In the quest for lighter, stronger, and more efficient materials, researchers have long been exploring the potential of magnesium alloys. A recent study published in *Academia Materials Science* (translated as “Academia of Materials Science”) by Manping Li from the National Engineering Research Center for Equipment and Technology of Cold Strip Rolling at Yanshan University in China, sheds new light on how innovative annealing techniques could revolutionize the production of magnesium alloys, particularly AZ91D, which is widely used in aerospace, electronics, and automotive manufacturing.

Traditionally, AZ91D magnesium alloy has been plagued by anisotropy after rolling, necessitating long-term annealing treatments to improve its properties. This process, while effective, is time-consuming and costly, hindering production efficiency. Enter pulse current annealing, a method that has been gaining traction for its efficiency and eco-friendliness. Li’s research delves into the comparative effects of electrical pulse annealing and conventional annealing on the microstructure and mechanical properties of AZ91D magnesium alloy.

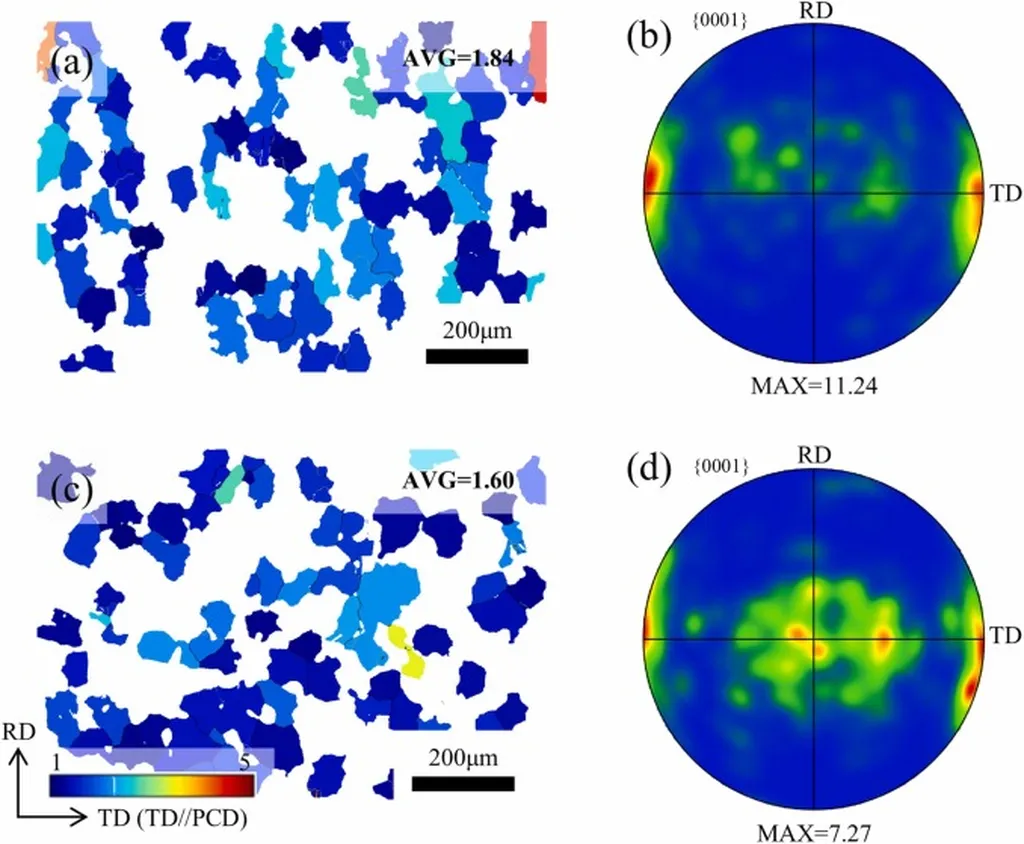

The findings are promising. Pulse current annealing can be completed quickly at lower temperatures, offering a significant advantage over conventional methods. “We found that pulse current annealing not only refines the grain size but also enhances the tensile strength and elongation of the samples,” Li explains. Specifically, at an optimal parameter of 123 A/mm², the grain size was refined to 65.37 μm, with a 32.70% increase in tensile strength and a 20.65% increase in elongation compared to conventional annealing.

The implications for the energy sector are substantial. Lighter materials mean reduced energy consumption in transportation, a critical factor in the push for more sustainable and efficient vehicles. “This technology provides a new, efficient, green production solution,” Li notes. The potential for widespread application is immense, with pulse current annealing offering a faster, more cost-effective, and environmentally friendly alternative to traditional methods.

As the world continues to seek innovative solutions to reduce energy consumption and improve efficiency, research like Li’s offers a glimpse into the future of materials science. The shift towards pulse current annealing could mark a significant step forward, not just in the production of magnesium alloys, but in the broader push for sustainable and efficient manufacturing practices. With further research and development, this technology could well become a cornerstone of modern industrial processes, shaping the future of the energy sector and beyond.