In the heart of China’s Heilongjiang province, researchers have developed a groundbreaking solution to a persistent challenge in the construction industry: maintaining the structural health of crawler cranes. Yufang Sun, a professor at the College of Mechanical and Electrical Engineering at Heilongjiang Institute of Technology, has led a team that has created a self-powered wireless sensor system for these massive machines, which are critical to large-scale infrastructure projects.

The innovation lies in the system’s ability to harvest energy from the crane’s own vibrations, eliminating the need for battery replacements and complex wiring. “Our approach enables long-term online monitoring of wireless sensor nodes without batteries,” Sun explained. This is a significant advancement, as conventional battery-powered systems have long been plagued by frequent maintenance requirements and limited service life.

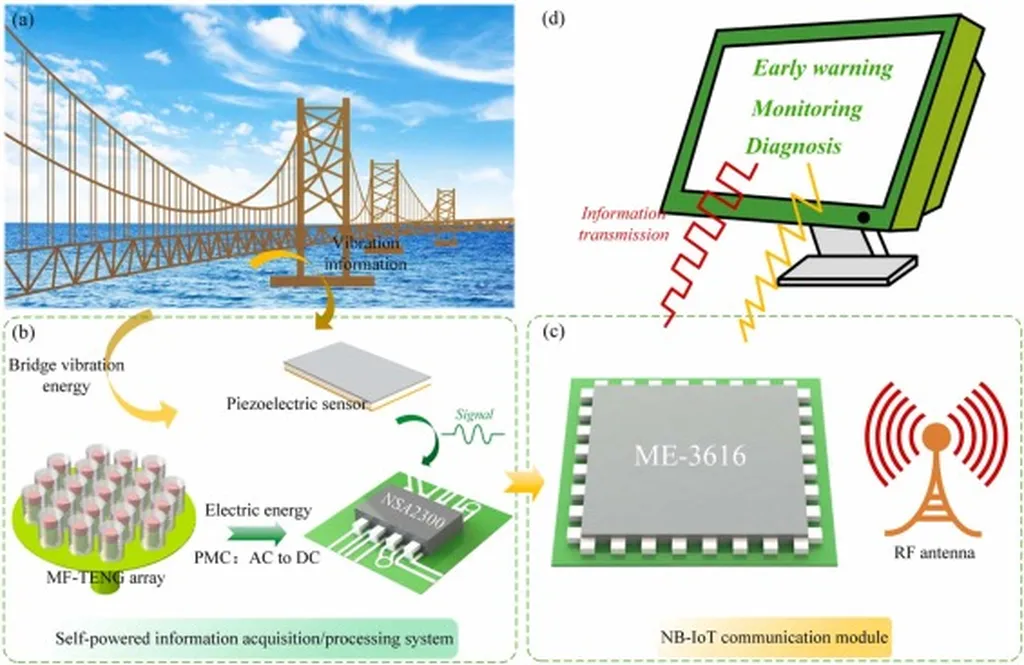

The team’s solution involves a piezoelectric energy harvesting electromechanical coupling model, tailored specifically to the operating conditions of crawler cranes. This model is complemented by a low-power wireless communication protocol that incorporates cluster-head data aggregation and dynamic duty-cycle adjustment. The result is a deep collaboration between energy harvesting, energy storage, and wireless sensing modules.

The impact of this research is substantial. Simulation results showed that the optimized piezoelectric energy harvesting module achieved a peak output power of 8.0 mW at an acceleration of 0.5 g, a 47.5% improvement over the unoptimized configuration. In field deployment experiments involving six sensor nodes, the proposed joint optimization scheme attained an energy utilization rate of 81.5%, extending the average node lifetime to 397.4 hours—65.6% longer than the unoptimized scheme.

This breakthrough could revolutionize the energy sector by providing a feasible technical pathway for upgrading self-powered Internet of Things (IoT) systems in large-scale construction machinery. The “structure-circuit-communication” collaborative optimization framework developed by Sun’s team could be applied to various complex vibration environments, enhancing operational safety and efficiency.

As the construction industry continues to evolve, the demand for reliable, low-maintenance monitoring systems will only grow. Sun’s research, published in the journal *Frontiers in Mechanical Engineering* (translated from Chinese as “Mechanical Engineering Frontiers”), offers a promising solution that could shape the future of structural health monitoring in the energy sector and beyond. The implications of this work extend far beyond the construction site, offering a glimpse into a future where self-powered, wireless sensor networks are the norm, not the exception.