In the heart of Ethiopia, researchers are stirring up a revolution in materials science that could significantly impact industries ranging from aerospace to maritime. Mekonnen Girma Dimbushe, a mechanical engineering researcher from Adama Science & Technology University, has been leading an investigation into copper matrix hybrid composites that promise to enhance the properties of pure copper, making it more suitable for high-performance applications.

The study, published in *Discover Materials* (translated from Amharic as “Uncovering Materials”), focuses on fabricating a silicon carbide-reinforced copper matrix hybrid composite with the addition of graphite (Gr) and chromium (Cr) to improve wettability between molten copper and solid reinforcement. “We aimed to enhance the properties of copper, which is already an excellent conductor of heat and electricity, but lacks strength and wear resistance,” Dimbushe explains.

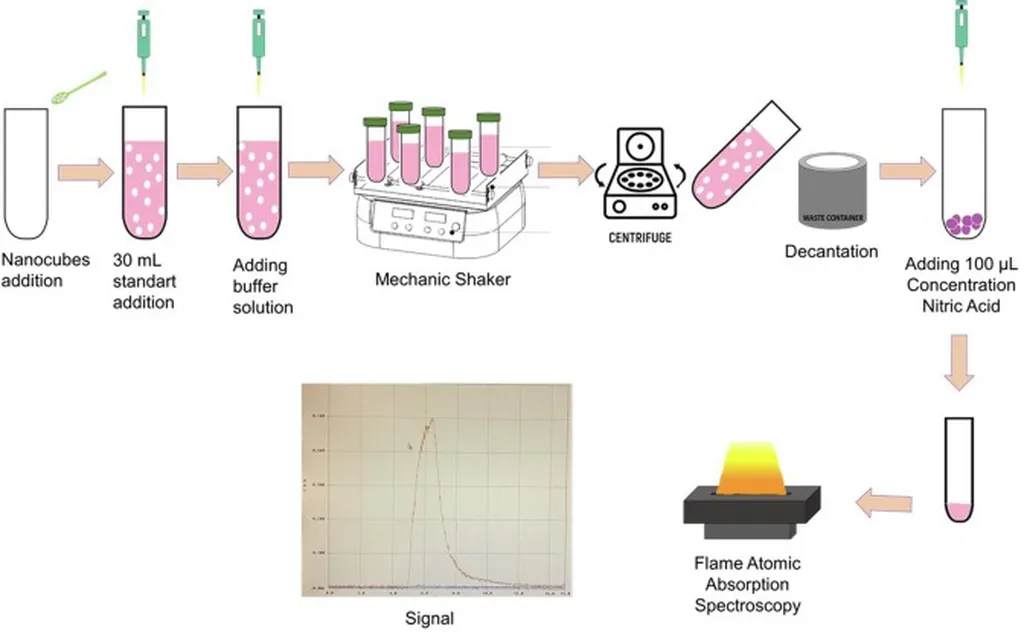

The team synthesized five samples using stir casting, varying the weight percentage of silicon carbide (SiC) from 0 to 12%. The results were promising. The addition of SiC-Gr-Cr improved hardness and corrosion resistance compared to commercial copper. Moreover, the compression strength increased with the addition of SiC-Gr-Cr up to 12% by weight. However, when the reinforcement approached 15%, the compressive strength decreased due to increased brittleness.

“This research opens up new possibilities for the energy sector,” says Dimbushe. “Imagine heat exchangers and resistance welding electrodes that are not only highly conductive but also stronger and more resistant to wear and corrosion. This could lead to more efficient and durable energy systems.”

The implications for the energy sector are substantial. Copper is already a critical material in power generation, transmission, and distribution. Enhancing its properties could lead to more efficient and reliable energy infrastructure. For instance, in heat exchangers, improved strength and corrosion resistance could extend the lifespan of the equipment, reducing maintenance costs and downtime.

In the maritime industry, where corrosion is a significant challenge, these enhanced copper composites could be a game-changer. They could be used in various components exposed to harsh marine environments, improving their durability and performance.

The study also highlights the importance of optimizing the reinforcement content. While increasing the SiC-Gr-Cr content up to 12% improved the properties, further increases led to a decrease in compressive strength due to brittleness. This balance is crucial for practical applications.

As the world continues to seek materials that are not only high-performing but also sustainable and cost-effective, Dimbushe’s research offers a promising avenue. It underscores the potential of copper matrix hybrid composites to meet the evolving needs of various industries, particularly in the energy sector.

In the words of Dimbushe, “This is just the beginning. There’s so much more to explore and discover in the world of materials science.” And with each discovery, we edge closer to a future where materials are not just functional but also resilient and sustainable.