In the heart of Nanjing, China, researchers are redefining the future of construction materials, with implications that ripple through the energy sector. Xiaoqian Wang, a leading figure from the School of Architectural Engineering at Jinling Institute of Technology, has been delving into the intricate world of PHC pipe pile concrete, a material known for its high strength but notorious brittleness. Her work, recently published in the journal *Materials Research Express* (translated as “Materials Research Express”), is shedding new light on how manufacturing processes can significantly influence the performance of this crucial construction material.

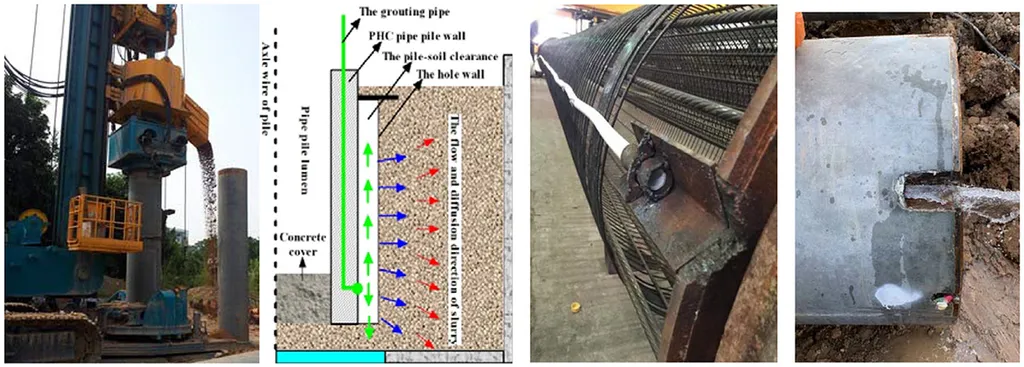

PHC pipe pile concrete is a staple in the energy sector, particularly in the construction of offshore wind farms and other large-scale infrastructure projects. However, its tendency to crack under pressure has long been a challenge for engineers. Wang’s research aims to address this issue by examining the effects of centrifugal forming and steam curing on the fracture properties of the concrete.

The study involved creating prismatic specimens using a self-designed centrifuge and subjecting them to three-point bending fracture experiments. To gain deeper insights, Wang and her team employed digital image correlation (DIC) and acoustic emission (AE) techniques. The results were revealing. “We found that reducing the delay period to 2 hours from 4 hours, or extending the duration beyond 12 hours at 80 °C, induces significant steam-related damage in concrete,” Wang explained. This damage leads to a decrease in flexural strength and crack initiation toughness, making the concrete more prone to cracking.

However, the story doesn’t end there. Wang’s research also uncovered the positive impact of centrifugal forming. “Centrifugal forming compacts the concrete mixture, lowers the water-cement ratio, enhances initial strength, and mitigates the negative effects of steam curing,” she noted. This finding provides a theoretical basis for reducing the delay period by approximately 2 hours compared to conventional concrete, a development that could significantly improve production efficiency in the PHC pipe pile manufacturing process.

The implications for the energy sector are substantial. By optimizing the manufacturing process, engineers could produce stronger, more resilient PHC pipe pile concrete, reducing the risk of cracking and enhancing the longevity of infrastructure projects. This could lead to more stable and efficient energy production, particularly in offshore environments where the integrity of foundations is paramount.

Wang’s research is a testament to the power of innovation in materials science. As she continues to explore the intricacies of PHC pipe pile concrete, her work is paving the way for advancements that could reshape the future of construction and energy production. For professionals in these fields, her findings offer a compelling glimpse into the potential of optimized manufacturing processes and the transformative impact they can have on the materials that underpin our infrastructure.