In the heart of Japan’s Ibaraki Prefecture, researchers at the National Institute for Materials Science (NIMS) are pushing the boundaries of materials science with a novel approach to automated synthesis. Led by Wei-Sheng Wang, a team of scientists has developed a robotic system that could revolutionize how we explore and validate new materials, particularly for the energy sector.

The team’s work, published in the journal *Science, Technology and Advanced Materials: Methods* (which translates to *Science and Technology of Advanced Materials: Methods* in English), focuses on the automated synthesis of bulk intermetallic materials using a technique called arc melting. This process involves using an electric arc to melt and mix metals, creating new compounds with unique properties.

The challenge, as Wang explains, lies in the complexity and variety of processes involved in materials synthesis. “Traditionally, these tasks are labor-intensive and time-consuming,” he says. “Human error can also creep in, and the process can be quite repetitive. Our goal was to automate this to increase throughput and accuracy.”

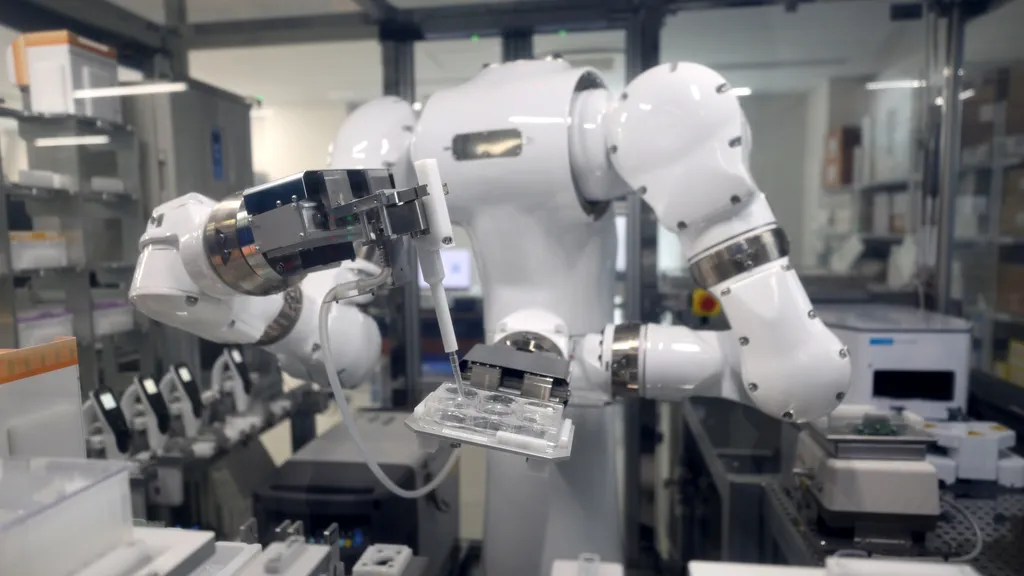

The solution? A robotic system controlled by Robot Operating System 2 (ROS2). This open-source framework allows for the orchestration of multiple experimental apparatuses simultaneously, with the flexibility to expand functions as needed. The system can handle multiple elements for the synthesis of intermetallic compounds, performing repeated operations with precision.

The implications for the energy sector are significant. Intermetallic compounds are crucial in developing advanced materials for energy applications, such as more efficient catalysts for fuel cells or more robust materials for nuclear reactors. By automating the synthesis process, researchers can quickly validate the properties of these materials, accelerating the development of new energy technologies.

Moreover, the system’s flexibility means it can be adapted to other synthesis methods beyond arc melting. This adaptability could open up new avenues for materials exploration, making the process faster, more efficient, and less prone to error.

As Wang puts it, “This is not just about automating a single task. It’s about creating a flexible, scalable system that can handle the complexity of materials synthesis. It’s a significant step towards data-driven materials exploration.”

The research is a testament to the power of integrating robotics and informatics into materials science. By automating the synthesis process, researchers can focus more on the creative aspects of their work, driving innovation in the field. And with the energy sector’s growing demand for advanced materials, this development could not have come at a better time.

In the words of Wang, “We’re not just building machines. We’re building a future where materials science can keep up with the pace of innovation.”