In the dense, marshy landscapes where coastal industries often set up shop, engineers face a persistent challenge: deep, soft clay that refuses to settle quickly, even after treatment. This stubborn soil can lead to significant post-construction settlement, triggering a phenomenon known as negative skin friction (NSF) on pile foundations. For the energy sector, where stability is paramount, this can mean costly delays and unexpected maintenance. But a recent study published in *Yantu gongcheng xuebao* (translated as *Rock and Soil Mechanics*) offers new insights that could reshape how we approach pile foundations in these tricky terrains.

Led by LI Bo of the Key Laboratory of Geotechnical Mechanics and Engineering at the Changjiang River Scientific Research Institute, the research team conducted field tests on two prestressed high-strength concrete (PHC) piles in deep soft clay strata. The goal? To understand how NSF affects axial force distribution and bearing performance over time. The findings are nothing short of eye-opening.

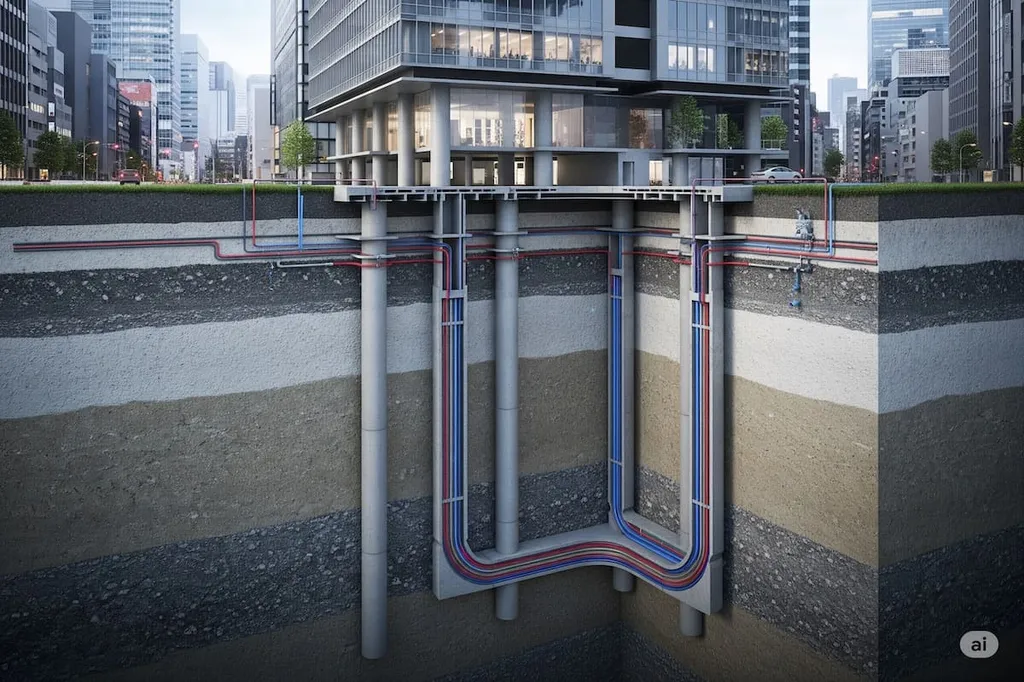

The team monitored the piles under two conditions: without any load on the pile top (Condition I) and with an applied working load (Condition II). Under Condition I, they observed that the axial force at the neutral point—the depth at which the drag load is at its maximum—keeps increasing as the soil settles. For the friction pile, this neutral point migrated downward from 30.00 meters to 44.66 meters, while for the end-bearing pile, it moved from 30.00 meters to 44.66 meters, with drag loads reaching 2160 kN and 3640 kN, respectively.

“What we found was that delaying pile construction until the soil stabilizes post-treatment can reduce drag loads by over 40%,” said LI Bo, lead author of the study. This is a game-changer for industries like oil and gas, where time and cost efficiency are critical. The current design codes, which assume static neutral points, tend to overestimate drag loads, leading to overly conservative—and potentially costly—bearing capacity predictions.

Under Condition II, after 55 days of sustained loading, the team noticed something intriguing: the proportion of the pile-top load increment transmitting below the neutral point significantly attenuated. The upper pile-soil interface even transitioned to a positive friction zone due to pile penetration. This suggests that the behavior of piles in deep soft soil is far more dynamic than previously thought.

So, what does this mean for the future of pile foundations in the energy sector? For one, it means that engineers might need to rethink their timelines. Waiting for soil to stabilize before constructing piles could save significant costs and reduce long-term maintenance. It also means that current design codes may need an update to reflect the more nuanced understanding of neutral point migration and drag load behavior.

As YU Jianfei, co-author from Zhejiang Petrochemical Co. Ltd., put it, “This research provides a solid foundation for optimizing pile design in deep soft soil regions. It’s not just about saving money—it’s about building smarter, more resilient infrastructure.”

The study, published in *Yantu gongcheng xuebao*, offers a fresh perspective on an age-old problem. For the energy sector, where every centimeter of settlement and every kilonewton of drag load matters, these findings could pave the way for more efficient, cost-effective, and stable foundations. And in an industry where time is money, that’s a development worth paying attention to.