In the realm of intelligent manufacturing, the ability to detect and interpret acoustic signals with high precision is becoming increasingly vital. A recent study published in the *International Journal of Extreme Manufacturing* (which translates to *International Journal of Extreme Manufacturing*) sheds light on a promising technology that could revolutionize acoustic sensing: triboelectric nanogenerators (TENGs). Led by Xindan Hui from the School of Optoelectronic Science and Intelligent Instrumentation at Xi’an University of Technology in China, the research explores how TENGs can be harnessed to create self-powered acoustic sensors with remarkable sensitivity and cost-effectiveness.

Acoustic sensors are crucial for a wide range of applications, from human-machine interaction to environmental monitoring. Traditional sensors often rely on piezoelectric materials, but these can be limited by their complexity and cost. TENGs, on the other hand, offer a simpler, more flexible, and economical alternative. “The rapid saturation constitutive characteristics of contact-separation mode TENGs provide high sensitivity and an excellent signal-to-noise ratio, making them ideal for detecting micro-scale mechanical signals,” explains Hui.

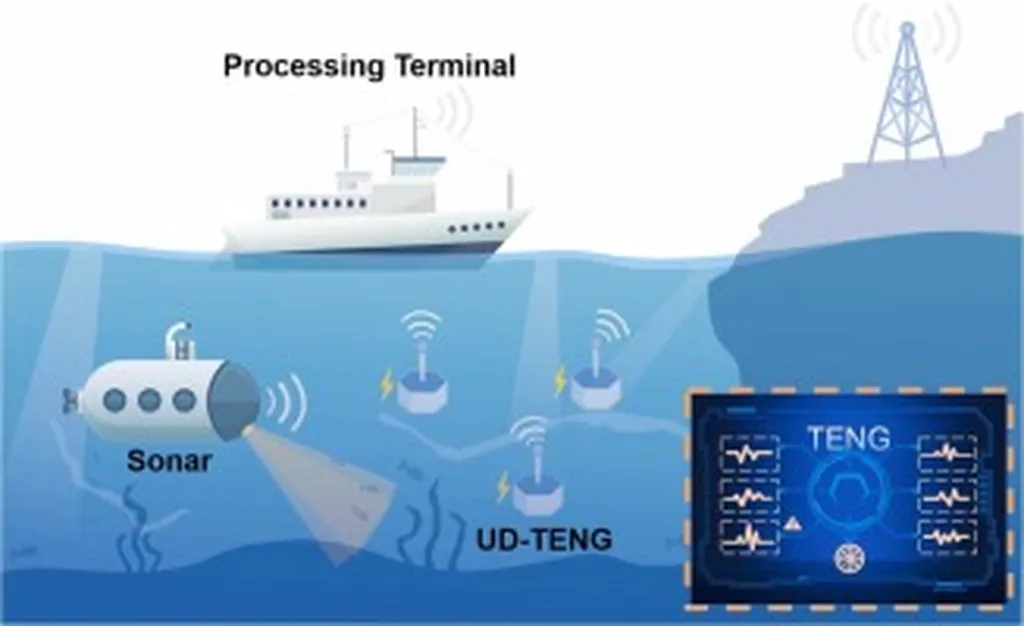

The study provides a comprehensive overview of TENG-based acoustic sensors developed over the past five years, delving into their working principles, fabrication methods, and core structures. One of the key advantages highlighted is the wide range of material options available for TENGs, which allows for greater customization and adaptability in different environments. “This flexibility is particularly beneficial in both air and underwater applications, where traditional sensors may fall short,” notes Hui.

The research also compares TENGs with piezoelectric nanogenerators (PENGs), emphasizing the former’s simplicity and cost-effectiveness. By integrating both displacement and transferred charges, the study proposes a practical figure of merit to evaluate the performance of triboelectric devices, offering a new benchmark for future developments.

The commercial implications of this research are significant, particularly for the energy sector. Self-powered acoustic sensors could enhance monitoring systems in oil and gas operations, renewable energy installations, and industrial machinery, leading to improved efficiency and safety. “As we continue to explore the potential of triboelectric acoustic sensors, we anticipate they will play a pivotal role in advancing intelligent manufacturing technologies,” says Hui.

With continued research and development, TENGs could become a cornerstone of next-generation acoustic sensing, driving innovation across various industries. The study published in the *International Journal of Extreme Manufacturing* not only highlights the current progress but also outlines potential innovation pathways, paving the way for future breakthroughs in this exciting field.