In a groundbreaking development poised to reshape the fastener industry, researchers have successfully created a high-performance wire rod for Grade 8.8 fasteners using a novel salt bath treatment process. This innovation, detailed in a recent study published in *Teshugang* (translated as “Iron and Steel”), promises to enhance the mechanical properties of fastener steels, offering significant advantages for the energy sector and beyond.

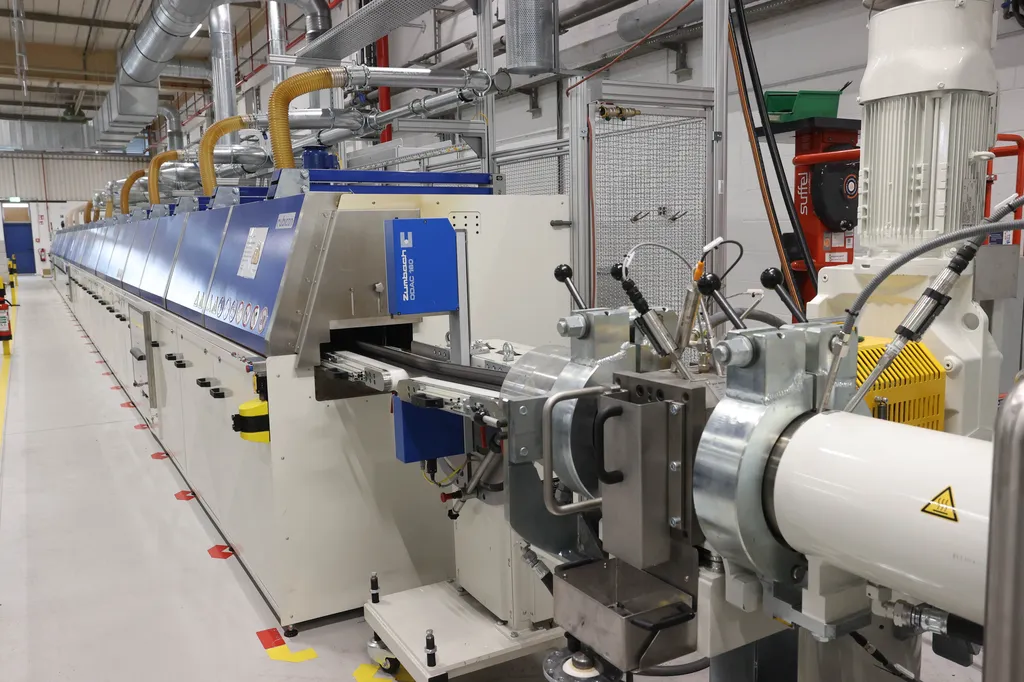

The research, led by Cui Guibo, leverages the first domestically developed industrial-scale online salt bath isothermal heat treatment equipment. By optimizing the composition and employing clean steel smelting technology, the team achieved a predominantly bainitic microstructure in the wire rod. This precise control over the phase transformation microstructure is crucial for achieving the desired mechanical properties.

“Our goal was to develop a wire rod that could meet the stringent requirements of high-strength fasteners without the need for traditional quenching and tempering processes,” said Cui Guibo. “The salt bath treatment allows us to achieve this with remarkable precision and efficiency.”

The QM1020 wire rods, treated at 420°C, demonstrated exceptional performance. The average tensile strength reached 775 MPa, with an average reduction of area of 76%, indicating excellent plasticity and toughness. Notably, the wire rods showed no cracking during 1/6 cold heading tests, a critical factor for fastener applications. Even after drawing with a 29% reduction in cross-sectional area, the steel wires retained high tensile strength and good cold workability, making them suitable for direct cold-heading into flanged bolts that meet Grade 8.8 high-strength fastener standards.

The implications of this research are far-reaching, particularly for the energy sector, where high-strength fasteners are essential for the integrity and safety of structures. The ability to produce these fasteners more efficiently and with superior mechanical properties could lead to significant cost savings and improved performance in critical applications.

“This innovation not only enhances the quality of fasteners but also streamlines the production process,” said Cui Guibo. “It’s a win-win for both manufacturers and end-users.”

The development of the QM1020 salt bath-treated wire rod represents a significant advancement in the field of non-quenched and tempered fastener steels. As the energy sector continues to demand higher performance and reliability from its components, this research could pave the way for future developments in materials science and manufacturing processes.

With the publication of this study in *Teshugang*, the research community now has a robust framework to build upon, potentially leading to further innovations in the production of high-strength fasteners. The collaboration between composition optimization, clean steel smelting, and controlled rolling processes showcases the power of interdisciplinary research in driving technological progress.

As the industry looks to the future, the QM1020 wire rod stands as a testament to the potential of innovative heat treatment methods in enhancing the performance of critical components. This breakthrough could very well set a new standard for fastener manufacturing, benefiting a wide range of industries and applications.