In the ever-evolving landscape of materials science, a groundbreaking study led by Hang Z. Yu of Virginia Tech’s Department of Materials Science and Engineering is turning heads. Published in the esteemed journal *Materials Research Letters* (translated to English as “Letters on Materials Research”), Yu’s work delves into the non-equilibrium processing science behind additive friction stir deposition (AFSD), a cutting-edge manufacturing technique that could revolutionize the energy sector.

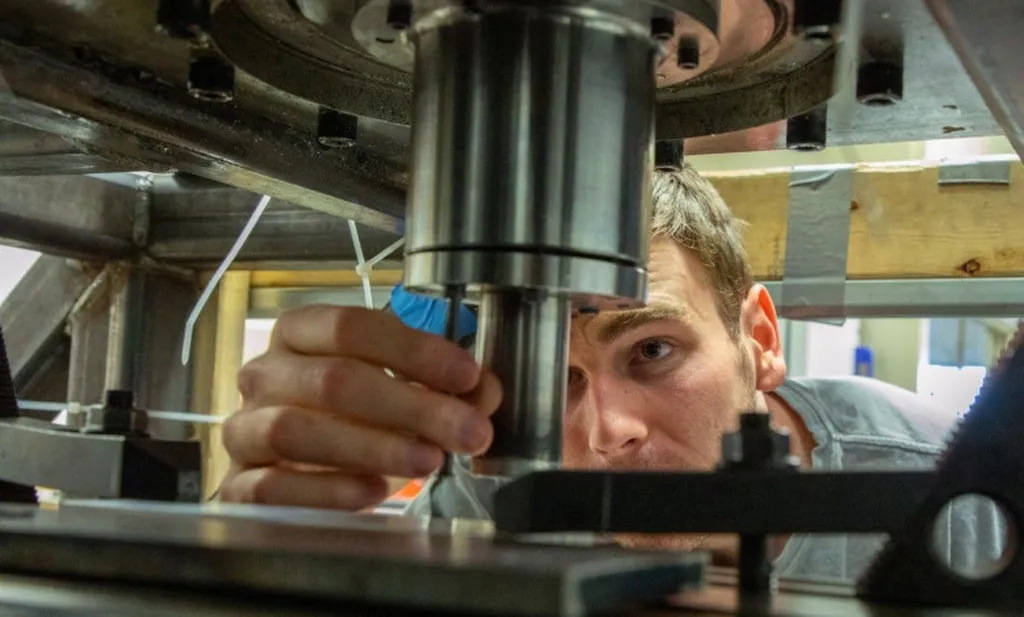

At the heart of Yu’s research lies the exploration of unique shear-driven kinetic pathways that enable the synthesis of new materials. Unlike traditional methods, AFSD subjects materials to extreme thermal and deformation histories, creating conditions far from equilibrium. “We’re talking about a process that’s fundamentally different from anything we’ve seen before,” Yu explains. “It’s like comparing a gentle breeze to a hurricane in terms of the forces and temperatures involved.”

The study breaks down the AFSD process into distinct stages, each governed by different mechanisms. The initial shear-driven stage is characterized by unique atom transport processes, while subsequent stages are dominated by thermally activated phenomena. This interplay between shear and thermal processes gives rise to novel phase and microstructural states, offering unprecedented control over material properties.

So, what does this mean for the energy sector? The implications are vast. AFSD’s ability to synthesize and print bulk-scale alloys with novel, non-equilibrium defect phases could lead to the development of advanced materials tailored for extreme environments. Imagine components for power plants or renewable energy systems that are stronger, more durable, and better equipped to withstand harsh conditions. “The potential is enormous,” Yu says. “We’re not just talking about incremental improvements. This could be a game-changer.”

The scalability of AFSD is another critical factor. Unlike some advanced manufacturing techniques that are limited to small-scale applications, AFSD can produce large components, making it a viable option for industrial-scale production. This scalability, combined with the unique properties of the materials produced, could significantly reduce costs and improve efficiency in the energy sector.

Yu’s research is not just about understanding the science behind AFSD; it’s about leveraging that understanding to push the boundaries of what’s possible. By exploring the non-equilibrium processing science, Yu and his team are paving the way for a new era of materials innovation. “We’re at the beginning of a very exciting journey,” Yu notes. “The possibilities are endless, and we’re just starting to scratch the surface.”

As the energy sector continues to evolve, the need for advanced materials that can meet the demands of a changing world becomes ever more critical. Yu’s work on additive friction stir deposition offers a glimpse into a future where materials are not just stronger and more durable but also tailored to specific applications, opening up new avenues for innovation and growth. The research, published in *Materials Research Letters*, is a testament to the power of scientific inquiry and its potential to shape the future of the energy sector.