In a groundbreaking study published in the journal *Advances in Materials Science and Engineering* (translated from Arabic as “Advances in Materials Science and Engineering”), researchers have demonstrated that eggshell powder and wheat straw ash can partially replace cement in concrete, enhancing durability without sacrificing strength. This innovative approach could revolutionize the construction industry, particularly in the energy sector, where sustainable and cost-effective materials are in high demand.

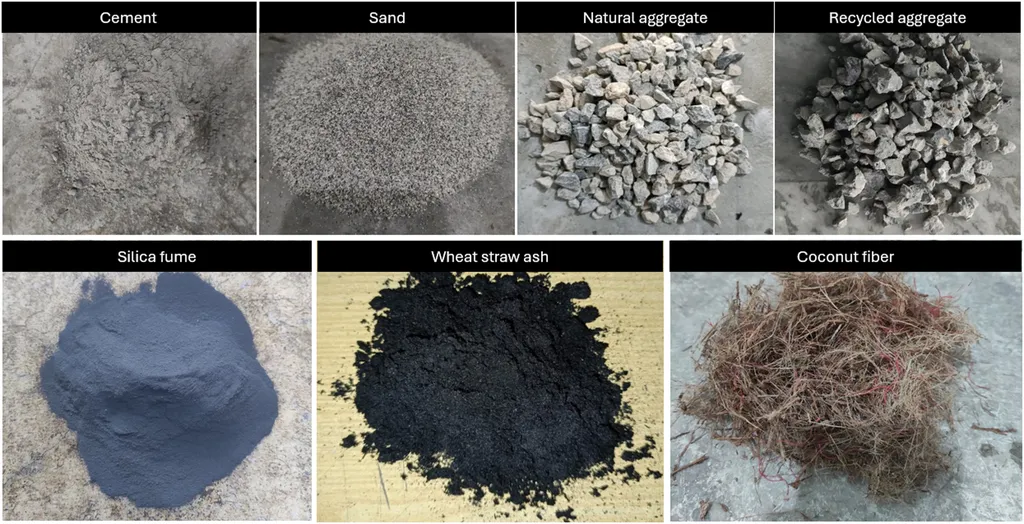

The study, led by Abdulsemad Jemal Jema from the Department of Civil Engineering, explores the potential of eggshell powder (ESP) and wheat straw ash (WSA) as partial replacements for ordinary Portland cement (OPC) in C-25 concrete. The research focuses on mechanical performance and durability, offering a promising solution to reduce the environmental impact of cement production.

“Our findings indicate that replacing 20% of cement with a blend of 15% eggshell powder and 5% wheat straw ash not only maintains the compressive strength of the concrete but also improves its resistance to sulfuric acid,” said Jema. This is a significant breakthrough, as sulfuric acid resistance is crucial for concrete used in industrial settings, including energy infrastructure.

The study involved a series of experimental tests, including consistency, workability, compressive and flexural strength, acid resistance, and microstructure analysis using scanning electron microscopy (SEM) and X-ray diffraction (XRD). The results showed that as the ESP–WSA content increased, the consistency of the concrete improved while workability decreased. However, the blend containing 15% ESP and 5% WSA achieved compressive strength comparable to the control mix, maintaining flexural strength as well.

One of the most compelling aspects of this research is its potential to reduce the carbon footprint of the construction industry. Cement production is a major contributor to global carbon emissions, and finding sustainable alternatives has been a priority for researchers worldwide. “By utilizing agrowaste materials like eggshells and wheat straw, we can significantly reduce the need for traditional cement, contributing to a more sustainable future,” Jema explained.

The microstructure analysis revealed a denser microstructure with reduced free lime, which is indicative of improved durability. XRD results further confirmed the pozzolanic activity of the ESP–WSA blend, showing lower portlandite content and inhibited ettringite formation. These findings suggest that the blend not only enhances the mechanical properties of concrete but also improves its long-term performance.

The implications of this research are far-reaching, particularly for the energy sector. Concrete is a fundamental material in the construction of energy infrastructure, including power plants, wind turbines, and solar farms. The use of sustainable and durable concrete can reduce maintenance costs and extend the lifespan of these structures, making them more economically viable and environmentally friendly.

As the construction industry continues to seek innovative solutions to reduce its environmental impact, the findings of this study offer a promising path forward. By incorporating agrowaste materials into concrete mixes, we can create more sustainable and durable structures, paving the way for a greener future.

“This research highlights the importance of exploring alternative materials in construction,” Jema concluded. “It’s not just about reducing costs; it’s about creating a more sustainable and resilient built environment.”