In the realm of dam construction, a recent study published in *Yantu gongcheng xuebao* (translated to *Rock and Soil Engineering*) is set to challenge conventional wisdom and potentially reshape how engineers approach the design and stability analysis of submerged toe walls in high concrete face rockfill dams. The research, led by JI Enyue of the Geotechnical Engineering Department at Nanjing Hydraulic Research Institute, alongside colleagues FU Zhongzhi, ZHEN Feng, and XU Ming, delves into the intricate behavior of earth pressure on these critical structures.

Submerged toe walls play a pivotal role in the stability and performance of high dams, but until now, the distribution and variation of earth pressure on these walls during construction and impounding periods have remained somewhat of a mystery. “The traditional theories we’ve been using may not be capturing the full picture,” JI Enyue explains. “Our study aims to provide a clearer understanding of the forces at play.”

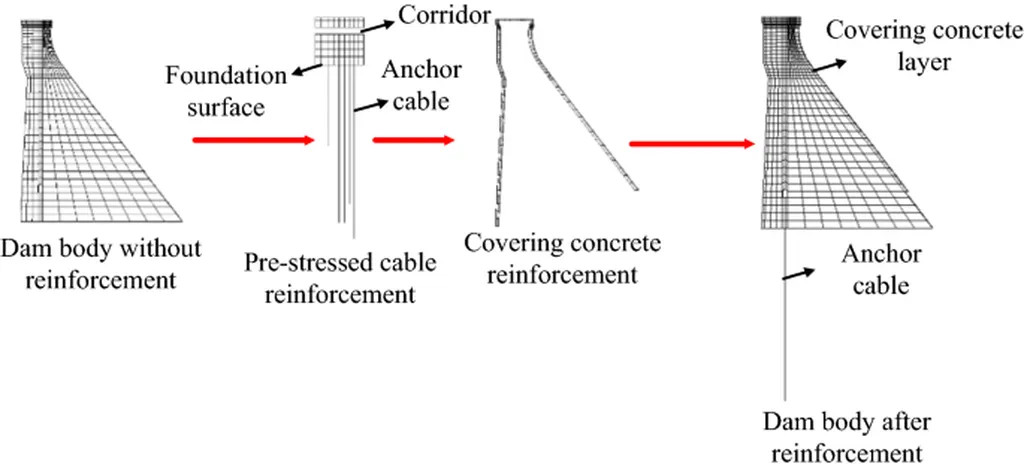

Using a sophisticated 2D plane strain finite element model, the research team simulated the behavior of a concrete face rockfill dam with a 10-meter toe wall. Their findings reveal a complex interplay of forces. After impounding, the normal stress along the upper part of the contact surface decreases gradually, while the lower part experiences a slight increase. The normal stress distribution takes on a parabolic shape, with the peak stress occurring near the center of the interface. This is a significant departure from what traditional earth pressure theories might predict.

The study also highlights the impact of the friction angle of the contact surface on shear stress. As the friction angle increases, so does the shear stress, and the range of the contact surface that reaches the ultimate shear stress gradually decreases. This nuanced understanding of shear behavior is crucial for ensuring the stability of submerged toe walls.

One of the most compelling findings is the behavior of the toe wall during construction. The wall displaces upstream, accompanied by a rapid increase in the normal resultant force. The shear force, on the other hand, initially decreases to zero before rapidly increasing during subsequent construction stages. This dynamic behavior underscores the need for more sophisticated modeling techniques to accurately predict the performance of submerged toe walls.

The earth pressure coefficient (K) obtained from the finite element analysis falls between the maximum active earth pressure coefficient (Ka) and the minimum passive earth pressure coefficient (Kp) from Coulomb’s earth pressure theory. This discrepancy suggests that traditional theories may not be suitable for evaluating the stability and stresses of submerged toe walls. “Our results indicate that there’s a certain error in the earth pressure on the toe wall calculated by traditional methods,” JI Enyue notes. “This could have significant implications for the design and safety assessment of high dams.”

The commercial impacts for the energy sector are substantial. Accurate modeling of earth pressure on submerged toe walls can lead to more efficient and safer dam designs, reducing the risk of failures and the associated costs. It can also inform better maintenance practices and extend the lifespan of existing structures. As the demand for renewable energy continues to grow, the insights from this research become increasingly valuable.

Looking ahead, this study paves the way for further research into the behavior of submerged toe walls under various conditions. It also highlights the importance of advanced modeling techniques in understanding the complex interactions within dam structures. As JI Enyue and his team continue to explore these dynamics, the energy sector can look forward to more robust and reliable designs for high dams.

In the ever-evolving landscape of dam construction, this research serves as a reminder that even well-established theories can be refined and improved. By embracing new methodologies and challenging conventional wisdom, engineers can push the boundaries of what’s possible, ensuring the safety and efficiency of our critical infrastructure.