In a groundbreaking study published in *Materials Research Express* (which translates to *Materials Research Express* in English), researchers have unlocked a novel approach to enhance the performance of ZL205A cast aluminum alloy, a material widely used in the energy sector. The key lies in optimizing pore architecture before applying hot isostatic pressing (HIP), a process that has been a staple in manufacturing for decades. This innovation, led by Peng Zhou from the School of Aeronautical Materials Engineering at Xi’an Aeronautical Polytechnic Institute in China, promises to revolutionize the way we think about material densification and corrosion resistance.

Traditionally, HIP has been used to eliminate internal voids in castings by applying high pressure and temperature. However, interconnected pores within the material can hinder complete densification due to internal pressure equilibrium. Zhou and his team discovered that by introducing sealed pores before the HIP process, they could significantly enhance the effective pressure differential, promoting creep-induced pore closure. “Unlike conventional methods, our approach leverages the strategic design of pore structures to overcome the limitations of traditional HIP,” Zhou explained.

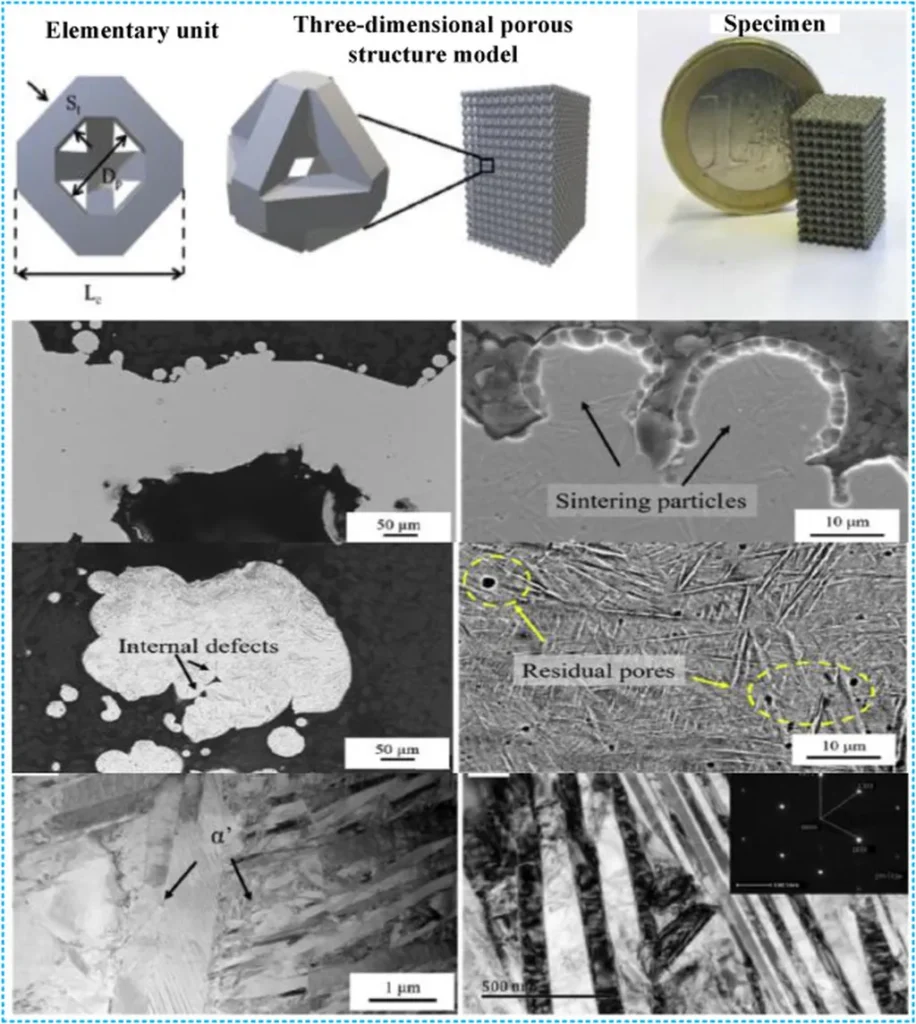

The research involved comprehensive characterization techniques, including Scanning Electron Microscopy (SEM), Energy Dispersive x-ray Spectroscopy (EDS), x-ray Diffraction (XRD), nanoindentation, and electrochemical testing. These methods confirmed that the proposed strategy leads to grain rearrangement, reduced porosity, and the formation of a denser passivation film. The result? A significant improvement in mechanical strength and corrosion resistance.

Under HIP conditions of 525 °C and 100 MPa, pre-drilled specimens exhibited remarkable pore closure. Compared to undrilled specimens, the pre-drilled ones showed enhanced corrosion resistance and mechanical properties. “The improvement in corrosion resistance is particularly noteworthy,” Zhou noted. “This could have profound implications for the energy sector, where materials are often exposed to harsh environments.”

The energy sector stands to benefit immensely from this research. Aluminum alloys are widely used in various energy applications, from power generation to renewable energy technologies. The enhanced corrosion resistance and mechanical properties of ZL205A alloy could lead to longer-lasting, more reliable components. This, in turn, could reduce maintenance costs and improve the overall efficiency of energy systems.

The study’s findings suggest that adopting a reasonable pore structure design before HIP can significantly improve both densification efficiency and service performance of aluminum alloy components. This could pave the way for new manufacturing techniques that optimize material properties for specific applications.

As the energy sector continues to evolve, the demand for high-performance materials will only grow. Zhou’s research offers a promising path forward, demonstrating how innovative approaches to material processing can yield significant benefits. “This is just the beginning,” Zhou said. “We are excited to explore further applications of this technique in other materials and industries.”

In conclusion, the research published in *Materials Research Express* highlights the potential of pore architecture optimization in enhancing the performance of ZL205A aluminum alloy. This breakthrough could shape future developments in material science, offering new possibilities for the energy sector and beyond. As we continue to push the boundaries of what is possible, the work of researchers like Peng Zhou reminds us that innovation often lies in reimagining the familiar.