In the world of dam remediation, the quest for stronger, more durable cement-based grouting materials has taken a significant leap forward. Researchers, led by Xiaoyi Jiang from Zhejiang Guangchuan Engineering Consulting Co., Ltd in Hangzhou, China, have discovered that adding sepiolite fibers to traditional cement grout can dramatically enhance its performance. This breakthrough, published in the journal *Materials Research Express* (which translates to *Materials Research Express* in English), could have profound implications for the energy sector, particularly in the maintenance and repair of earth-rock dams.

The study focused on improving the early strength and flexural strength of cement-based grouting materials used in anti-seepage grouting projects. By incorporating sepiolite fibers, along with fly ash, ultra-fine silica fume, bentonite, and other additives, the team was able to create a composite material with superior properties. “The addition of sepiolite fibers not only improves the mechanical strength but also accelerates the setting time of the grout,” explained Jiang. This means that repairs can be completed faster, reducing downtime and costs.

One of the most striking findings was the significant reduction in the bleeding rate of the slurry under optimal conditions. With the right mix of 5% long fibers, 9.5% silica fume, and 9.5% fly ash, the bleeding rate decreased by 6.6%. The initial and final setting times were also shortened by 29.1% and 33.0%, respectively. “This acceleration in setting time is crucial for large-scale projects where time is of the essence,” noted Jiang.

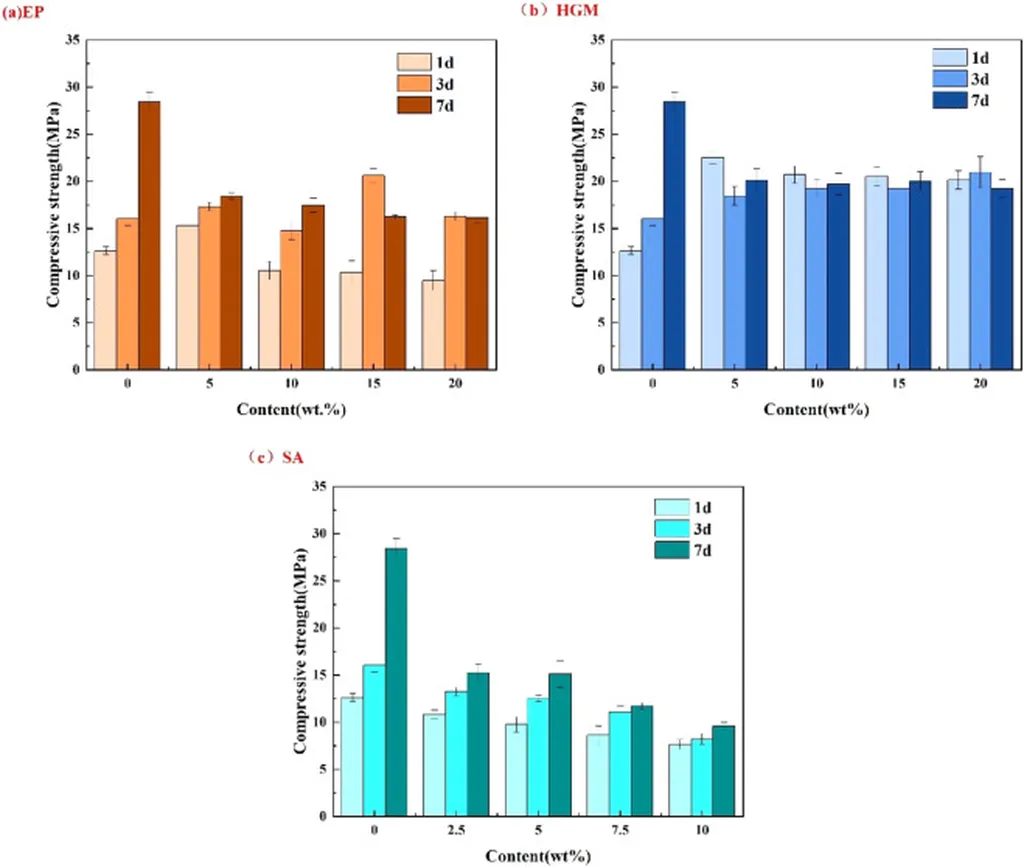

The mechanical properties of the grout were also substantially enhanced. At just three days of age, the flexural strength increased by 146.7% (3.7 MPa) and the compressive strength by 55.3% (19.3 MPa) compared to the reference sample. At 28 days, the improvements were still remarkable, with a 87.8% increase in flexural strength (7.7 MPa) and a 42.6% increase in compressive strength (40.6 MPa).

The study also employed response surface analysis to determine the optimal mix for early strength performance. The best results were achieved with a combination of 4.21% sepiolite fibers, 14.0% silica fume, and 10.19% fly ash. This level of precision in material science is a game-changer for the energy sector, where the integrity of dams and other infrastructure is paramount.

The microstructural analysis revealed that sepiolite fibers play a crucial role in bridging various cement hydration products, accelerating the hydration and bonding process. This fiber-reinforced composite structure effectively prevents the growth of microcracks, significantly enhancing the early strength of the material.

The implications of this research are far-reaching. For the energy sector, which relies heavily on robust infrastructure, the development of stronger, more durable grouting materials can lead to more efficient and cost-effective maintenance and repair projects. “This innovation has the potential to revolutionize the way we approach dam remediation and other large-scale construction projects,” said Jiang.

As the energy sector continues to evolve, the need for advanced materials that can withstand the test of time and environmental stressors becomes increasingly critical. The work of Xiaoyi Jiang and his team, published in *Materials Research Express*, represents a significant step forward in this direction. By leveraging the unique properties of sepiolite fibers, the construction industry can look forward to a future where infrastructure is not only stronger but also more resilient.