In the bustling world of smart materials and the Internet of Things (IoT), a groundbreaking development has emerged from the labs of Tohoku University in Japan. Researchers, led by Yuki Sueda from the Department of Frontier Sciences for Advanced Environment, have created a composite material that not only harvests energy from vibrations but also monitors structural health wirelessly—without needing an external power source. This innovation could revolutionize industries where energy efficiency and real-time monitoring are critical, such as aerospace, transportation, and energy infrastructure.

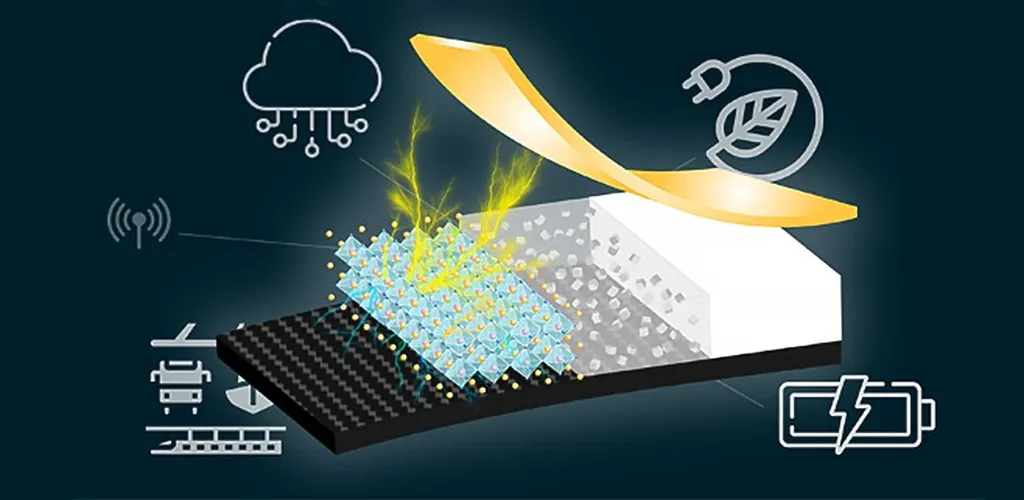

The composite in question is a marriage of carbon fiber-reinforced polymer (CFRP) and potassium sodium niobate-epoxy (KNN-epoxy). CFRP is already a well-known material for its strength and lightweight properties, often used in aircraft and high-performance vehicles. The KNN-epoxy layer adds a twist: it’s piezoelectric, meaning it generates electricity when subjected to mechanical stress, such as vibrations. “By combining these two materials, we’ve created a system that’s both structurally robust and capable of self-powered sensing,” Sueda explains.

In their experiments, the team subjected the composite to bending vibrations, generating a piezoelectric voltage of 13.6 volts at a frequency of 262 Hz. This energy was sufficient to power light-emitting diodes (LEDs) and even wireless IoT modules. But the real magic lies in its ability to detect and report structural damage. By introducing interlaminar cracks of varying lengths, the researchers found a direct correlation between crack size, electrical output, and energy-harvesting efficiency. “The harvested energy’s behavior—how quickly it charges and how often it transmits data—changes with the crack length,” Sueda notes. “This allows us to estimate the structural health state without any external power.”

The implications for industries like aerospace and energy are profound. Imagine aircraft or wind turbines equipped with materials that not only bear loads but also continuously monitor their own integrity and transmit data wirelessly. This could lead to predictive maintenance, reducing downtime and extending the lifespan of critical infrastructure. “The potential for self-powered, wireless sensing is enormous,” Sueda says. “It could transform how we approach structural health monitoring, making systems more efficient and safer.”

The research, published in the *International Journal of Smart and Nano Materials* (translated from Japanese as “International Journal of Smart and Nano Materials”), opens the door to a future where materials do more than just exist—they actively contribute to the systems they’re part of. As industries increasingly prioritize sustainability and efficiency, innovations like this could become the backbone of next-generation infrastructure. The journey from vibration to information has only just begun.