In the quest for higher quality steel ingots, researchers have long grappled with the persistent challenge of slag entrainment, a phenomenon that can significantly compromise the integrity of the final product. A recent study published in *Teshugang* (translated as “Iron and Steel”) sheds new light on this issue, offering insights that could revolutionize ingot casting processes, particularly in the energy sector where high-quality steel is paramount.

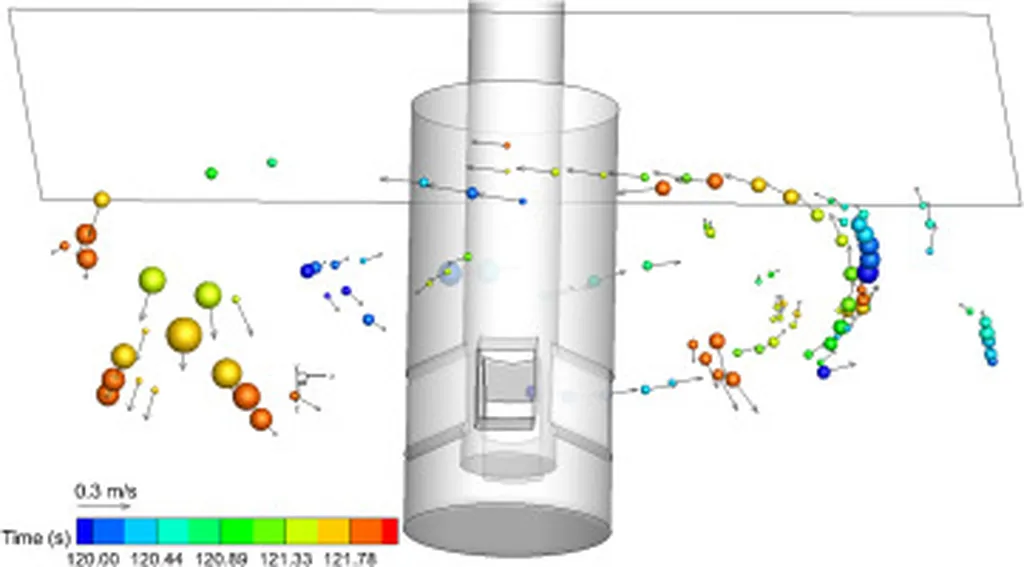

Led by Xu Jichen, a researcher whose affiliation details are not provided, the study focuses on the behavior of molten steel during the ingot casting process. By employing a Volume of Fluid (VOF) multiphase flow model, Xu and his team systematically analyzed the filling flow fields, variations in Weber number, liquid surface fluctuations, and steel-slag interface behavior under different casting speeds. Their findings are nothing short of groundbreaking.

The research reveals that a casting speed of 20 kg/s is the critical threshold at which slag entrainment begins to occur in a 9-ton octagonal ingot. “Below this speed, the flow remains stable, and the steel-slag interface stays intact,” Xu explains. “But when the speed exceeds this threshold, the flow becomes turbulent, and the interface destabilizes, leading to increased slag entrainment.”

The implications of this research are profound, particularly for the energy sector where the quality of steel ingots is crucial. Slag entrainment can lead to defects in the final product, compromising its strength and durability. By understanding the optimal casting speed, manufacturers can enhance the quality of their ingots, ensuring they meet the stringent requirements of the energy industry.

The study also highlights the importance of numerical simulation in understanding complex fluid dynamics. “Our findings demonstrate the power of computational modeling in predicting and mitigating potential issues in the casting process,” Xu notes. This approach not only saves time and resources but also paves the way for more efficient and effective manufacturing processes.

As the energy sector continues to evolve, the demand for high-quality steel ingots is expected to grow. This research provides a crucial stepping stone towards achieving this goal, offering a roadmap for manufacturers to optimize their casting processes and produce ingots of the highest quality.

In the words of Xu Jichen, “This is just the beginning. Our research opens up new avenues for exploring the behavior of molten steel and optimizing the casting process. The future of steel manufacturing is bright, and we are excited to be at the forefront of this exciting journey.”

As the industry continues to push the boundaries of what is possible, this research serves as a reminder of the power of innovation and the importance of understanding the fundamental principles that govern our world. With each new discovery, we move one step closer to a future where high-quality steel ingots are the norm, not the exception.