In the quest for more efficient photocatalysts to tackle environmental pollutants, researchers have turned to a familiar material: titanium dioxide (TiO2). But this time, they’ve added a twist—nickel doping. A recent study led by Dounia Adnane from the Ceramic Laboratory at Constantine 1 University in Algeria has shed light on how nickel doping affects the structural, surface, and photocatalytic properties of TiO2 thin films. The findings, published in *Materials Research Express* (which translates to *Expressions of Materials Research*), could have significant implications for the energy sector, particularly in developing more effective photocatalytic materials for environmental applications.

Adnane and her team synthesized nickel-doped TiO2 thin films using the sol-gel dip-coating technique, a method known for its simplicity and cost-effectiveness. The films were deposited onto Si(001) substrates and annealed at 900 °C for 2 hours. The researchers varied the nickel concentration, creating films with 0, 2, and 7 atomic percent nickel.

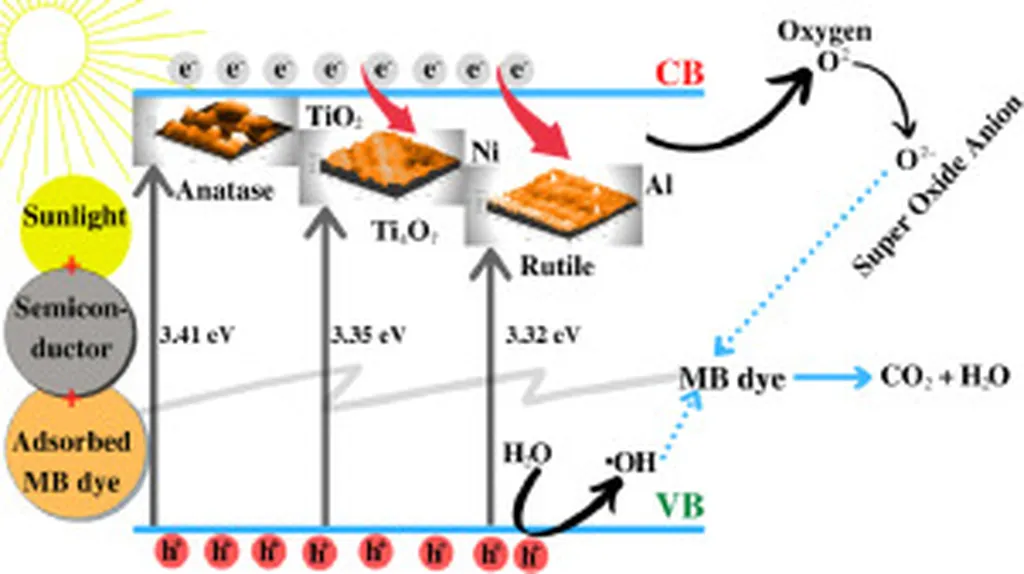

Structural analysis revealed that the films contained a mix of anatase, rutile, and NiTiO3 phases, regardless of the nickel content. “Increasing the nickel content reduced the crystallite size of anatase while promoting the growth of rutile and NiTiO3 phases,” Adnane explained. This structural evolution is crucial as it directly impacts the material’s surface properties and, consequently, its photocatalytic performance.

Morphological studies showed that NiTiO3 preferentially formed at the grain boundaries between anatase and rutile, significantly altering the surface structure. Electrostatic force microscopy (EFM) analysis demonstrated a decrease in surface potential from 1.3 V to 0.6 V with increasing nickel content. “This suggests enhanced electron-hole recombination,” Adnane noted, a factor that could potentially limit the material’s photocatalytic efficiency.

The team evaluated the photocatalytic performance of the films by measuring the degradation of Rhodamine B (RhB) dye under UV irradiation. Pure TiO2 films exhibited the highest activity, with a degradation efficiency of 51% after 6 hours. However, nickel incorporation led to a reduction in photocatalytic efficiency.

While the findings might seem counterintuitive—given that nickel doping reduced photocatalytic activity—they offer valuable insights into the complex interplay between structural, surface, and electronic properties of TiO2 thin films. “Understanding these relationships is crucial for developing more efficient photocatalysts,” Adnane stated.

The study’s implications extend beyond academic interest. In the energy sector, photocatalysts play a vital role in environmental remediation, water purification, and even energy generation through processes like photoelectrochemical water splitting. The insights gained from this research could guide the development of next-generation photocatalytic materials tailored for specific applications.

As Adnane and her team continue to explore the nuances of nickel doping, their work serves as a reminder that even small changes in material composition can have profound effects on performance. In the ever-evolving field of materials science, such discoveries are the building blocks of future innovations.