In the relentless pursuit of efficiency and durability in high-temperature industrial processes, a groundbreaking discovery has emerged from the State Key Laboratory of Advanced Refractories at Wuhan University of Science and Technology. Lead researcher Fanbo Zeng and his team have uncovered a novel nonlinear corrosion phenomenon at the interface of corundum refractory materials and molten slag, a finding that could significantly impact the energy sector.

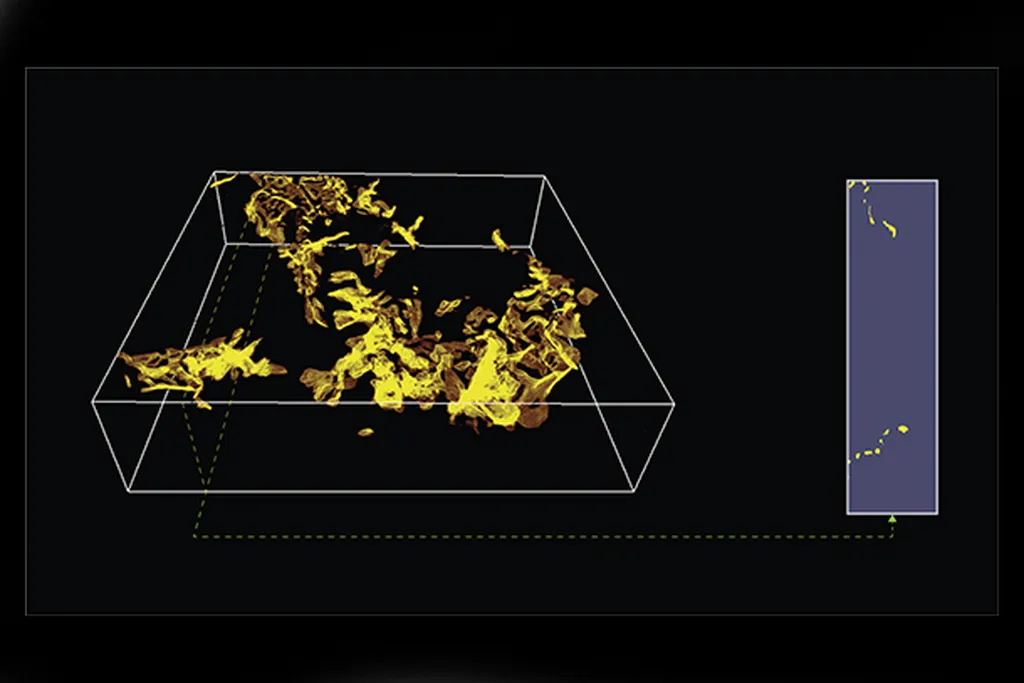

The research, published in *Corrosion Communications* (translated from Chinese as *Corrosion Letters*), reveals that the corrosion process is not as straightforward as previously thought. Instead, it exhibits a periodic pattern reminiscent of Turing patterns, a phenomenon often seen in biological systems but rarely in industrial contexts. This pattern arises from auto-catalytic reactions involving free radicals Ca·+ and O2·-, which diffuse at different rates, creating an unstable distribution of products at each reaction site.

“Initially, we were puzzled by the irregular corrosion patterns we observed,” Zeng explained. “But as we delved deeper, we realized that these patterns were not random but followed a specific dynamic, driven by the interplay of these free radicals.”

The implications of this discovery are substantial for the energy sector, particularly in industries that rely on high-temperature processes such as steelmaking, cement production, and waste incineration. The nonlinear corrosion behavior can lead to unpredictable and accelerated degradation of refractory materials, resulting in costly downtime and maintenance.

However, the research also offers a promising solution. Zeng and his team found that the interfacial auto-catalytic reaction could be inhibited by the radical quenching effect of the Ce3+/Ce4+ redox couple. By modifying the surface of corundum refractory with this redox couple, they were able to completely suppress the formation of the Turing pattern, effectively mitigating the nonlinear corrosion.

“This finding opens up new avenues for developing more resilient refractory materials,” Zeng noted. “By understanding and controlling these radical reactions, we can enhance the longevity and performance of refractories in high-temperature environments.”

The commercial impact of this research could be profound. Industries could see significant cost savings from reduced maintenance and extended equipment lifespan. Moreover, the enhanced durability of refractory materials could contribute to more efficient and sustainable industrial processes, aligning with global efforts to reduce energy consumption and environmental impact.

As the energy sector continues to evolve, the need for advanced materials that can withstand extreme conditions becomes ever more critical. This research not only sheds light on the complex corrosion mechanisms at play but also provides a practical strategy for mitigating these effects. The insights gained from this study could shape the future of refractory technology, driving innovation and efficiency in high-temperature industrial applications.

In the words of Zeng, “This is just the beginning. We are excited about the potential of this research and look forward to seeing how it can be applied in real-world industrial settings.”