In a groundbreaking study published in the journal *Materials Research* (formerly known as *Revista Brasileira de Materiais e Minerais*), researchers have demonstrated a simple yet effective method to enhance the mechanical properties of PLA/wood composites used in additive manufacturing. The findings, led by Frederico de Castro Magalhães, could have significant implications for the energy sector and beyond.

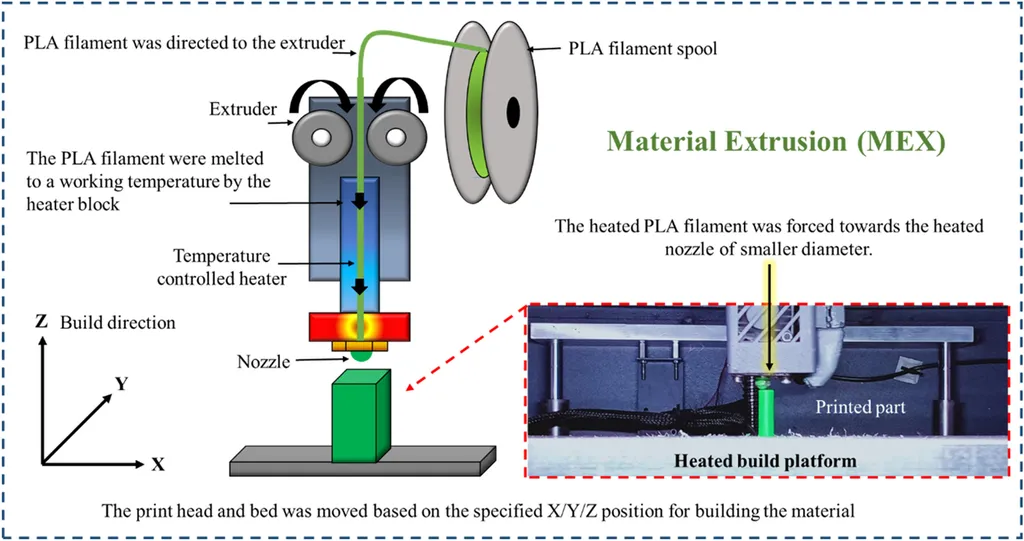

The research focused on improving the performance of PLA/wood composites, which are increasingly used in various industries due to their sustainability and cost-effectiveness. The team investigated the impact of annealing— a heat treatment process—on the mechanical and structural properties of these composites. The material consisted of PLA reinforced with 20% recycled pine particles, printed using fused deposition modeling (FDM) in two different raster orientations: 0°/90° and −45°/45°.

Annealing was performed at a relatively low temperature of 50 °C for one hour, a temperature carefully chosen to promote molecular relaxation at the interlayer regions without altering the external geometry of the printed parts. “We wanted to find a sweet spot where we could improve the material’s properties without compromising its dimensional stability,” explained Magalhães.

The results were impressive. The void content in the composites decreased from approximately 12.7% to 11.4%, and the Shore D hardness increased by about 2%. More significantly, the tensile strength saw a substantial rise from 17.83 to 28.95 MPa for the 0°/90° orientation and from 16.55 to 27.58 MPa for the −45°/45° orientation. Flexural strength increased by up to 48%, and Charpy impact resistance also showed notable improvements.

Microscopy revealed that annealing reduced interlayer separation and resulted in more cohesive fracture paths, indicating a stronger and more durable material. “The improvements in mechanical properties are not just incremental; they are substantial and could open up new possibilities for the use of these composites in high-performance applications,” said Magalhães.

The energy sector, in particular, stands to benefit from these advancements. PLA/wood composites are already being used in various applications, from wind turbine components to building materials. The enhanced mechanical properties achieved through annealing could make these materials more reliable and durable, reducing maintenance costs and improving overall performance.

This research not only highlights the potential of annealing as a post-processing technique but also underscores the importance of optimizing material properties for specific applications. As the demand for sustainable and cost-effective materials continues to grow, innovations like these will play a crucial role in shaping the future of additive manufacturing and the energy sector.

The study, published in *Materials Research*, provides a compelling case for further exploration of annealing and other post-processing techniques to unlock the full potential of PLA/wood composites. With continued research and development, these materials could become even more versatile and widely adopted across various industries.