In a groundbreaking study that bridges the gap between nature’s ingenuity and cutting-edge manufacturing, researchers have unveiled a novel approach to designing lightweight yet robust structures inspired by botanical forms. The study, led by Ganesh Chouhan from the Department of Mechanical Engineering at Medi-Caps University in Indore, India, focuses on polygon-based lattice structures that could revolutionize industries requiring high strength-to-weight ratios, particularly in the energy sector.

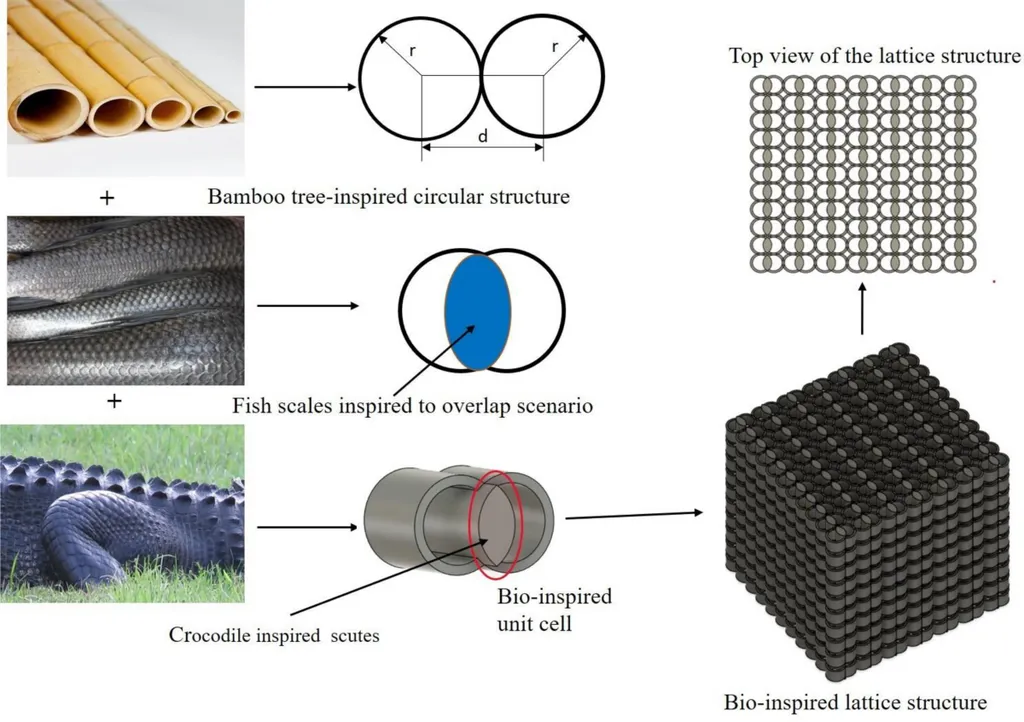

Additive manufacturing, or 3D printing, has long been heralded for its ability to create complex geometries that traditional methods struggle to achieve. Chouhan and his team have harnessed this capability to design and optimize lattice structures inspired by natural forms, which are known for their efficient load distribution and structural connectivity. “Nature has perfected the art of optimizing structures for strength and weight over millions of years,” Chouhan explains. “By mimicking these forms, we can create structures that are not only lighter but also stronger and more efficient.”

The researchers systematically designed square, triangular, and pentagonal unit cells across three porosity levels (50%, 55%, and 60%) to investigate how geometry influences mechanical performance. High-resolution stereolithography (SLA) 3D printing was employed to fabricate these intricate designs, ensuring precision in capturing fine lattice details crucial for accurate mechanical assessment.

To evaluate the mechanical performance of these bio-inspired lattice structures under multidirectional compressive loading, the team employed Finite Element Analysis (FEA) and integrated both computational simulations and experimental testing. The results were striking. The pentagon geometry with 50% porosity lattice exhibited the best compressive performance, achieving a peak strength of 40.1 MPa. This is a remarkable 62% higher than the 50% square lattice and 170% higher than the 60% triangle lattice.

The implications for the energy sector are profound. Lightweight, high-strength materials are crucial for applications ranging from wind turbine blades to offshore platforms, where reducing weight can significantly enhance efficiency and reduce costs. “The potential for these structures in the energy sector is immense,” Chouhan notes. “They could lead to more efficient energy generation and storage solutions, ultimately contributing to a more sustainable future.”

The study also conducted Scanning Electron Microscopy (SEM) analysis to examine fracture mechanisms and microstructural integrity, providing valuable insights into the durability and reliability of these innovative designs. The research was published in the journal “Materials Research Express,” which translates to “Materials Research Express” in English, underscoring its relevance and impact in the field of materials science.

As the world continues to seek sustainable and efficient solutions, the work of Chouhan and his team offers a promising path forward. By looking to nature for inspiration and leveraging the capabilities of additive manufacturing, they have opened new avenues for designing structures that are not only lighter and stronger but also more environmentally friendly. This research could shape future developments in various industries, paving the way for a new era of innovation and sustainability.