In the world of transport and hydraulic construction, the battle against water damage is an ongoing challenge. Structures like bridges, tunnels, and dams require robust waterproofing to ensure longevity, but traditional methods often fall short, leading to premature deterioration. Enter Mykola Harkusha, a researcher from the National Transport University in Kyiv, Ukraine, who has been delving into the potential of methyl methacrylate-based waterproofing membranes to revolutionize the industry.

Harkusha’s research, published in the journal ‘Дороги і мости’ (which translates to ‘Roads and Bridges’), focuses on the critical need for reliable waterproofing in transport and hydraulic structures. “The premature destruction of waterproofing is one of the least durable elements of the span structure,” Harkusha explains. This vulnerability not only compromises the integrity of the structures but also incurs significant repair costs for the energy and transport sectors.

The key to Harkusha’s approach lies in the internal structure and quality indicators of waterproofing materials. He emphasizes that the stability of these materials under various external and internal changes is paramount. “The relationship is established with optimal structures, when stable bonds in them ensure the stability of the main properties during various external and internal changes in the material in the structures,” he notes.

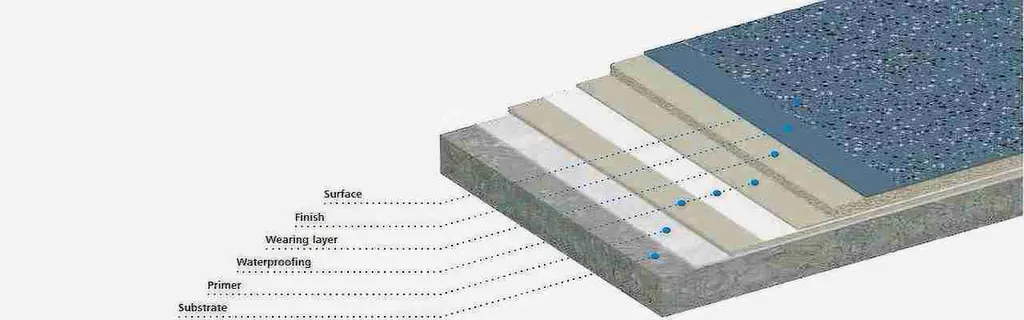

One of the most promising advancements in this field is the use of liquid composite membranes based on polyurethane and methyl methacrylate resins. These membranes form a continuous, seamless structure on surfaces of complex shapes, applied through liquid spraying. This innovation could significantly enhance the durability and performance of waterproofing systems in transport and hydraulic construction.

Harkusha’s research is not just about identifying the right materials but also about understanding the factors that influence the durability of these membranes. His work aims to develop a technology for installing waterproofing membranes based on methyl methacrylate resin and to establish requirements for their use. This could pave the way for more resilient and long-lasting structures, reducing maintenance costs and improving safety.

The implications for the energy sector are substantial. Hydraulic structures, such as dams and hydroelectric power plants, are critical components of the energy infrastructure. Ensuring their longevity through advanced waterproofing technologies can lead to more reliable and cost-effective energy production. Moreover, the transport sector stands to benefit from more durable bridges and tunnels, reducing downtime and repair expenses.

Harkusha’s research is a stepping stone towards a future where waterproofing is no longer a weak link in the chain of structural integrity. As the industry continues to evolve, his findings could shape the development of new materials and technologies, ensuring that transport and hydraulic structures stand the test of time. In the words of Harkusha, “The most advanced in terms of ensuring the protection of the slab are liquid composite membranes based on polyurethane and methyl methacrylate resins.” This statement encapsulates the potential of his research to transform the field and drive innovation in waterproofing technologies.