In the realm of robotics and prosthetics, the ability to mimic the human sense of touch has long been a coveted goal. A recent breakthrough from Stanford University’s Department of Mechanical Engineering, led by Arielle Berman, brings us one step closer to this reality. Published in the journal npj Flexible Electronics, the research introduces a novel, stretchable, fully capacitive sensing array that could revolutionize the way robots and neuroprosthetics interact with the world.

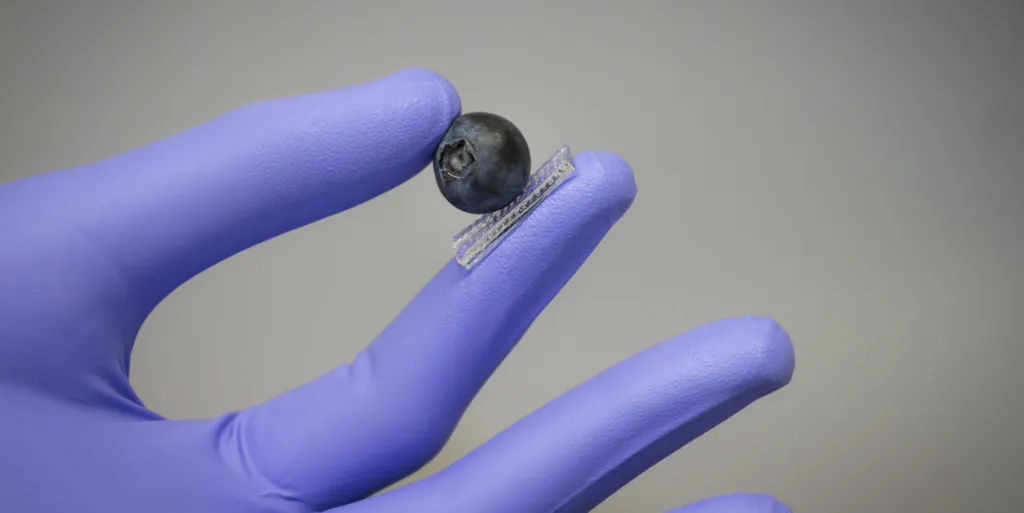

The team’s innovation lies in their unique architecture, which employs rigid islands to create a multimodal sensing array. Unlike existing devices that rely on piezoresistive mechanisms, this new approach uses capacitance to detect changes in pressure and lateral strain. “Our device overcomes the limitations of previous technologies,” Berman explains. “It’s more repeatable, scalable, and offers high-density arrays, which are crucial for advanced applications.”

The implications for the energy sector are substantial. Imagine robotic systems that can intelligently handle delicate tasks, such as inspecting and maintaining solar panels or wind turbines. These robots would need to differentiate between various materials and textures, a feat made possible by this new tactile sensor. “The sensor output trend is maintained even after a five-fold miniaturization of the array sensing area,” Berman adds, highlighting the device’s versatility and potential for integration into compact systems.

The research also demonstrates the device’s real-time material classification capabilities when integrated with a dynamic robotic gripper. This could pave the way for more efficient and accurate quality control processes in energy production and storage systems.

The sensor’s sophisticated feedback mechanism, coupled with its simplicity in data acquisition and analysis, makes it an ideal candidate for training future machine learning algorithms. As the energy sector increasingly turns to automation and AI to optimize operations, this technology could play a pivotal role in enhancing efficiency and safety.

In the broader context, this research opens up new avenues for developing intelligent robots and neuroprosthetics with human-like touch perception. As Berman and her team continue to refine their technology, the future of tactile sensing looks increasingly promising. The journal npj Flexible Electronics, known in English as “npj Flexible Electronics,” serves as a fitting platform for this groundbreaking work, showcasing the potential of flexible electronics in transforming various industries, including energy.

As we look ahead, the integration of such advanced tactile sensors into robotic systems could redefine the boundaries of automation, making tasks safer, more efficient, and more precise. The energy sector, in particular, stands to benefit significantly from these advancements, heralding a new era of intelligent, touch-sensitive robots that can navigate and interact with their environment with unprecedented dexterity.