In a groundbreaking development poised to revolutionize the energy sector, researchers have successfully enhanced the properties of aluminum-based nanocomposites through an innovative approach that combines nickel powder and carbon nanotubes (CNTs). This advancement, detailed in a study published in the journal *Materials Research* (translated from Portuguese), could significantly impact the design and efficiency of electrical systems and conductive materials.

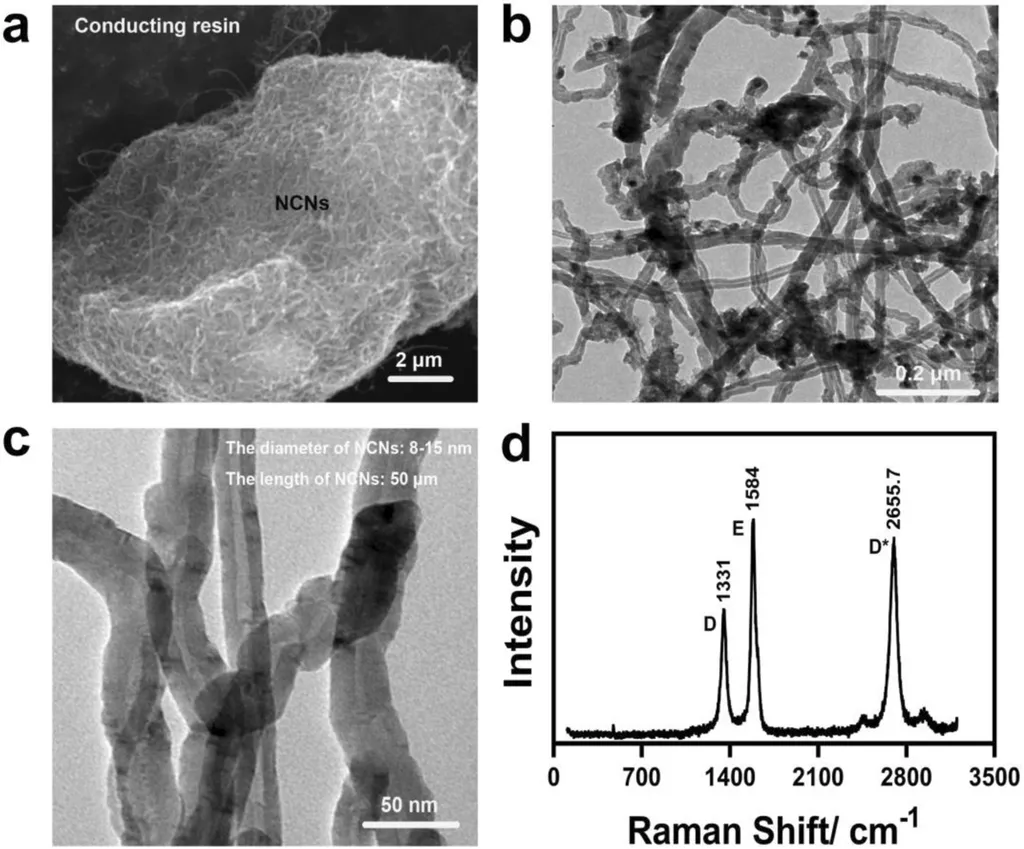

The research, led by Igor Alexsander Barbosa Magno, explores the integration of multi-walled carbon nanotubes (MWCNTs) and nickel powder into aluminum via gravity die casting—a traditional manufacturing process. The challenge of incorporating CNTs into aluminum has long been a hurdle, but Magno and his team have made significant strides by pre-treating the CNTs with isopropyl alcohol and hydrogen peroxide to improve their adhesion to the aluminum matrix.

“Our goal was to refine the grain structure of aluminum and enhance its mechanical and electrical properties,” Magno explains. “By incorporating nickel powder and CNTs, we observed substantial improvements in both electrical conductivity and mechanical strength.”

The results are impressive. The addition of just 0.2 weight percent of nickel and 0.075 weight percent of MWCNTs led to an 18% increase in electrical conductivity and a 7% improvement in mechanical properties compared to commercial electroconductive aluminum. These enhancements were consistent across various compositions, with notable gains in hardness, ultimate tensile strength, and elongation.

However, the study also revealed that the effects are not universally consistent. Occasional reductions in yield strength and elongation highlight the complexity of the interactions between the nanostructured compounds and the aluminum matrix. “The key lies in optimizing the composition and dispersion of the CNTs,” Magno notes. “This ensures that the benefits are maximized while minimizing any potential drawbacks.”

The implications for the energy sector are profound. Enhanced electrical conductivity and mechanical strength in aluminum-based materials could lead to more efficient and durable electrical systems, from power transmission lines to renewable energy infrastructure. The developed nanostructured alloys not only outperform commercial electroconductive aluminum but also open new avenues for innovation in material science.

As the world continues to seek sustainable and high-performance materials, this research offers a promising path forward. By refining traditional manufacturing processes with cutting-edge nanotechnology, Magno and his team have set a new standard for aluminum-based nanocomposites. Their work, published in *Materials Research*, underscores the potential of interdisciplinary collaboration to drive technological advancements and shape the future of the energy sector.