In a groundbreaking development poised to revolutionize both the construction and energy sectors, researchers have unveiled a novel 3D printing technique that enables the creation of rubber materials with exceptional properties. This innovation, spearheaded by Xiran Lin from the College of Biotechnology and Pharmaceutical Engineering at Nanjing Tech University in China, promises to facilitate all-weather freshwater harvesting, addressing a critical need in water-scarce regions.

The challenge of 3D printing soft, elastic materials with low glass transition temperatures has long plagued the industry. Traditional methods often require external stimuli or precious metal catalysts to maintain structural integrity during printing, adding complexity and cost. Lin and his team have circumvented these issues by introducing modified lignin, a rigid, abundant biopolymer, into the rubber printing process.

“By incorporating modified lignin, we significantly enhance the viscoelasticity and thixotropy of the rubber ink,” Lin explains. “This allows for stable, self-supported printing without the need for additional curing agents or complex setups.”

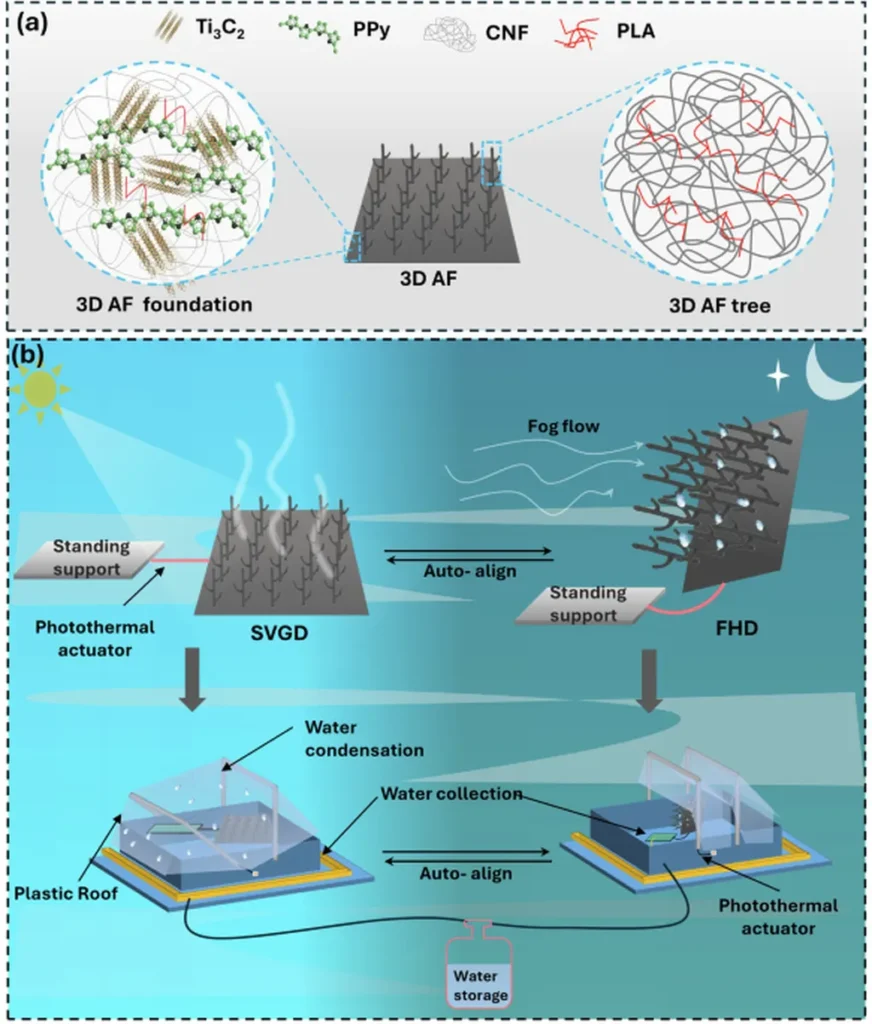

The modified lignin forms covalent bonds and hydrogen bonds with the rubber, increasing its modulus by five orders of magnitude. This enhancement enables the creation of finely structured components with remarkable precision. One of the most compelling applications of this technology is the fabrication of water-harvesting materials designed with a bionic cactus spine structure. These materials demonstrate superior fog-capturing and photothermal evaporation capabilities, making them ideal for freshwater harvesting in diverse climates.

“Our goal is to provide a high-performance solution for all-weather freshwater access,” Lin states. “By combining fog capture and photothermal evaporation, we can achieve an overall water yield of approximately 22 liters per square meter per day.”

The implications for the energy sector are substantial. Efficient water harvesting can support various energy generation processes, from cooling systems in power plants to the production of biofuels. Moreover, the ability to 3D print rubber materials with enhanced properties opens new avenues for developing durable, flexible components for renewable energy infrastructure.

Published in the journal Sustainable Materials (SusMat), this research represents a significant leap forward in materials science and additive manufacturing. As the world grapples with water scarcity and the need for sustainable energy solutions, innovations like this offer a glimmer of hope. The commercial potential is vast, with applications ranging from industrial water harvesting to advanced materials for renewable energy technologies.

“This research not only advances the field of 3D printing but also addresses critical global challenges,” Lin concludes. “We are excited about the potential impact of our work on both the construction and energy sectors.”

As the industry continues to evolve, the integration of modified lignin into 3D printing processes could pave the way for a new era of sustainable, high-performance materials. The future of water harvesting and energy generation looks brighter with each scientific breakthrough, and this research is a testament to the power of innovation in solving real-world problems.