In the shadowed depths of tunnels, subways, and mine shafts, a silent sentinel is emerging, poised to revolutionize safety monitoring in underground structures. Researchers from the Geotechnical Engineering Research Institute at Zhejiang University, led by Dr. Hong Chengpeng, have developed a groundbreaking thin-film pressure sensor that promises to enhance the accuracy and reliability of gas explosion monitoring. This innovation could have significant commercial implications for the energy sector, particularly in ensuring the safety of underground energy infrastructure.

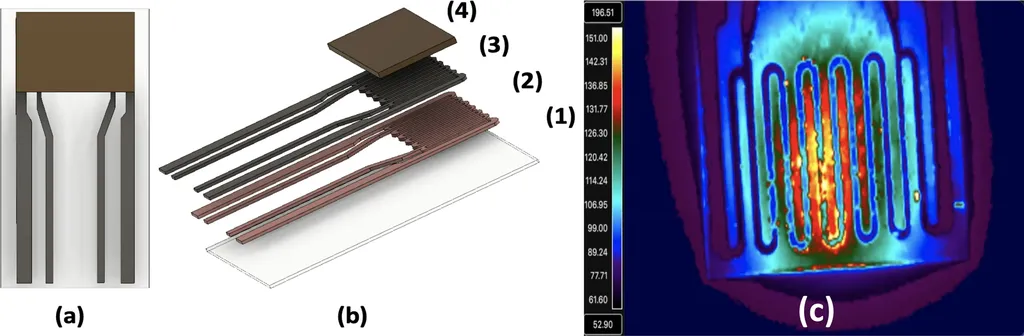

The team’s work, recently published in *Yantu gongcheng xuebao* (translated to English as *Rock and Soil Mechanics*), focuses on the development of a uniform polyvinylidene fluoride (PVDF) thin-film pressure sensor. This sensor is designed to monitor gas explosion hazards with unprecedented precision. “The complexity of compressed gas explosion test environments and the irregularity of sensor installation surfaces have long posed challenges in accurately measuring explosion parameters,” explains Dr. Hong. “Our PVDF sensor addresses these issues head-on, providing a robust solution for assessing explosion damage to engineering protective structures.”

The sensor was calibrated using two distinct methods: a self-made sensor calibration device and a split Hopkinson pressure bar (SHPB) calibration device. The results were remarkably consistent, with linear fitting degrees exceeding 0.95. This consistency is a testament to the sensor’s reliability and accuracy. “The PVDF sensor can accurately capture pressure changes and reconstruct the explosion shock process,” says Dr. Hong. “Its high response speed and stability make it a game-changer in the field of compressed gas explosion monitoring.”

To validate their findings, the researchers conducted experiments simulating explosion scenarios using instantaneous explosions of compressed gas balloons in the air. By adjusting the thickness of the balloons, they controlled the explosion intensity, and by varying the position of the explosion point, they studied the explosion pressure in the compressed air field. The results were compelling, demonstrating the sensor’s ability to perform better than traditional piezoelectric ceramic sensors.

The implications of this research are far-reaching, particularly for the energy sector. Underground energy infrastructure, such as pipelines and storage facilities, often operates in environments where gas explosions pose a significant risk. Accurate monitoring of these environments is crucial for preventing catastrophic failures and ensuring the safety of personnel and equipment. The PVDF thin-film pressure sensor developed by Dr. Hong and his team could play a pivotal role in enhancing the safety and efficiency of these operations.

As the energy sector continues to evolve, the need for advanced monitoring technologies will only grow. The research conducted by Dr. Hong and his colleagues at Zhejiang University represents a significant step forward in this field. Their work not only advances our understanding of gas explosion dynamics but also provides a practical tool for improving safety in underground structures. As the industry looks to the future, the PVDF thin-film pressure sensor stands out as a beacon of innovation, poised to shape the next generation of safety monitoring technologies.