In a groundbreaking study published in *Small Science* (translated as *Small Science*), researchers have unveiled new insights into the behavior of liquid gallium-platinum (GaPt) catalysts, offering promising avenues for advancements in the energy sector. The research, led by Michael S. Moritz from the Friedrich-Alexander-Universität Erlangen-Nürnberg in Germany, focuses on propane dehydrogenation (PDH), a critical industrial process for producing propylene, a key building block for plastics and other chemicals.

The study employs near-ambient pressure X-ray photoelectron spectroscopy (NAPXPS), a sophisticated technique that allows scientists to observe the catalyst’s surface in real-time during the reaction. This operando approach provides unprecedented insights into the dynamic changes occurring at the catalyst’s surface, which are crucial for optimizing catalytic performance.

“By monitoring the active phase during the reaction, we can better understand how the catalyst behaves under real-world conditions,” Moritz explained. “This knowledge is essential for designing more efficient and stable catalysts.”

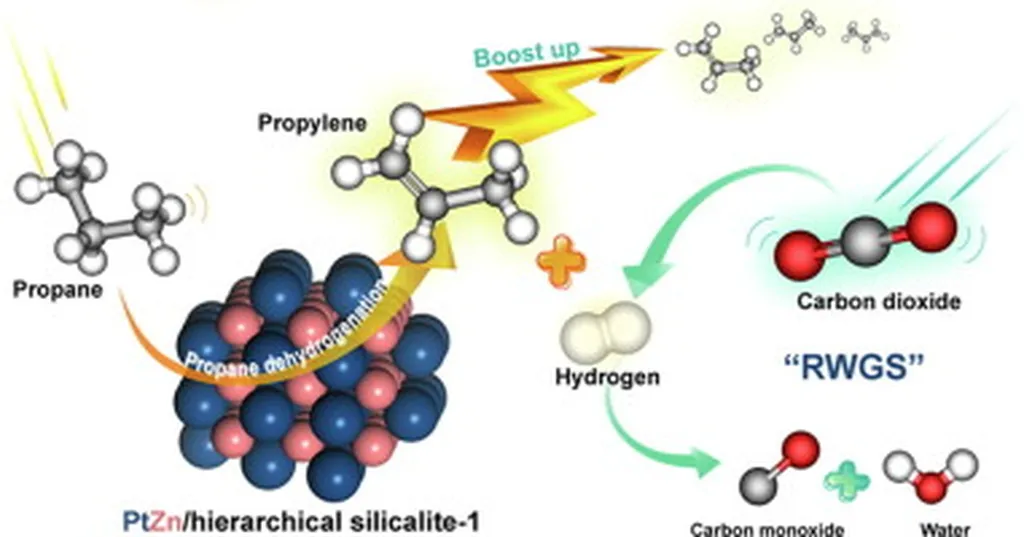

The researchers found that the liquid GaPt catalyst, based on the supported catalytically active liquid metal solutions (SCALMS) concept, exhibits high activity for PDH. However, the presence of oxygen in the feed stream significantly reduces the catalyst’s activity. This finding underscores the importance of maintaining a controlled reaction environment to maximize catalyst performance.

One of the most notable discoveries is the demonstration of a pathway to achieve stable conversion rates immediately after the start of the reaction, bypassing the typical activation period observed in many liquid metal catalysts. “This stability is a significant step forward in developing next-generation catalysts with improved performance,” Moritz noted.

The study also highlights the critical role of oxidic gallium (Ga) in catalytic activity. Understanding this influence provides valuable guidance for optimizing catalyst design, potentially leading to more efficient and cost-effective catalytic processes.

The practical implications of this research are substantial for the energy and chemical industries. PDH is a vital process for producing propylene, and improving catalyst performance can lead to significant energy savings and reduced environmental impact. The insights gained from this study could pave the way for the development of more robust and efficient catalysts, enhancing the overall sustainability of industrial processes.

As the world continues to seek innovative solutions for energy and chemical production, the findings from this research offer a promising direction for future developments. By leveraging advanced techniques like NAPXPS, scientists can continue to unravel the complexities of catalytic systems, driving progress in the field and contributing to a more sustainable future.

The study, published in *Small Science*, represents a significant advancement in the understanding of liquid metal catalysts and their applications in industrial processes. The insights gained from this research are poised to shape the future of catalysis, offering new opportunities for innovation and improvement in the energy sector.