In a significant breakthrough for aluminum alloy research, scientists have discovered a method to substantially enhance the high-temperature strength of these materials, potentially revolutionizing their use in energy-intensive industries. The study, led by Xiaoyu Huang from the International Joint Laboratory for Light Alloys at Chongqing University in China, focuses on the addition of scandium (Sc) to an aluminum-copper-manganese (Al-Cu-Mn) alloy, demonstrating remarkable improvements in thermal stability and mechanical performance.

Aluminum alloys are widely used in various industries due to their lightweight and excellent mechanical properties. However, their strength tends to decrease significantly at elevated temperatures, limiting their applications in high-temperature environments such as aerospace, automotive, and energy sectors. This new research, published in the journal *Materials Research Letters* (translated to English as “Materials Research Letters”), offers a promising solution to this longstanding challenge.

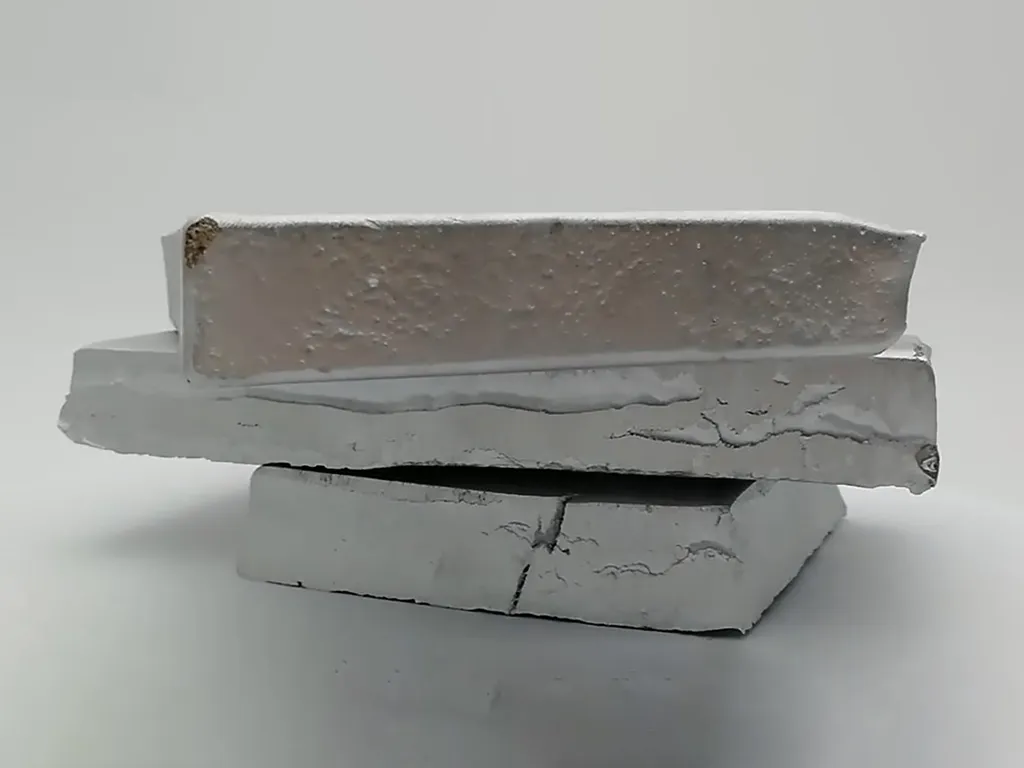

The team investigated the microstructure evolution and mechanical behavior of two alloys: Al-4Cu-0.8Mn and Al-4Cu-0.8Mn-0.2Sc. Both alloys were subjected to 90% cold rolling, a process that significantly deforms the material to enhance its properties. At room temperature, the strength of both alloys was similar. However, at higher temperatures of 250°C and 300°C, the Sc-containing alloy exhibited almost twice the strength of its Sc-free counterpart.

The key to this enhanced performance lies in the addition of scandium, which promotes the formation of θ′ precipitates. These precipitates stabilize the nanoscale microstructure induced by heavy rolling, enabling substantial boundary strengthening at elevated temperatures. This finding challenges the conventional wisdom that boundary strengthening is ineffective for improving the high-temperature strength of aluminum alloys.

“Our research demonstrates that the addition of scandium can significantly improve the thermal stability and high-temperature strength of aluminum alloys,” said Xiaoyu Huang, the lead author of the study. “This discovery opens up new possibilities for the use of aluminum alloys in high-temperature applications, which could have profound implications for industries such as aerospace, automotive, and energy production.”

The potential commercial impacts of this research are vast. In the energy sector, for instance, the development of high-temperature-resistant aluminum alloys could lead to more efficient and durable components for power generation and transmission systems. This could include everything from turbine blades to heat exchangers, where materials must withstand extreme temperatures and mechanical stresses.

Moreover, the enhanced thermal stability of these alloys could extend the lifespan of critical components, reducing maintenance costs and improving overall system reliability. As the world continues to demand more energy-efficient and sustainable solutions, the development of advanced materials like these will be crucial.

The research also highlights the importance of understanding the fundamental mechanisms behind material behavior. By delving into the microstructure evolution and mechanical properties of these alloys, the team has uncovered new insights that could shape future developments in the field.

As Xiaoyu Huang noted, “This study not only provides a practical solution for improving the high-temperature strength of aluminum alloys but also advances our fundamental understanding of the role of scandium in stabilizing nanoscale microstructures. This knowledge can guide the design of next-generation materials with tailored properties for specific applications.”

In conclusion, this groundbreaking research offers a promising path forward for the development of high-performance aluminum alloys. By leveraging the unique properties of scandium, scientists have unlocked new possibilities for enhancing the thermal stability and mechanical strength of these materials. As industries continue to push the boundaries of what is possible, the insights gained from this study will be invaluable in driving innovation and progress in the field of materials science.