In the relentless pursuit of enhancing semiconductor and display manufacturing, researchers have turned to innovative coating technologies to combat the harsh realities of plasma etching. A recent study, led by Gyutae Park from Yonsei University and LG Display Co., Ltd., has unveiled promising advancements in coating durability that could significantly impact the industry.

The study, published in the journal *Applied Surface Science Advances* (translated as “Advances in Applied Surface Science”), focuses on Y₂O₃–ZrO₂ composite coatings, which have shown remarkable resilience in fluorine-based plasma environments. These coatings are crucial for protecting chamber surfaces from plasma-induced erosion and contamination, ensuring stable processing and high production yields.

Traditional Y₂O₃ coatings have long been the standard, but the increasing complexity of devices and elevated plasma power conditions have pushed the limits of their performance. Park and his team set out to address these challenges by incorporating zirconium oxide (ZrO₂) into the yttrium oxide (Y₂O₃) matrix, creating a composite coating that offers enhanced durability.

“Our goal was to develop a coating that could withstand the harsh conditions of plasma etching while maintaining a clean processing environment,” said Park. “The addition of ZrO₂ to the Y₂O₃ matrix has shown significant improvements in both mechanical and chemical stability.”

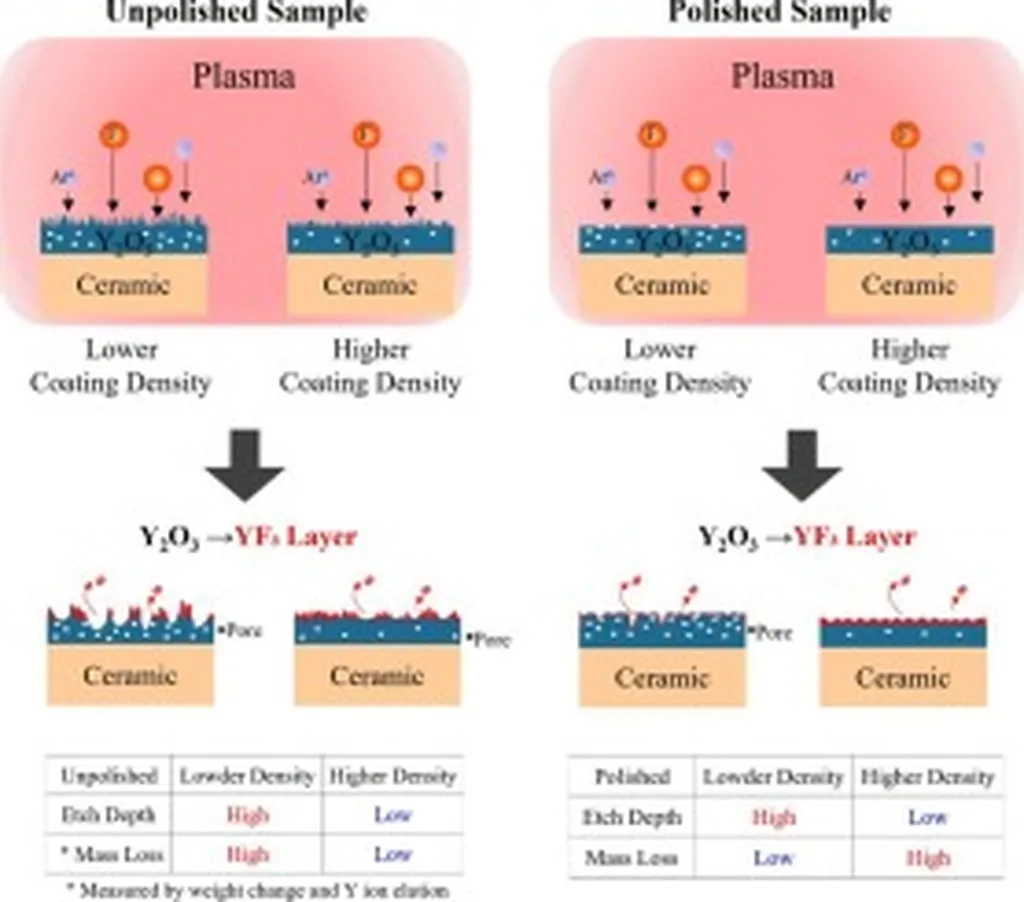

The researchers subjected the Y₂O₃–ZrO₂ composite coatings to a 10-hour plasma etching process in an industrial ICP system using a CF₄/O₂/Ar gas mixture. The results were impressive: the composite coatings exhibited a 13% shallower maximum etch depth compared to conventional Y₂O₃ coatings, along with a 19% reduction in total ionic elution.

This enhanced performance is attributed to the dual stabilizing effects of Zr addition. Mechanically, ZrO₂ reinforces the microstructure, while chemically, it forms stable Zr–F bonds that suppress excessive Y–F formation. “The smaller ionic radius and higher electronegativity of Zr⁴⁺ compared to Y³⁺ enhance its affinity for F⁻ ions, promoting selective fluorination and stabilizing the reaction layer,” explained Park.

The implications of this research are far-reaching. Improved coating durability translates to longer chamber lifetimes and reduced maintenance costs, which are critical factors in the highly competitive semiconductor and display manufacturing sectors. Additionally, the reduced ion elution contributes to a cleaner processing environment, enhancing product quality and yield.

As the industry continues to push the boundaries of device complexity and plasma power, the development of advanced coating technologies like the Y₂O₃–ZrO₂ composite will be essential. This research not only highlights the potential of Zr-modified Y₂O₃ coatings but also paves the way for further innovations in plasma etching technologies.

In the words of Park, “This study represents a significant step forward in our quest for more durable and efficient coatings. We believe that these findings will have a profound impact on the future of semiconductor and display manufacturing.”

With the publication of this research in *Applied Surface Science Advances*, the industry is one step closer to achieving the stability and efficiency required for next-generation manufacturing processes. As the demand for advanced devices continues to grow, the role of innovative coating technologies will be more crucial than ever.