In a groundbreaking development that could reshape the future of welding in the energy sector, researchers have discovered a method to create welds stronger than the base metal itself. This innovation, published in the journal *Materials Research Letters* (translated as *Materials Research Letters*), challenges long-held assumptions about the inherent weaknesses of welds in face-centered cubic (FCC) alloys.

At the heart of this research is Yoona Lee, a materials scientist from the Department of Materials Science and Engineering at Pusan National University in Busan, South Korea. Lee and her team have uncovered a way to exploit compositional and spatial heterogeneity in weld metal to enhance its performance, particularly in cryogenic environments.

“Traditionally, welds in FCC alloys have been weaker and more prone to failure than the base metal,” Lee explained. “Our approach flips this script by using the very inhomogeneities that typically weaken welds to our advantage.”

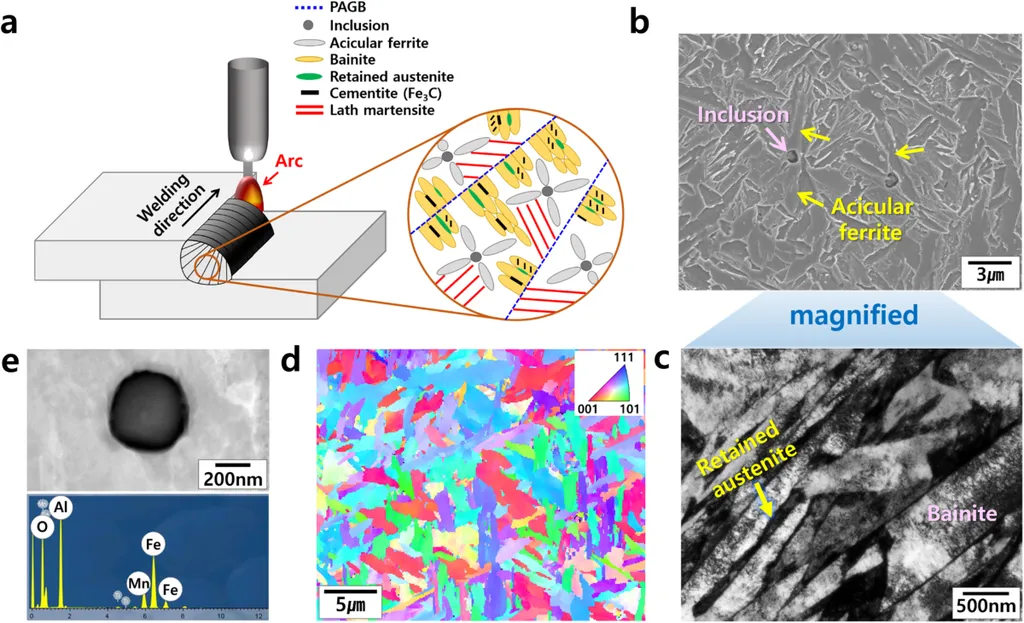

The key to this breakthrough lies in the preferential promotion of deformation-induced martensitic transformation in the weld metal over the base metal. By reducing the FCC phase stability in the weld metal, the researchers activated a gradual progression of martensitic transformation from the weld metal toward the base metal. This process not only enhances the strength of the weld but also significantly improves its ductility.

The results are staggering. The welds developed by Lee’s team exhibit a 104% increase in cryogenic strength and a 140% improvement in ductility compared to the base metal. These advancements outperform state-of-the-art alloys currently available, offering a promising solution to the long-standing issue of weld degradation in extreme environments.

For the energy sector, the implications are profound. Cryogenic environments are critical in various energy applications, from liquefied natural gas (LNG) storage and transportation to advanced power generation systems. The ability to create welds that are stronger and more ductile than the base metal could lead to safer, more efficient, and more reliable infrastructure.

“This research opens up new possibilities for designing and manufacturing energy infrastructure that can withstand the harshest conditions,” Lee noted. “It’s a game-changer for industries that rely on high-performance materials.”

The findings published in *Materials Research Letters* not only address a fundamental scientific challenge but also pave the way for practical applications that could revolutionize the energy sector. As researchers continue to explore and refine these techniques, the future of welding in extreme environments looks brighter than ever.

In the broader context, this research highlights the importance of interdisciplinary collaboration and innovative thinking in materials science. By challenging conventional wisdom and leveraging advanced technologies, scientists like Yoona Lee are pushing the boundaries of what is possible, driving progress and shaping the future of industrial applications.