In the heart of China’s Yunnan Province, researchers are unraveling the intricate dance between water, rock, and stress, and their findings could have significant implications for the energy sector. Led by Dr. Shen Linfang from the Faculty of Civil Engineering and Mechanics at Kunming University of Science and Technology, a team of scientists has delved into the complex interplay of stress, seepage, and dissolution in three-dimensional rock fractures, shedding light on how these processes influence permeability—a critical factor in oil and gas extraction, geothermal energy, and underground storage.

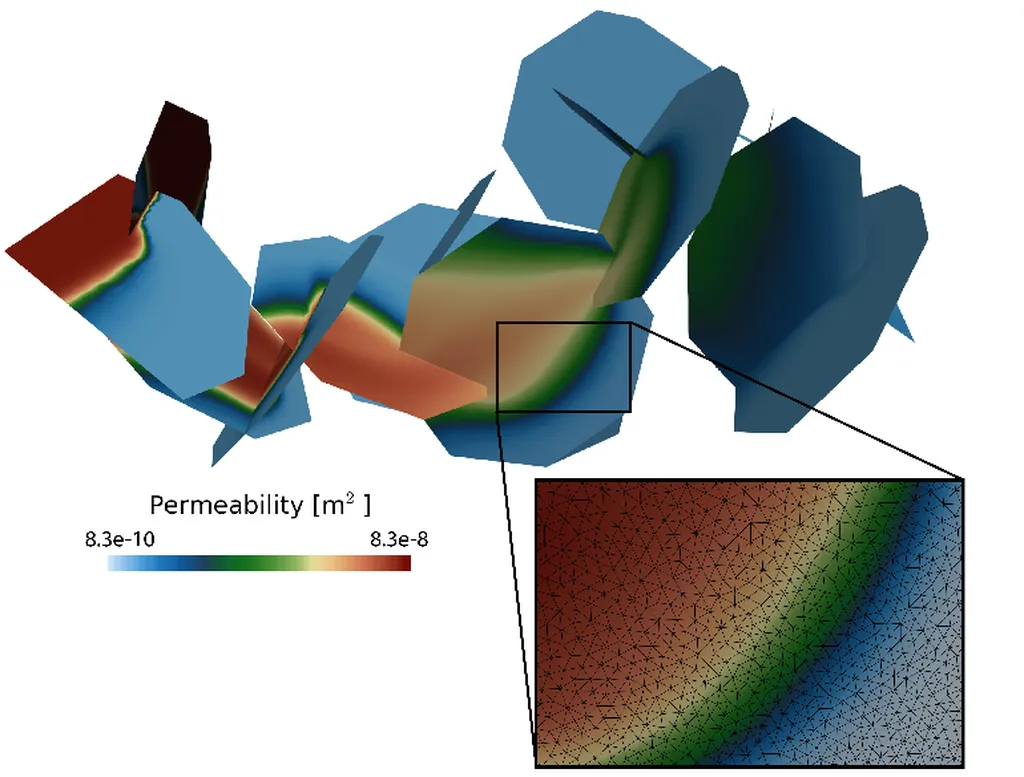

The team’s research, published in *Yantu gongcheng xuebao* (translated as *Rock and Soil Mechanics*), employs the lattice Boltzmann method, a powerful numerical technique, to simulate the evolution of seepage velocity and solute concentration fields in rock fractures. “By understanding how these fields evolve, we can better predict how rock fractures will behave under various conditions,” Dr. Shen explained.

The study reveals that when seepage velocity is low, dissolved ions from the fracture walls can’t be transported quickly enough, leading to a higher concentration and lower dissolution rate at the outlet. This results in a distinctive “bell mouth” shape in the dissolved fracture. “This phenomenon is crucial for understanding how fluids move through rock formations,” said Dr. Lü Qianwen, a co-author of the study.

The researchers also found that increasing normal stress decreases fracture width and slows down solute transport, significantly reducing dissolution at the fracture outlet and limiting permeability development. This insight is particularly relevant for the energy sector, where understanding and controlling permeability is key to efficient resource extraction.

Moreover, the study shows that fracture permeability grows slowly when the wall dissolution rate is low. However, as the dissolution rate increases, the dissolution amount at the outlet lags behind that at the inlet, leading to a rapid growth in fracture permeability once the wall surface at the outlet begins to dissolve significantly.

These findings could revolutionize how energy companies approach reservoir engineering and hydraulic fracturing. By better understanding and predicting permeability changes, companies can optimize their operations, improve resource recovery, and minimize environmental impact.

Dr. Liu Wenlian from the Kunming Prospecting Design Institute of China Nonferrous Metals Industry, another co-author, highlighted the practical applications of the research: “Our findings can provide important theoretical support for the quantitative evaluation of rock fracture permeability under acid corrosion, which is widely used in the oil and gas industry.”

As the energy sector continues to evolve, research like this is more important than ever. By unraveling the complex interactions between water, rock, and stress, scientists are paving the way for more efficient, sustainable, and environmentally friendly energy production. The team’s work serves as a testament to the power of numerical simulation in advancing our understanding of the subsurface world and shaping the future of the energy industry.