In the world of construction machinery, the devil is often in the details—particularly when it comes to the frames that support these powerful machines. A recent study published in the journal *Mining, Construction, Road, and Reclamation Machines* (Гірничі, будівельні, дорожні та меліоративні машини) sheds light on the critical role of support devices in the frames of construction equipment. Led by Ievgenii Gorbatyuk of the Kyiv National University of Construction and Architecture, the research highlights how the choice of support models can significantly impact the structural integrity and performance of these machines.

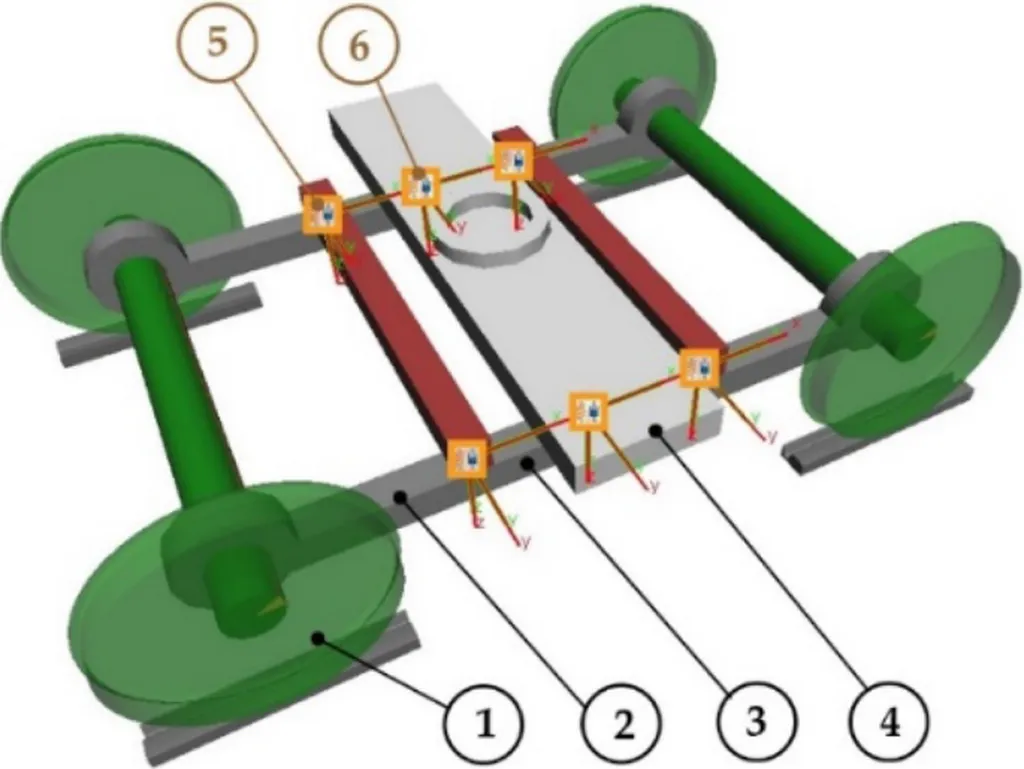

At the heart of the study is the question of how to accurately model the support nodes of metal frames in construction machinery. According to Gorbatyuk, the way these supports are modeled—whether as fixed pivots or as spatially determinate systems—can lead to substantial differences in the calculated loads on the frame. “If you take the same frame with identical applied loads but use different support schemes, you can see that the maximum bending moments in the cross members can differ by approximately 30-35%,” Gorbatyuk explains. This variation isn’t just academic; it has real-world implications for the durability and safety of construction equipment.

The research underscores the need for clear criteria to select the most appropriate calculation model for support devices. “Correctly defining the calculation equivalent for the support nodes of a construction machine’s frame has a significant impact on the accuracy of the data obtained during calculations and simplifies the calculation process itself,” Gorbatyuk notes. This precision is crucial for manufacturers and operators in the construction and energy sectors, where the reliability of heavy machinery directly affects project timelines and budgets.

The findings suggest that future developments in construction machinery design will need to pay closer attention to the modeling of support devices. By refining these models, engineers can ensure that frames are optimized for load distribution, reducing the risk of failures and extending the lifespan of the equipment. For the energy sector, where construction machinery is often deployed in demanding environments, this research could lead to more robust and efficient equipment, ultimately lowering operational costs and improving project outcomes.

As the construction industry continues to evolve, the insights from Gorbatyuk’s research offer a timely reminder of the importance of precision in engineering. By addressing the nuances of support device modeling, the field can move toward more reliable and cost-effective solutions, benefiting both manufacturers and end-users alike.