In the world of construction, self-compacting concrete (SCC) has long been celebrated for its ability to flow effortlessly into formwork, filling every crevice without the need for vibration. Yet, this very quality can pose significant challenges, particularly when it comes to the pressures exerted on formwork. A recent study, led by Mouhcine Benaicha of the Structure and Materials Laboratory, sheds new light on this issue, offering insights that could revolutionize the way we design and use SCC in the energy sector and beyond.

The study, published in the journal “Advances in Materials Science and Engineering” (which translates to “Advances in Materials Science and Engineering” in English), presents a comprehensive experimental investigation into how key rheological parameters—yield stress and plastic viscosity—and the air content of SCC influence the lateral and vertical pressures exerted on formwork. Benaicha and his team formulated 21 SCC mixtures with systematically varied rheological and fresh-state characteristics, providing a robust dataset for analysis.

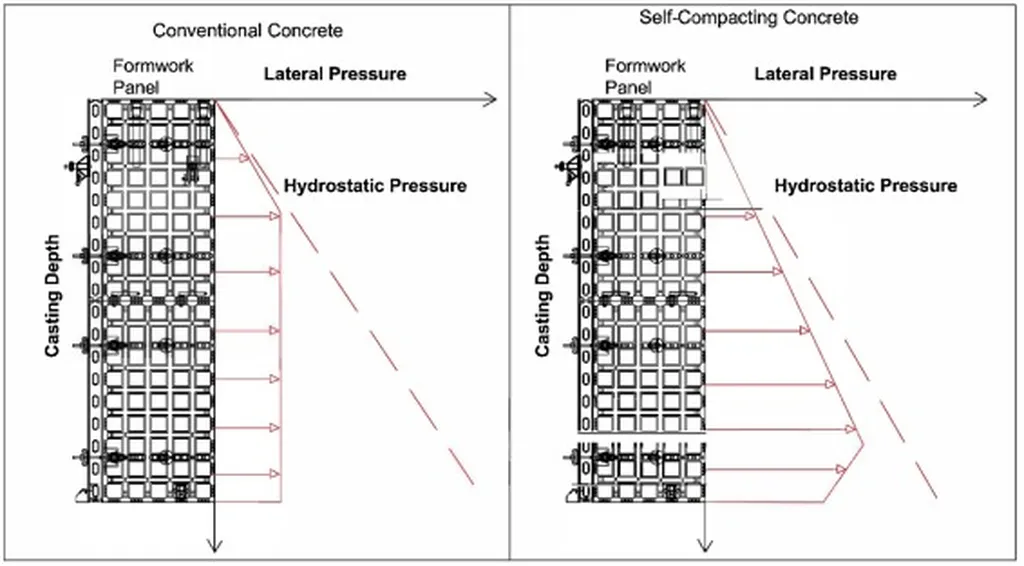

The results were striking. Peak pressures reached 113.92 kPa at midheight and 176.43 kPa at the base, particularly in mixtures with low viscosity, low yield stress, and high air content. These mixtures exhibited near-hydrostatic behavior, meaning they exerted pressures similar to those of a fluid at rest. “This behavior is crucial to understand,” Benaicha explains, “as it directly impacts the design and safety of formwork systems.”

Statistical regression analyses revealed strong inverse correlations between pressure and both yield stress (R2 = 0.89) and plastic viscosity (R2 = 0.91). In other words, as the yield stress and plastic viscosity of the SCC increased, the pressure exerted on the formwork decreased. Conversely, a positive correlation was found between pressure and air content (R2 > 0.95), suggesting that increased air entrainment compromises the structural buildup of SCC.

So, what does this mean for the construction industry, particularly in the energy sector where large-scale, complex structures are common? The findings demonstrate the critical role of rheological and air-related parameters in shaping pressure evolution, offering a basis for mix optimization and safe, efficient formwork design. “By understanding these relationships,” Benaicha notes, “we can tailor SCC mixtures to specific project requirements, enhancing both safety and cost-effectiveness.”

The implications are significant. For instance, in the construction of large-scale energy infrastructure, such as wind turbine foundations or offshore platforms, the ability to predict and control SCC pressures could lead to more efficient formwork designs, reduced material costs, and improved project timelines. Moreover, the insights gained from this research could pave the way for the development of new SCC formulations that balance flowability with pressure management, opening up new possibilities for innovation in the field.

As the construction industry continues to evolve, the need for advanced materials and technologies that enhance efficiency, safety, and sustainability will only grow. This research represents a significant step forward in that direction, providing a foundation for future developments that could reshape the way we build.