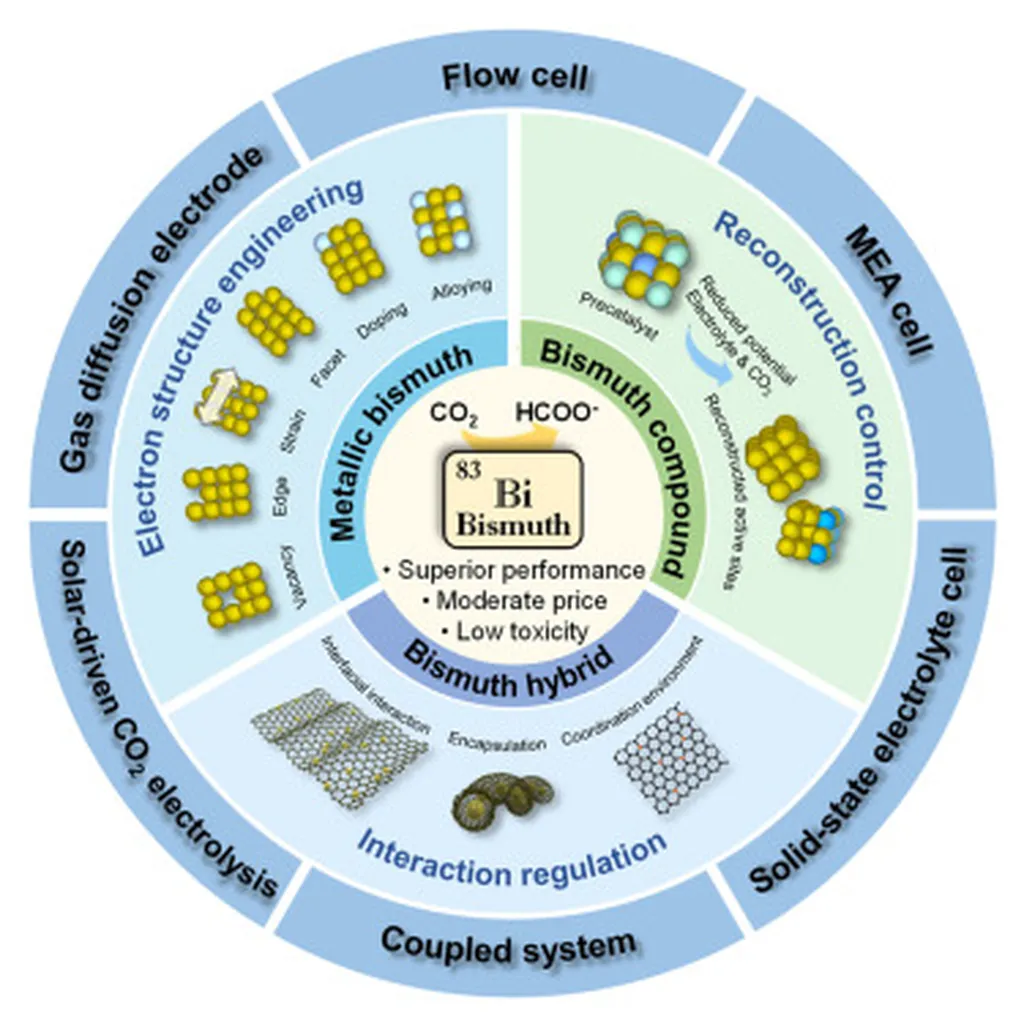

In a significant stride towards advancing electrochemical CO2 reduction (eCO2R) technology, researchers have uncovered a novel restructuring mechanism in bismuth-based catalysts that could revolutionize the production of formic acid in acidic electrolytes. This breakthrough, published in the journal *Small Science* (translated as “Small Science”), offers promising implications for the energy sector, particularly in carbon capture and utilization.

The study, led by Ganwen Chen from the Joint School of National University of Singapore and Tianjin University International Campus, focuses on the restructuring of bismuth (Bi)-based catalysts during electrocatalysis. The team discovered that different Bi-based compounds exhibit distinct restructuring behaviors, which significantly impact their electrochemical performance.

“Our research reveals that the unique structure of the Bi9O7.5S6 precatalyst, featuring stacking of [Bi2O2]2+ and [BiS2]− layers, plays a crucial role in enhancing the selectivity and activity for formic acid production,” Chen explained. This finding contrasts with the conventional Bi2O2S catalyst, which has alternating [Bi2O2]2+ layers with S2− ions and delivers inferior eCO2R performances.

The team employed quasi-in-situ X-ray diffraction and in-situ Raman spectroscopy to investigate the restructuring mechanisms. They found that metal elements situated between two [Bi2O2]2+ layers can resist decomposition and prevent the over-reduction of catalysts. This leads to the formation of a Bi/Bi2O2CO3 composite material with an active Bi-Bi2O2CO3 interface, which is highly effective for formic acid production.

The Bi9O7.5S6 precatalyst demonstrated remarkable performance, achieving a Faraday efficiency above 95% at 100 mA cm−2 and maintaining stability for 117 hours in a flow cell. These results highlight the potential of this catalyst to enhance the efficiency and durability of eCO2R processes in acidic electrolytes.

The implications of this research extend beyond the laboratory. Formic acid is a valuable chemical with applications in various industries, including fuel cells, pharmaceuticals, and agriculture. The ability to produce formic acid efficiently from CO2 not only contributes to carbon capture efforts but also opens up new avenues for sustainable chemical manufacturing.

As the energy sector continues to seek innovative solutions for reducing carbon emissions, this breakthrough in eCO2R technology offers a promising pathway towards a more sustainable future. The insights gained from this study could pave the way for the development of advanced catalysts and processes that enhance the efficiency and scalability of CO2 reduction technologies.

In the words of Chen, “This research not only advances our understanding of the restructuring mechanisms in Bi-based catalysts but also provides a foundation for the design of more effective catalysts for eCO2R in acidic environments.” The journey towards a carbon-neutral future is fraught with challenges, but with each scientific discovery, we inch closer to turning the tide on climate change.