In a groundbreaking development poised to revolutionize the energy sector, researchers have unveiled a rapid, scalable method for synthesizing covalent organic frameworks (COFs), potentially unlocking their vast potential for real-world applications. The study, published in *Nature Chemical Engineering*, introduces a solid-phase hot-pressing (HP) technique that dramatically accelerates the production of highly crystalline COF platelets, all while eliminating the need for toxic solvents.

Covalent organic frameworks have long been celebrated for their exceptional porosity and tunable structures, making them ideal candidates for gas storage, catalysis, and even atmospheric water harvesting. However, their practical deployment has been stymied by complex synthesis protocols and poor processability. “Traditional methods for synthesizing COFs are often time-consuming and involve hazardous solvents, which limits their scalability and practical use,” explains Qianfeng Gu, lead author of the study and a researcher at the Department of Materials Science and Engineering at City University of Hong Kong.

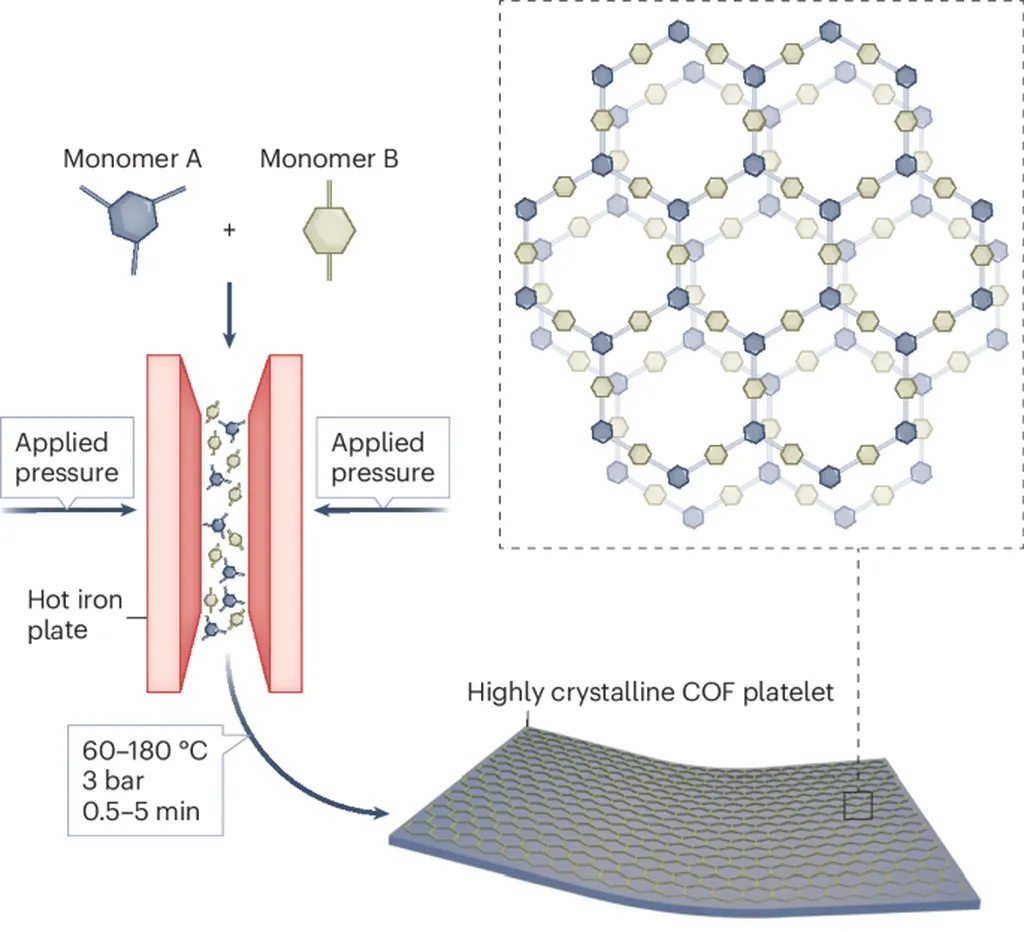

The new hot-pressing method developed by Gu and his team addresses these challenges head-on. By applying heat and pressure to solid-phase precursors, the researchers can produce COF platelets in a matter of minutes. “This approach not only preserves the crystallinity and porosity of the COFs but also allows us to fabricate mechanically robust monoliths, which are crucial for industrial applications,” Gu says.

The implications for the energy sector are profound. COFs have shown promise in applications such as gas separation, energy storage, and catalysis, where their high surface area and tunable chemistry can offer significant advantages over traditional materials. The ability to rapidly and scalably produce COFs could accelerate the development of next-generation energy technologies, from more efficient catalysts for fuel cells to advanced materials for carbon capture and storage.

The study, highlighted in *SmartMat* (translated to English as “Smart Materials”), underscores the potential of this innovative synthesis method to bridge the gap between laboratory research and industrial application. “This breakthrough could pave the way for the widespread adoption of COFs in various energy-related technologies, ultimately contributing to a more sustainable and efficient energy future,” Gu adds.

As researchers continue to explore the capabilities of COFs, the hot-pressing method offers a promising pathway to overcome long-standing barriers to their practical use. The energy sector, in particular, stands to benefit from this advancement, as the rapid and scalable synthesis of COFs could lead to more efficient and cost-effective solutions for energy storage, conversion, and environmental applications. This research not only highlights the ingenuity of the scientific community but also sets the stage for future innovations that could reshape the energy landscape.