In the ever-evolving landscape of materials science, a groundbreaking study led by Ioana-Cristina Băncilă from the Vienna University of Technology (TU Wien) is set to revolutionize how we understand and characterize materials, with significant implications for the energy sector. Published in the journal “Advances in Mechanical and Materials Engineering” (which translates to “Fortschritte in der Mechanik und Werkstofftechnik”), the research delves into the intricacies of nanoindentation, a method crucial for mapping the mechanical properties of heterogeneous materials.

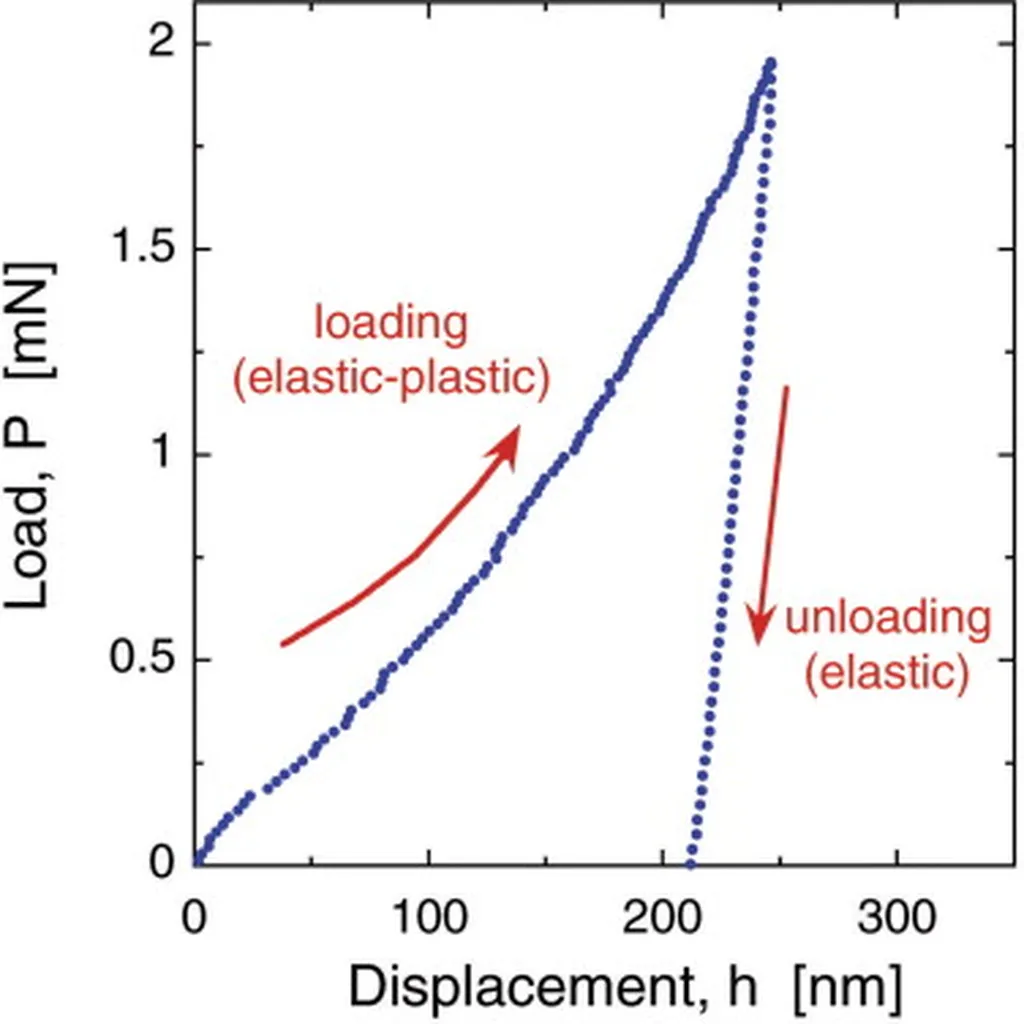

Nanoindentation, a technique that involves pressing a tiny, hard tip into a material to measure its mechanical properties, has been around for decades. However, the method has faced challenges in terms of reproducibility and interpretability. Băncilă and her team have tackled these issues head-on, proposing a standardized workflow that integrates Atomic Force Microscopy (AFM), Density Functional Theory (DFT), and Finite Element Method (FEM) into a single sequence. This innovative approach enables cross-validation between computational, experimental, and quantum mechanical methods, providing a comprehensive characterization of materials from the macroscale to the nanoscale.

“The novelty of our work lies in the proposed workflow,” Băncilă explains. “By integrating these different methods, we can achieve a more holistic understanding of material properties, which is crucial for applications in the energy sector and beyond.”

The energy sector, in particular, stands to benefit significantly from this research. Understanding the mechanical properties of materials at the nanoscale is essential for developing advanced energy storage solutions, improving the efficiency of solar cells, and enhancing the durability of materials used in harsh environments, such as those found in geothermal and offshore wind energy applications.

Moreover, the proposed workflow serves as a standardized guideline that can enhance reproducibility and interpretability of material properties. This is a game-changer for interdisciplinary projects, making it easier for researchers from different fields to collaborate and build upon each other’s work.

“The potential applications are vast,” Băncilă adds. “From biomedical engineering to energy materials, this workflow can provide a robust framework for characterizing and understanding material properties at the nanoscale.”

As the energy sector continues to evolve, the need for advanced materials that can withstand extreme conditions and perform efficiently becomes ever more critical. This research not only addresses current challenges in nanoindentation but also paves the way for future developments in materials science, with far-reaching implications for the energy industry.

In a field where precision and reliability are paramount, Băncilă’s work offers a beacon of innovation, guiding researchers and industry professionals towards a future where materials are not just understood but optimized for their intended applications. The journey towards this future starts with a single, well-characterized material—and this research provides the map.