In the ever-evolving world of tunnel construction, a groundbreaking study led by MA Xiaobin from the Key Laboratory of Transportation Tunnel Engineering at Southwest Jiaotong University in Chengdu, China, is set to redefine the way we approach shield tunnel design, particularly in the energy sector. The research, published in *Yantu gongcheng xuebao* (translated to English as *Chinese Journal of Geotechnical Engineering*), delves into the influence of lateral pressure coefficients on the mechanical properties of double-layer lining structures in shield tunnels.

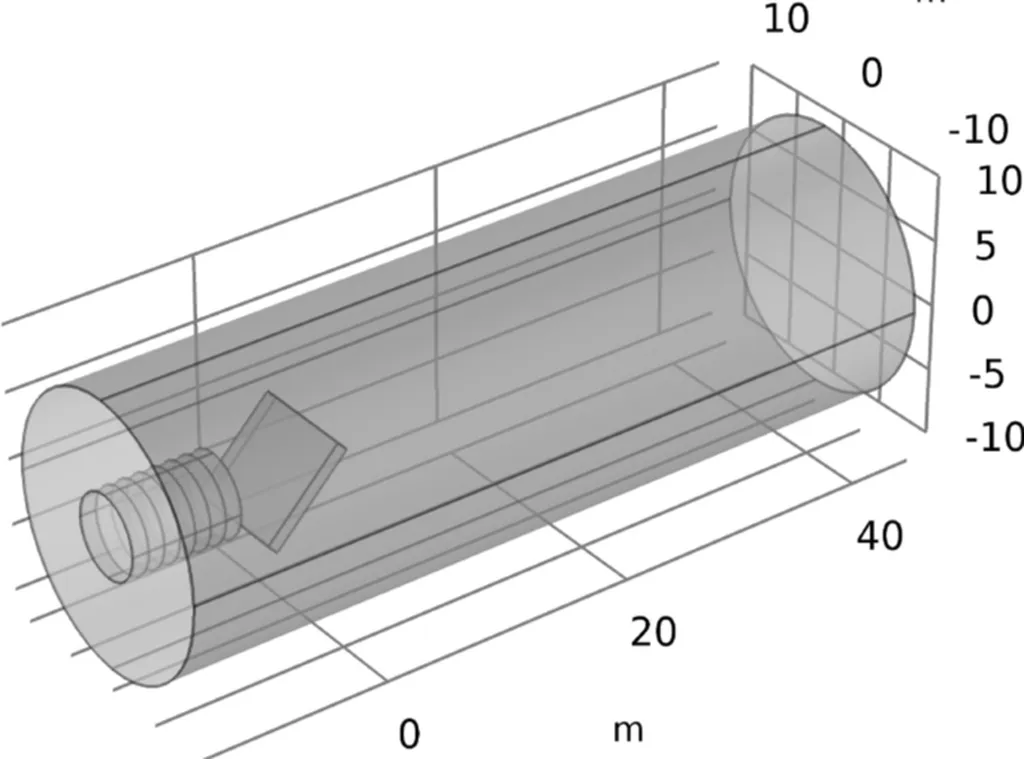

The study, conducted with collaborators WANG Shimin, LIU Chang, and ZHONG Meiyun, focuses on the Shiziyang Tunnel Project along the Guangzhou-Shenzhen High-speed Railway. This project is a critical infrastructure development, and the insights gained from this research could have significant commercial implications for the energy sector, where tunnel construction is often a vital component of infrastructure development.

The researchers conducted similar model tests to analyze the mechanical properties of double-layer lining structures under varying lateral pressure coefficients, ranging from 0.5 to 0.8. Their findings reveal that as the lateral pressure coefficient increases, the double-layer lining structure tends to achieve a more hydrostatic pressure field state. This shift enhances the overall stability and durability of the tunnel.

“Our results show a substantial improvement in the ultimate bearing capacity of the double-layer lining structure as the lateral pressure coefficient increases,” explains MA Xiaobin. “When the coefficient rises from 0.5 to 0.8, the bearing capacity increases by an impressive 66.39%.” This enhancement is crucial for ensuring the safety and longevity of tunnels, particularly in complex and variable soil strata.

The study also highlights a reduction in the maximum radial displacement from 15.17 mm to 9.45 mm, indicating that the secondary lining plays a significant role in improving the bearing capacity of the segmental lining. This finding is particularly relevant for the energy sector, where tunnels often need to withstand high pressures and maintain structural integrity over long periods.

Moreover, the research demonstrates that higher lateral pressure coefficients lead to a decrease in the development of cracks in the segmental lining and reduce the phenomenon of localized falling blocks. This improvement in the reliability of the overall structure is a game-changer for tunnel construction, ensuring that tunnels can withstand the rigors of various environmental conditions.

The implications of this research are far-reaching. For the energy sector, which often relies on tunnel construction for pipelines, transmission lines, and other critical infrastructure, understanding the mechanical properties of double-layer lining structures can lead to more robust and cost-effective designs. This knowledge can also inform better risk management strategies, reducing the likelihood of structural failures and the associated costs.

As the construction scale of shield tunnels continues to grow, the need for innovative solutions that enhance safety and durability becomes ever more pressing. This study provides valuable insights that could shape the future of tunnel construction, ensuring that infrastructure projects are not only technically sound but also economically viable.

In the words of MA Xiaobin, “This research is a step towards optimizing tunnel design and construction practices, particularly in the energy sector. By understanding the mechanical properties of double-layer lining structures, we can build more resilient and efficient tunnels that meet the demands of modern infrastructure development.”

As the industry continues to evolve, the findings from this study will undoubtedly play a pivotal role in shaping the future of tunnel construction, ensuring that projects are completed on time, within budget, and to the highest standards of safety and durability.