In a groundbreaking development that bridges the gap between additive manufacturing and biomedical applications, researchers have unveiled a novel approach to respiratory monitoring using bioinspired sensors. The study, led by Vincenzo Saroli from the Department of Engineering at Università Campus Bio-Medico di Roma, introduces a new way to fabricate and utilize sensors for tracking respiratory rates, with potential implications for various industries, including energy and healthcare.

The research, published in the journal Smart Materials and Structures (translated from ‘SmartMat’), focuses on the fabrication of resistive sensors using fused deposition modeling (FDM), a type of 3D printing technology. The sensors are made from thermoplastic polyurethane (TPU) filled with carbon black (CB), a conductive filler that enhances the material’s sensitivity to temperature and humidity changes.

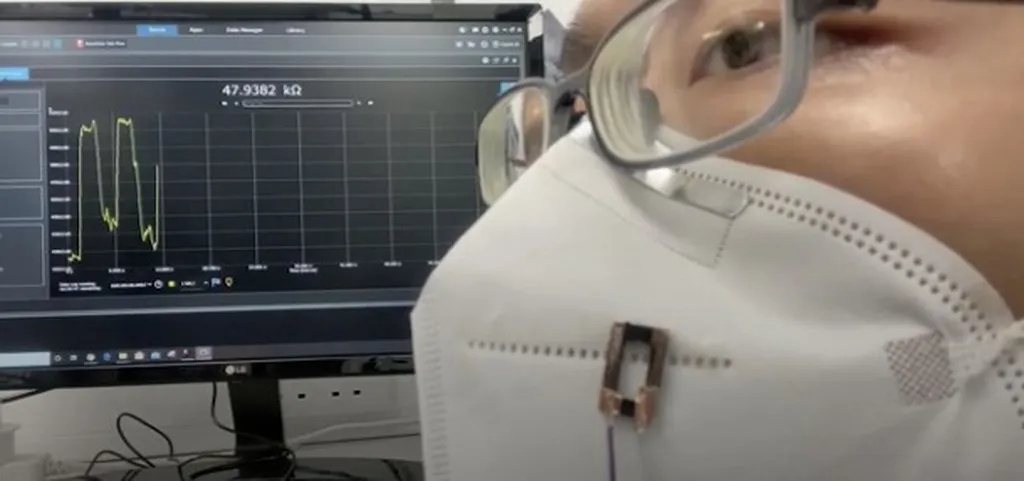

Saroli and his team explored three bioinspired geometries—spider (SP), honeycomb (HC), and flap (FL)—each fabricated with varying thicknesses. The sensors demonstrated a synergistic response to temperature and relative humidity, with resistance increasing as both parameters rose. This behavior is crucial for applications in respiratory monitoring, where the temperature difference between inhaled and exhaled air can be used to estimate respiratory rate.

“The sensors exhibit a parabolic response to temperature variations, with resistance changes up to 125%,” Saroli explained. “This high sensitivity, combined with rapid response times ranging from 15 to 23 seconds and minimal hysteresis, makes them highly suitable for real-time monitoring.”

One of the most significant findings of the study is the influence of sensor geometry and thickness on metrological performance. The honeycomb (HC) geometry, in particular, showed the highest temperature sensitivity, which could be leveraged to optimize sensor design for specific applications.

The potential commercial impacts of this research are vast. In the energy sector, for instance, these sensors could be integrated into wearable devices for workers in high-temperature environments, ensuring their safety by continuously monitoring respiratory rates and environmental conditions. Additionally, the technology could be adapted for use in smart buildings, where monitoring indoor air quality and occupant health could lead to more energy-efficient and sustainable designs.

Saroli’s work not only advances the field of additive manufacturing but also opens up new avenues for the integration of smart materials into everyday applications. As the demand for personalized and efficient healthcare solutions grows, the development of bioinspired sensors fabricated via FDM could play a pivotal role in shaping the future of respiratory monitoring and beyond.

“This research demonstrates the potential of additive manufacturing in creating innovative solutions for healthcare and beyond,” Saroli said. “By leveraging the unique properties of conductive thermoplastic composites, we can develop sensors that are not only highly sensitive but also cost-effective and easy to produce.”

As the world continues to embrace the Internet of Things (IoT) and smart technologies, the integration of such sensors into commercial products could revolutionize the way we monitor and interact with our environment. The study published in Smart Materials and Structures serves as a testament to the power of interdisciplinary research and the endless possibilities that lie at the intersection of engineering and biology.