In the depths of the Earth, where energy extraction and infrastructure development often meet complex geological challenges, a team of researchers has made a significant stride in understanding how to secure structures in jointed rock masses. Led by SONG Yang from Liaoning Technical University, the team has developed a mechanical model for anchorage resistance that could revolutionize how we approach deep rock engineering, particularly in the energy sector.

The study, published in *Yantu gongcheng xuebao* (translated to *Rock and Soil Mechanics*), focuses on the anchorage mechanism of filling jointed soft rock, a problem that has long puzzled engineers and researchers alike. “The anchorage mechanism of filling jointed soft rock is more complex and not yet clear,” explains SONG Yang, highlighting the need for a robust computational model for anchorage resistance.

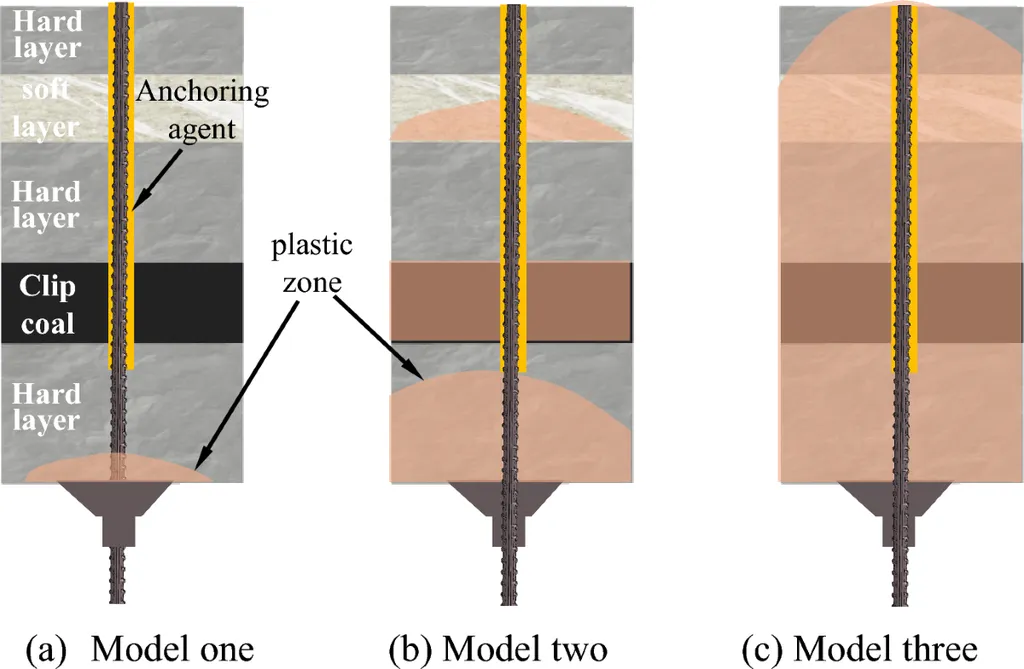

The researchers based their model on the theory of structural mechanics, considering the constraint stress in the extrusion deformation zone of the bolt as a rectangular distribution mode. They modified the value of the constraint stress to a formula expressed by the strength and filling degree of the filling materials. This innovative approach allows for a more accurate prediction of anchorage resistance, which is crucial for the stability of structures in deep rock masses.

The team conducted shear tests on anchored filling jointed rock mass under constant normal stiffness (CNS) boundary conditions to verify their model. The results were promising, showing that the ratio of the length of the shear deformation section of the anchor rod to its diameter is typically between 0.7 and 1.5. As the filling degree increases, the theoretically calculated values of the shear contribution rates of the anchor rod also increase, indicating a significant improvement in anchorage resistance.

“This research provides a new perspective on the anchorage design theory of jointed rock mass,” says SONG Yang. The findings could have substantial commercial impacts for the energy sector, particularly in mining and underground construction, where the stability of structures is paramount. By understanding the distribution characteristics of bolt resistance, engineers can design more effective anchorage systems, reducing the risk of failures and improving the safety and efficiency of operations.

The research also sheds light on the behavior of anchorage systems under large angular displacements. The study found that the shear force initially bears the main resistance behavior, but as the anchorage angle increases, the axial force gradually takes over until the anchorage system fails. This insight could lead to the development of more resilient anchorage systems that can withstand the complex stresses and strains encountered in deep rock engineering.

As the energy sector continues to push the boundaries of exploration and extraction, the need for advanced anchorage technologies becomes increasingly critical. The mechanical model developed by SONG Yang and his team represents a significant step forward in this field, offering a more accurate and reliable method for predicting anchorage resistance. This research not only advances our understanding of jointed rock mass behavior but also paves the way for safer and more efficient energy extraction and infrastructure development.

In the ever-evolving landscape of deep rock engineering, this study serves as a beacon of innovation, guiding the industry towards a future where the challenges of jointed rock masses are met with confidence and precision. As the energy sector continues to grow, the insights gained from this research will be invaluable in shaping the technologies and practices of tomorrow.