In the quest for sustainable construction practices, researchers have turned an unlikely waste product into a promising partial replacement for cement. Melaku Mulualem Zewdie, a civil engineer from the Addis Ababa Science and Technology University, has published a study in the journal *Discover Civil Engineering* (translated from Amharic as “Exploring Civil Engineering”) that explores the potential of waste paper pulp ash (WPPA) as a green alternative to Ordinary Portland Cement (OPC).

Zewdie’s research addresses two critical issues in the construction industry: the high carbon emissions associated with cement production and the growing problem of waste disposal. “By utilizing waste paper pulp ash, we can tackle both problems simultaneously,” Zewdie explains. “This approach not only reduces the environmental impact of cement production but also provides a sustainable solution for waste management.”

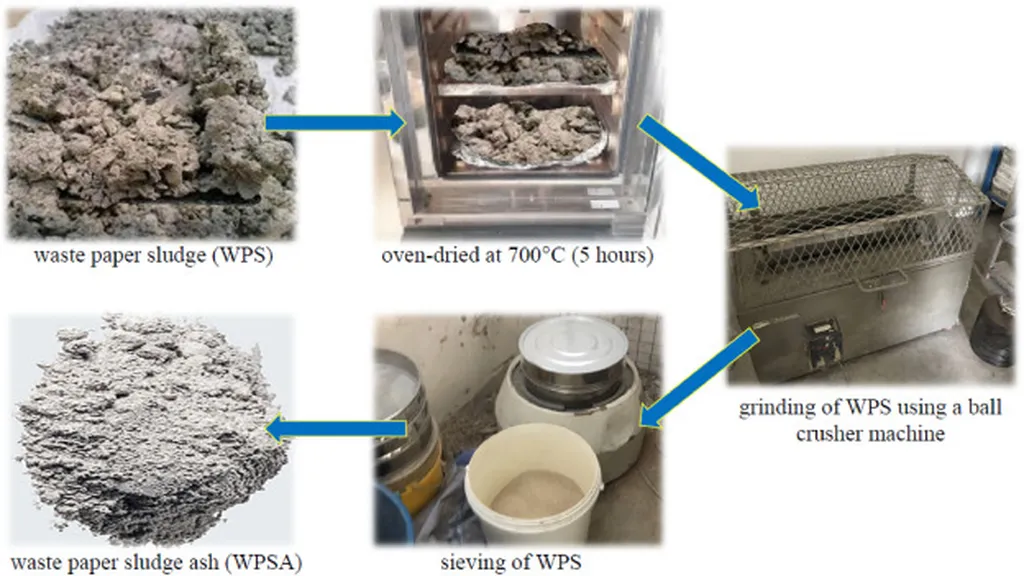

The study involved replacing OPC with WPPA at various levels (0%, 5%, 10%, 15%, and 20% by weight) and evaluating the resulting mortar mixtures for several key properties. The findings were promising. WPPA-blended mortars exhibited higher consistency and longer setting times, which remained within acceptable limits. Water absorption increased slightly with higher WPPA content, but efflorescence remained minimal.

The optimal replacement level was found to be 5%, which produced the highest shear bond strength (0.258 MPa), flexural strength (9.1 MPa), and compressive strength (43.38 MPa) at 28 days. However, strength decreased beyond 10% replacement due to reduced cementitious content.

“This research opens up new possibilities for the construction industry,” says Zewdie. “By incorporating WPPA into cement mortar, we can contribute to resource conservation and reduce the environmental impact of construction projects.”

The commercial implications for the energy sector are significant. As the demand for sustainable construction practices grows, the use of WPPA as a partial cement replacement could become a standard practice. This innovation could lead to cost savings, reduced carbon emissions, and a more sustainable future for the construction industry.

Zewdie’s research, published in *Discover Civil Engineering*, highlights the potential of waste materials in creating sustainable construction solutions. As the industry continues to evolve, the utilization of WPPA and other innovative materials could shape the future of construction, making it more eco-friendly and resource-efficient.

The study’s findings suggest that WPPA can serve as a sustainable and eco-friendly cement substitute, contributing to resource conservation and reducing environmental impact. This research not only addresses the urgent need for sustainable construction practices but also paves the way for future developments in the field. As the construction industry continues to seek innovative solutions, the utilization of waste materials like WPPA could become a cornerstone of sustainable construction.