In the realm of advanced materials, a breakthrough has emerged that could significantly bolster the energy sector’s pursuit of more robust and efficient components. Researchers, led by Qibin Wang from the School of Materials Science and Engineering at Taizhou University in China, have developed a novel method to enhance the toughness of Nb-Si-based alloys, a material of great interest for high-temperature applications.

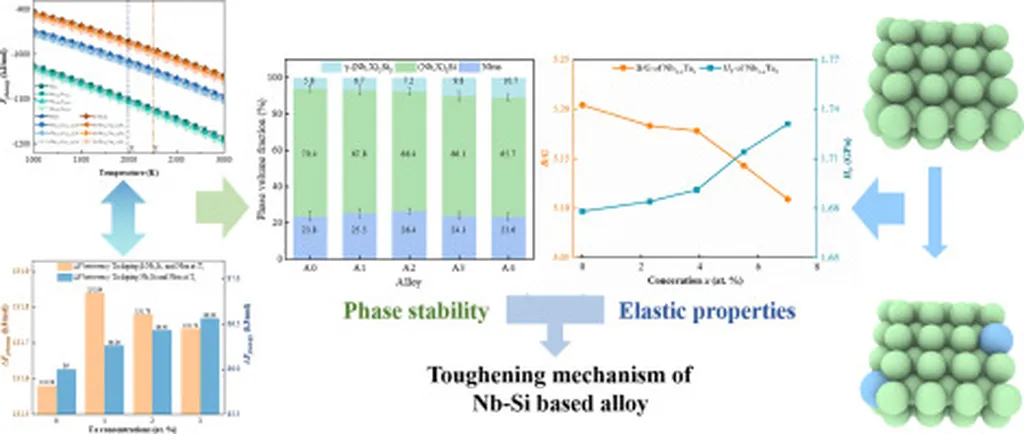

The study, published in the journal *Materials Research Letters* (translated from Chinese as “Materials Research Letters”), focuses on the dual-phase nanoprecipitation within these alloys. By employing a combination of quenching and aging treatments, the team successfully precipitated nanoscale rod-shaped Cr2Nb and granular γ-Nb5Si3 particles. These nanoparticles are meticulously dispersed within the alloy matrix, creating a composite material with remarkable properties.

“The orientation relationship between the precipitates and the Nbss matrix is crucial,” explains Wang. “We found specific crystallographic alignments that significantly improve the material’s toughness.” The precise control of these nanoparticles’ distribution and orientation led to a 51% increase in toughness, reaching an impressive 16.78 MPa·m1/2.

This advancement is not merely academic; it holds substantial commercial implications. Nb-Si-based alloys are already considered for high-temperature applications in the energy sector, such as turbine blades and other critical components. The enhanced toughness achieved through this nanoprecipitation method could extend the lifespan and improve the performance of these components, leading to more efficient and reliable energy systems.

The research provides a theoretical basis and practical approach for regulating nano-reinforcements to improve the properties of composites. This could pave the way for developing next-generation materials tailored for extreme environments, benefiting not only the energy sector but also aerospace, automotive, and other high-performance industries.

As the world continues to demand more efficient and sustainable energy solutions, innovations like this are crucial. The ability to fine-tune the properties of materials at the nanoscale opens up new possibilities for designing components that can withstand the harshest conditions, ultimately driving progress in the energy sector and beyond.

“This research is a significant step forward in the field of materials science,” says Wang. “It demonstrates the potential of nanoscale engineering to create materials with exceptional properties, addressing some of the key challenges in the energy sector.”