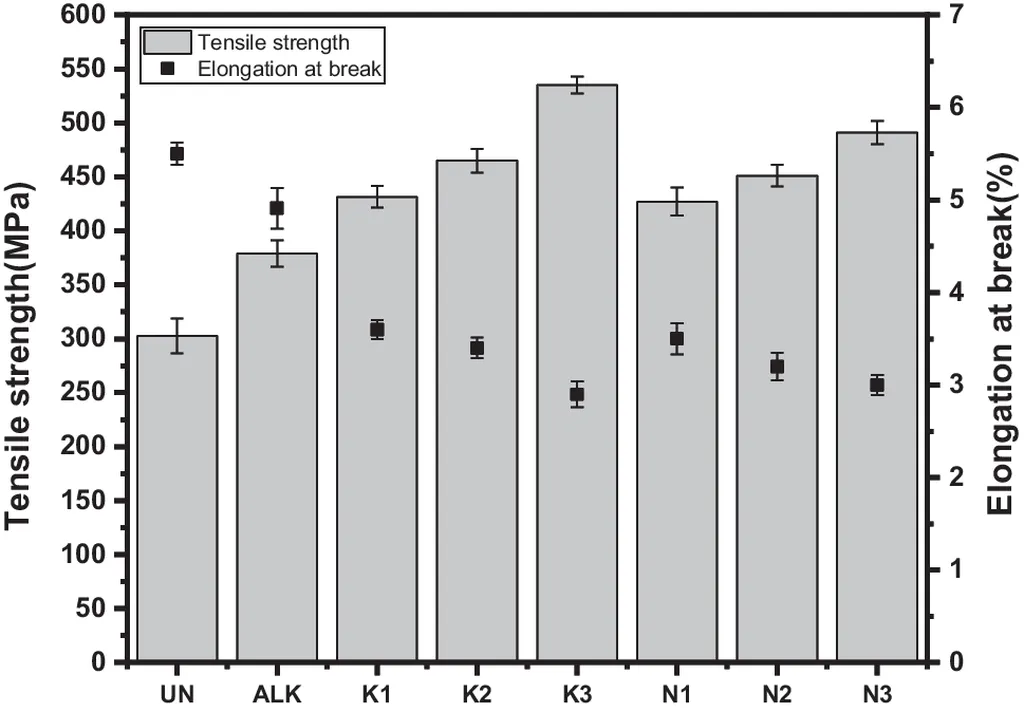

The results were striking. The tensile strength of the composites saw a significant boost, with the alkali treatment alone increasing it from 129.31 MPa to 266.12 MPa. The addition of KMnO₄ further elevated the tensile strength to 359.11 MPa. “The improvement in tensile strength is a clear indication of the enhanced interfacial bonding between the fibers and the matrix,” Essaket explained. This enhanced bonding not only improves the mechanical performance but also contributes to the durability of the composites in aggressive environments.

Water absorption, a critical factor for materials used in marine and structural applications, was also addressed. The treatments reduced water uptake, but an increase was observed with rising temperatures from 18°C to 40°C. Despite this, the overall improvement in water resistance suggests that these composites could be suitable for applications where exposure to saline environments is inevitable.

Scanning Electron Microscopy (SEM) analysis confirmed the improved interfacial bonding, while Thermogravimetric Analysis (TGA) revealed enhanced thermal stability, particularly in the alkali- and KMnO₄-treated composites. The combined alkali and KMnO₄ treatment offered the most balanced improvement, highlighting its potential for marine and structural applications where durability and resistance to aggressive conditions are required.

The implications of this research are far-reaching, particularly for the energy sector. As the demand for renewable energy sources grows, so does the need for durable and sustainable materials for wind turbine blades, offshore structures, and other energy-related applications. The enhanced mechanical properties and durability of these sisal-reinforced polyester composites make them a viable option for such uses.

Essaket’s work underscores the importance of ongoing research in natural fiber composites. “The potential of natural fibers is vast, and with the right treatments, we can unlock their full potential,” she said. This research not only advances our understanding of sisal fibers but also paves the way for future developments in sustainable materials for various industries.

As the world continues to seek eco-friendly and high-performance materials, the findings from Essaket’s study offer a promising pathway. The enhanced properties of these composites could revolutionize the energy sector, providing durable and sustainable solutions for the challenges of tomorrow. With further research and development, sisal-reinforced polyester composites could become a cornerstone in the quest for sustainable and high-performance materials.