In the relentless pursuit of durable and sustainable construction materials, a team of researchers led by Abdullahi Umar Auwal from the Department of Civil Engineering at the Federal University Dutsinma in Nigeria has made a significant breakthrough. Their study, published in the *Journal of Building Materials and Structures* (translated as *Journal of Building Materials and Structures*), explores the potential of Bamboo Leaf Ash (BLA) and Bone Ash (BA) as partial replacements for Ordinary Portland Cement (OPC) in concrete, particularly in environments prone to acid rain and chemically aggressive discharges.

The oil and gas sector, with its exposure to harsh chemical environments, has long struggled with the rapid degradation of concrete infrastructure. Conventional OPC concrete simply doesn’t hold up well in these conditions, leading to frequent and costly repairs. Auwal and his team sought to address this challenge by developing a more resilient and eco-friendly alternative.

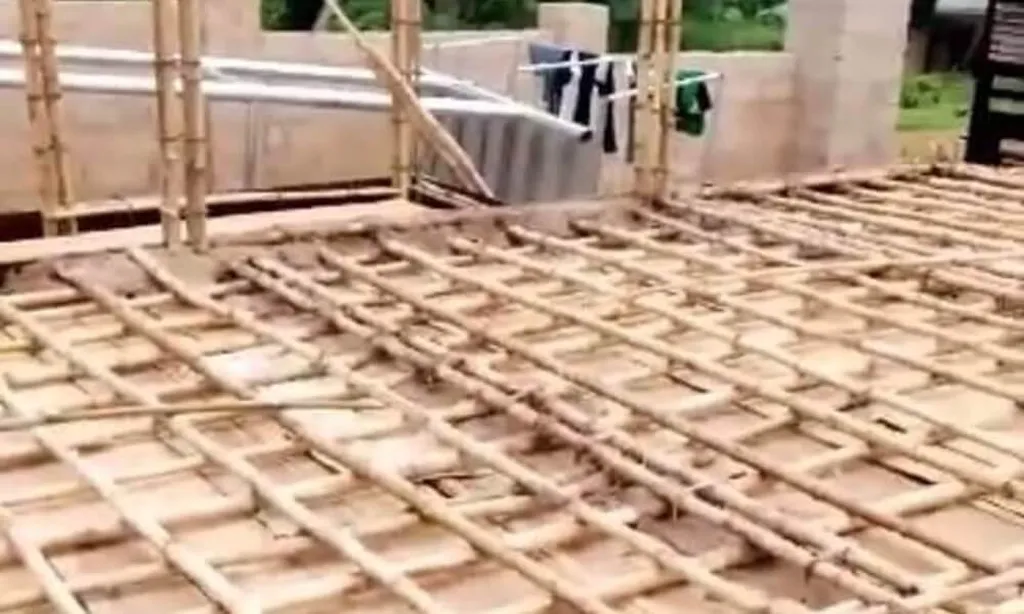

Their solution? A binary pozzolanic system that blends BLA and BA with OPC. By replacing 5–30% of the OPC with these ashes, they created concrete mixes that were not only more resistant to acid attack but also more sustainable. “The idea was to valorize agricultural and animal waste while reducing the demand for cement, a significant source of carbon emissions,” Auwal explained.

The team evaluated various concrete mixes for slump, compressive strength, hardened density, and acid resistance. The standout performer was a mix containing 10% BLA and 5% BA. This blend achieved a 28-day compressive strength of 33.14 N/mm², retained 97.59% of its strength after acid exposure, and exhibited the lowest mass loss at just 2.4%. These results are a game-changer for the energy sector, where infrastructure often faces premature deterioration due to acid rain and chemically aggressive discharges.

The study also employed advanced statistical techniques, including ANOVA, regression modeling, and Pearson correlation analysis, to predict performance trends. The regression models yielded R² values exceeding 0.84, indicating strong predictive reliability. This statistical rigor adds a layer of confidence to the findings, making them not just theoretically sound but practically applicable.

The implications of this research are far-reaching. For the energy sector, the proposed BLA–BA concrete mix offers a durable and sustainable solution for infrastructure in refineries, petrochemical plants, and industrial wastewater systems. The reduced need for cement also aligns with global sustainability goals, making this a win-win for both industry and the environment.

As we look to the future, this research could pave the way for more innovative uses of agro-waste and animal by-products in construction. It challenges us to think beyond traditional materials and explore the untapped potential of waste valorization. In the words of Auwal, “This is just the beginning. The possibilities are vast, and the potential for innovation is immense.”

With the findings published in the *Journal of Building Materials and Structures*, the stage is set for further exploration and adoption of this groundbreaking technology. The energy sector, in particular, stands to benefit greatly from this sustainable and resilient alternative to conventional concrete. As the world grapples with the dual challenges of infrastructure durability and environmental sustainability, this research offers a beacon of hope and a path forward.