In the bustling underground network of Shanghai, a groundbreaking study is shedding light on how to better manage and rehabilitate shield tunnels, offering promising insights for the construction and energy sectors. Led by YE Zhenwei from Tongji University’s College of Civil Engineering and the Key Laboratory of Geotechnical and Underground Engineering, the research focuses on the mechanical behaviors of the ground around large deformed shield tunnels rehabilitated by grouting.

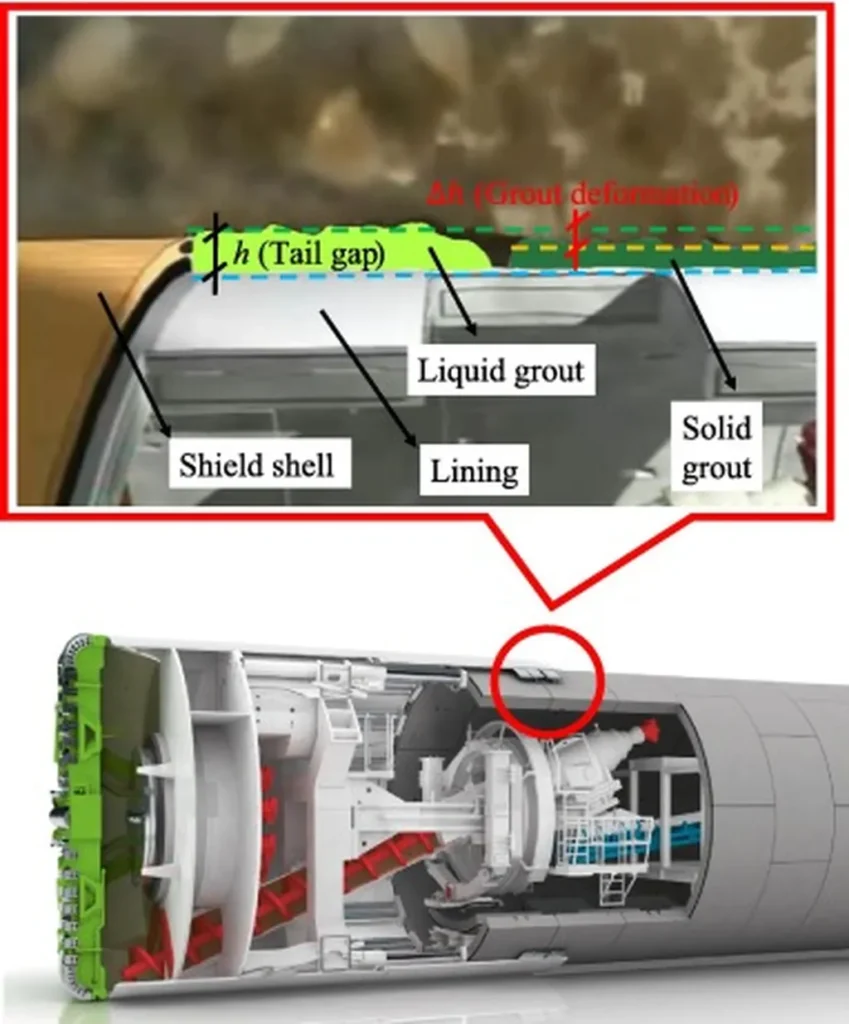

The study, published in *Yantu gongcheng xuebao* (translated to *Chinese Journal of Geotechnical Engineering*), addresses a critical gap in the understanding of stratigraphic mechanical responses during minor-disturbance grouting processes. This technique has become a go-to method for controlling and rehabilitating the transverse deformation of existing shield tunnels, but until now, its impact on the surrounding ground has remained largely unexplored.

“Our goal was to monitor and analyze the variations in earth pressure and pore water pressure during the grouting process,” explained YE Zhenwei. “By installing pressure sensors on both sides of the grouting hole, we were able to gather real-time data that provided a comprehensive picture of the mechanical responses in the ground.”

The research team selected a lining ring as a test site in Shanghai, where they meticulously tracked changes in additional earth pressure, excess pore water pressure, and effective stress near the grouting hole. Their findings revealed intricate details about how the ground responds to grouting, offering valuable data that can inform future engineering practices.

One of the most significant contributions of this study is the correction of slurry distribution coefficients in existing grouting efficiency equations. By aligning these coefficients with the observed variations in earth pressure during grouting, the researchers have provided a new approach to quantitatively characterizing the uncertainty of the grouting body in a two-dimensional plane. This advancement could revolutionize the design of grouting parameters in engineering projects, ensuring more precise and effective rehabilitation of shield tunnels.

The implications of this research extend beyond the immediate scope of tunnel rehabilitation. In the energy sector, where underground infrastructure plays a crucial role, understanding the mechanical behaviors of the ground during grouting processes can lead to more efficient and safer construction practices. This knowledge can also inform the development of new technologies and techniques that minimize disturbance to the surrounding environment, a critical consideration for sustainable energy projects.

As the demand for underground infrastructure continues to grow, the insights gained from this study will be invaluable for engineers and researchers working on large-scale construction projects. By providing a clearer understanding of the mechanical responses in the ground, the research paves the way for more accurate modeling and simulation, ultimately leading to safer and more efficient tunnel rehabilitation.

“This research is a significant step forward in our understanding of grouting processes and their impact on the surrounding ground,” said YE Zhenwei. “We hope that our findings will not only improve current practices but also inspire further innovation in the field of underground engineering.”

As the construction industry continues to evolve, the insights from this study will undoubtedly shape future developments, ensuring that underground infrastructure remains a cornerstone of modern urban development and energy projects.