In the bustling urban landscapes where metro stations and deep foundation pits are becoming increasingly common, the challenge of controlling deformation during excavation has been a persistent concern. A recent study published in *Chengshi guidao jiaotong yanjiu* (Urban Rail Transit Research) sheds new light on the effectiveness of servo steel supports, offering insights that could revolutionize construction practices in the energy sector and beyond.

Ru Ye, a lead researcher from the Construction Branch of Ningbo Rail Transit Group Co., Ltd., has been at the forefront of this investigation. The study, conducted using a 1:20 scale model test, compares the performance of servo supports with conventional supports, revealing significant advantages. “Adjusting the servo support axial force during the excavation process yields better performance than adjusting it after excavation completion,” Ye explains. This finding alone could reshape how construction projects approach deformation control, particularly in complex urban environments.

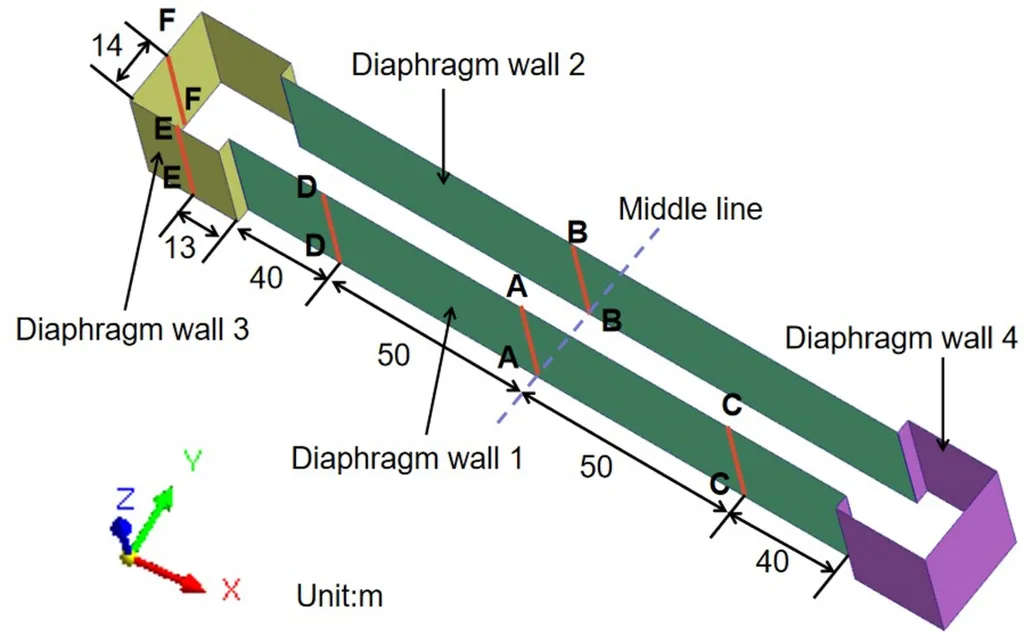

The research delves into the nuances of servo support systems, examining the impact of excavation depth and the combination of support levels on stress and deformation behavior. Ye’s team discovered that adjusting two levels of support provides superior deformation control compared to adjusting a single level. This insight could lead to more efficient and safer excavation practices, ultimately reducing costs and enhancing project timelines.

One of the most intriguing findings is the redistribution of earth pressure behind the wall when servo support axial force is adjusted. “Adjustment at the lowest support level may induce the most significant redistribution of earth pressure,” Ye notes. This discovery highlights the importance of strategic planning in support adjustments, offering a new layer of precision in construction methodologies.

The implications for the energy sector are profound. As urbanization continues to expand, the need for deep foundation pits and metro stations grows. Servo steel supports, with their ability to dynamically adjust to excavation conditions, could become a cornerstone of modern construction practices. The research suggests that by optimizing the timing and levels of support adjustments, construction projects can achieve better deformation control, leading to more stable and secure structures.

Ye’s work not only advances the understanding of servo steel supports but also paves the way for future innovations in the field. As the construction industry continues to evolve, the insights gained from this study will be invaluable in shaping the next generation of support systems. The publication in *Urban Rail Transit Research* underscores the relevance of this research to the broader scientific and engineering communities, offering a foundation for further exploration and development.

In an era where precision and efficiency are paramount, Ye’s research provides a compelling case for the adoption of servo steel supports in urban construction projects. The findings offer a glimpse into a future where deformation control is not just a challenge but a mastered art, ensuring safer, more efficient, and cost-effective construction practices. As the industry moves forward, the lessons learned from this study will undoubtedly play a crucial role in shaping the landscape of urban development.