In the relentless battle against biofouling—a persistent challenge for industries ranging from maritime to energy—researchers have made a significant stride. A recent study published in *Macromolecular Materials and Engineering* (or, in English, *Macromolecular Materials and Engineering*) reveals how the strategic design of polyurethane coatings can dramatically enhance their fouling-release properties. The key? A delicate balance of hydrophilic and hydrophobic domains.

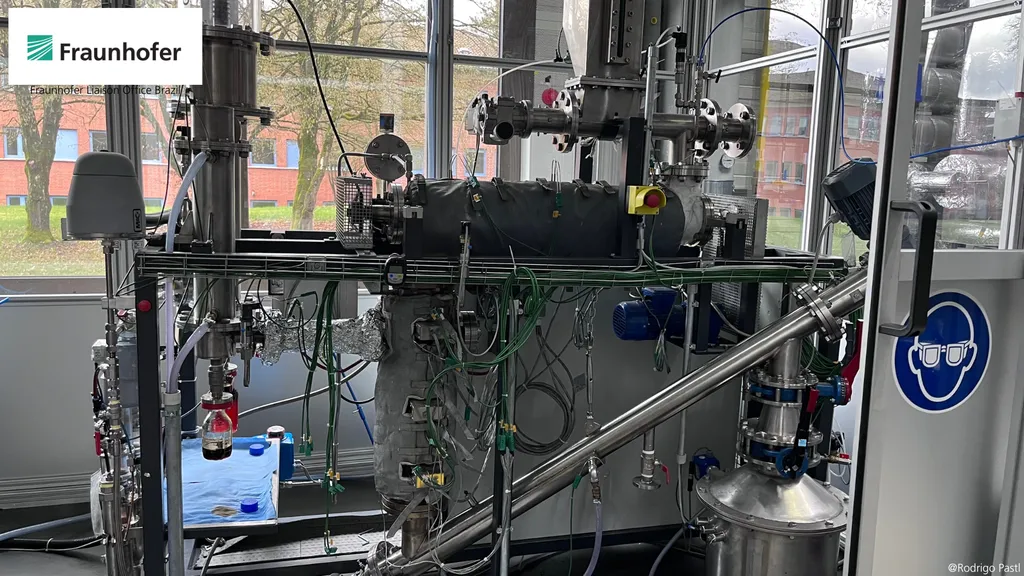

At the helm of this research is Johann C. Schaal, a scientist at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) in Bremen, Germany. Schaal and his team have demonstrated that by incorporating specific additives—both hydrophilic (mPEG-305) and hydrophobic (PDMS)—into polyurethane coatings, they can create surfaces with unique microstructures that actively repel biofouling.

The team’s approach involved modifying soft polyurethane coatings with these additives, resulting in surfaces that exhibit a range of polarity gradients. “We observed that the most effective coatings had a pronounced polarity gradient, with contact angle changes of up to 15° over time,” Schaal explains. This dynamic hydrophilicity, combined with microstructural heterogeneity, proved crucial in enhancing the coatings’ bio-repulsive properties.

The study’s findings are particularly relevant for the energy sector, where biofouling can lead to significant operational inefficiencies and maintenance costs. For instance, offshore platforms and wind turbines often face challenges related to biofouling, which can impede performance and increase downtime. The development of advanced fouling-release coatings could mitigate these issues, offering a more sustainable and cost-effective solution.

Schaal’s research highlights the importance of understanding the interplay between surface chemistry and microstructure. “The formation of two-phase systems with distinct morphologies—such as spherical hydrophobic domains and characteristic ‘wrinkled’ structures—plays a pivotal role in enhancing the coatings’ performance,” he notes. These microstructures not only improve the coatings’ ability to repel biofouling but also contribute to their durability and longevity.

The implications of this research extend beyond the energy sector. Industries such as maritime, aquaculture, and even medical devices could benefit from the development of advanced fouling-release coatings. By tailoring the surface properties of materials, researchers can create solutions that are both effective and environmentally friendly.

As the world continues to seek sustainable and innovative solutions to industrial challenges, Schaal’s work offers a promising avenue for exploration. The study not only advances our understanding of fouling-release mechanisms but also paves the way for future developments in material science and engineering. With further research and development, these coatings could become a standard in industries where biofouling poses a significant threat.

In the words of Schaal, “This research underscores the critical influence of polarity gradients, microstructural heterogeneity, and dynamic hydrophile behavior on the bio-repulsivity of polyurethane coatings.” As industries strive for greater efficiency and sustainability, such insights will be invaluable in shaping the future of material design and application.