In the fast-paced world of construction and infrastructure, efficiency and cost-effectiveness are paramount. A recent study published in *Zhongwai Gonglu* (which translates to *China and Foreign Highway*) introduces a groundbreaking testing method that could revolutionize the way we assess under-anchor tension in prestressed concrete girders. Led by ZHU Jianzhao of the Ningbo Traffic Construction Engineering Test and Testing Center Co., Ltd., this research promises to streamline testing processes, reduce costs, and enhance the reliability of infrastructure projects.

The study focuses on a novel approach called whole-hole back-pull testing technology. This method is designed to address the significant challenges posed by large testing volumes and tight project schedules. By optimizing the traditional back-pull method, ZHU and his team have developed a more efficient and accurate way to measure under-anchor tension, a critical factor in the structural integrity of prestressed concrete girders.

“Our goal was to create a testing method that not only reduces the time and cost associated with traditional techniques but also maintains a high level of accuracy,” said ZHU Jianzhao. “The whole-hole back-pull testing technology achieves this by simplifying the mechanical model and providing a more straightforward formula for determining under-anchor tension.”

The research involved a comprehensive theoretical analysis and formula derivation, followed by experimental validation. The results were impressive, with a testing deviation rate within 10% and minimal impact on existing under-anchor tension. This level of precision is crucial for ensuring the safety and longevity of infrastructure projects, particularly in the energy sector where large-scale constructions are common.

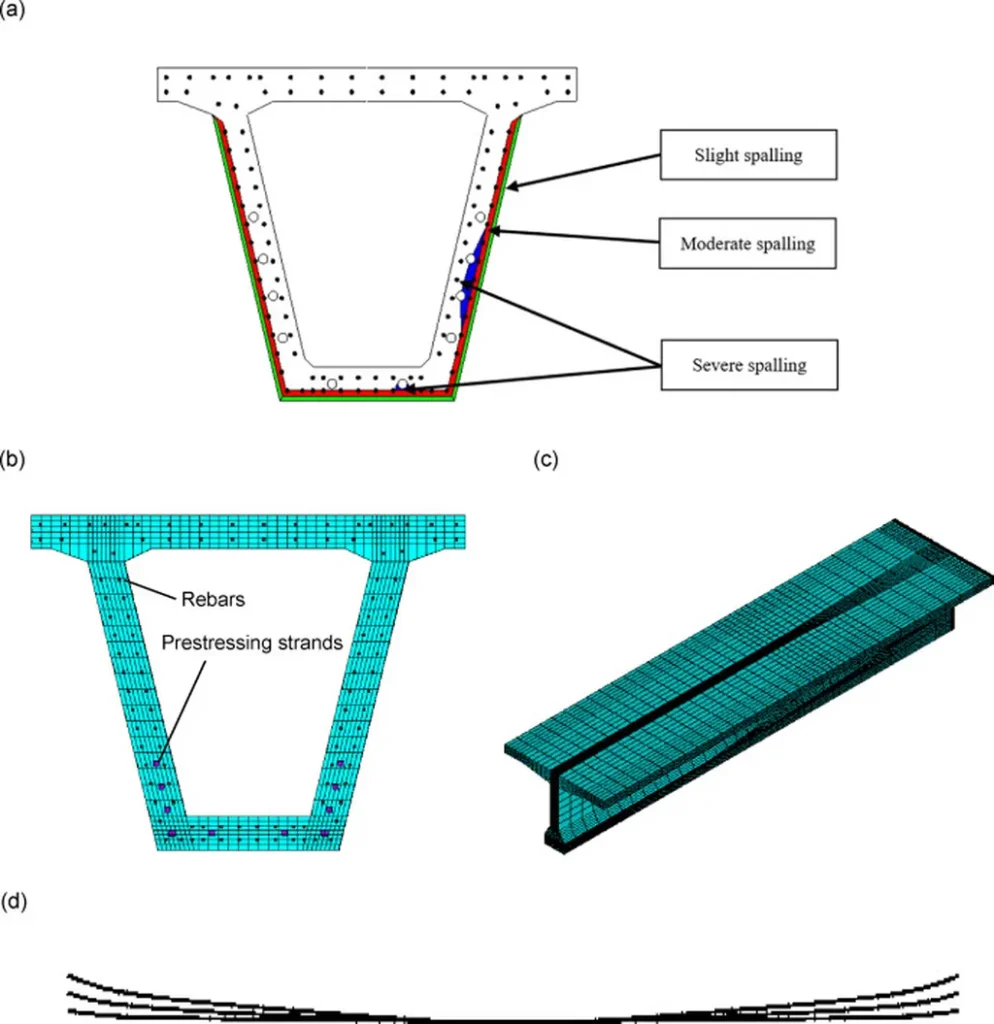

The simplified mechanical model and typical test curves obtained from this study provide a clear framework for applying the whole-hole back-pull testing technology in real-world scenarios. The proposed formula for determining under-anchor tension based on test curve regularity offers a practical tool for engineers and construction professionals.

While the study demonstrates the feasibility of this new testing method, there is still room for improvement. ZHU Jianzhao acknowledges that further enhancements in testing equipment and consideration of environmental factors could further refine the accuracy of the technique. “We are excited about the potential of this technology,” he added. “With continued research and development, we believe it can become a standard practice in the industry.”

The implications of this research are far-reaching. For the energy sector, where large-scale infrastructure projects are common, the adoption of whole-hole back-pull testing technology could lead to significant cost savings and improved project timelines. By reducing the time and resources required for testing, construction companies can allocate their budgets more effectively, ultimately benefiting both the industry and the end-users.

As the construction industry continues to evolve, innovative technologies like the whole-hole back-pull testing method will play a pivotal role in shaping the future of infrastructure development. The work of ZHU Jianzhao and his team, published in *Zhongwai Gonglu*, represents a significant step forward in this direction, offering a glimpse into a more efficient and reliable future for construction and engineering.